J-shaped ground track traversing garage device

A technology of traverse and garage, applied in the building types, buildings where cars are parked, buildings and other directions, can solve the problem of large road width and size, save the required space and reduce the difficulty of parking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

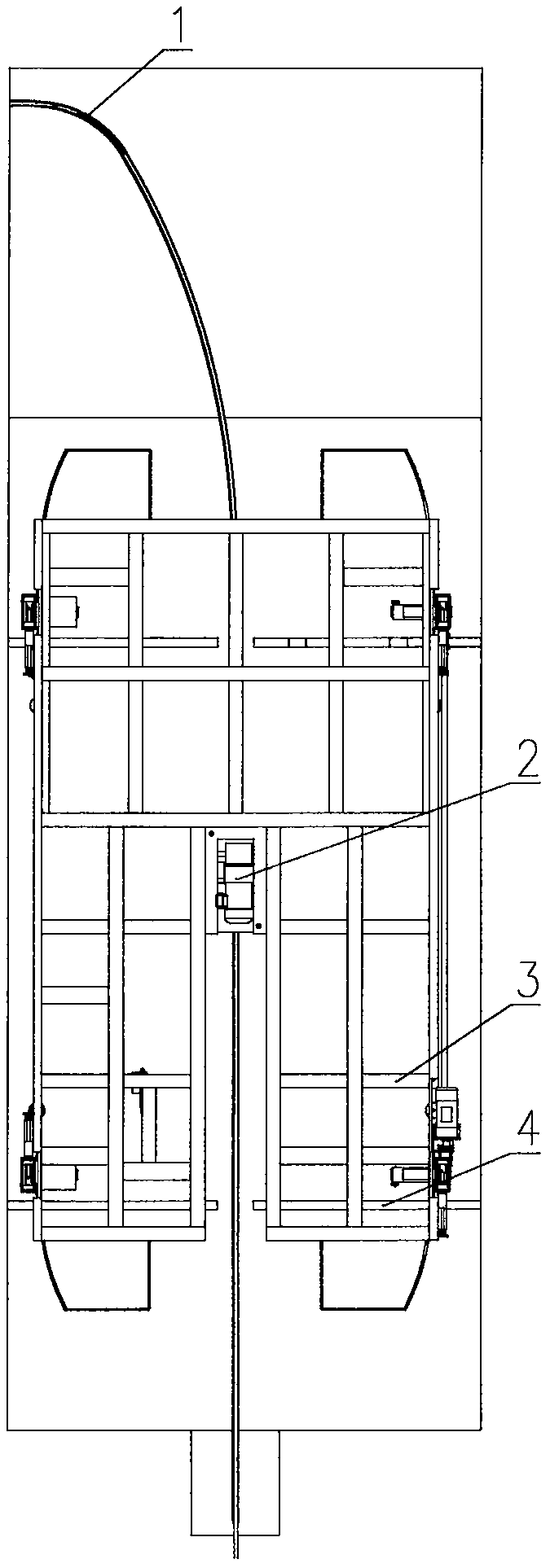

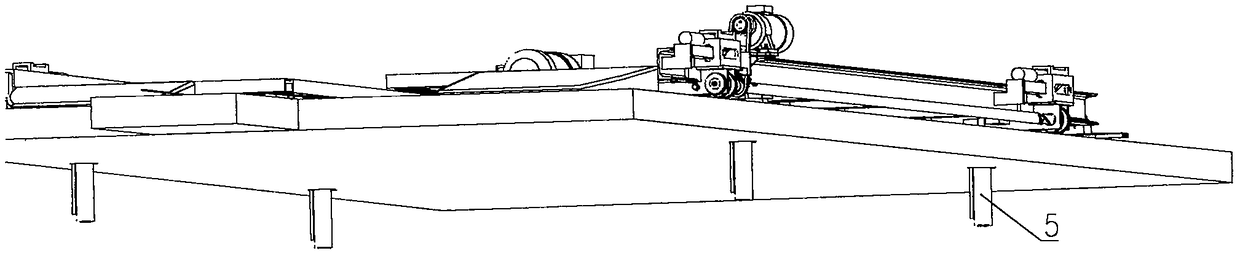

[0039] see figure 1 and figure 2 , schematically shows a preferred embodiment of the J-type ground rail traverse garage device provided by the present invention. As shown in the figure, the J-type ground rail traverse garage device mainly includes a J-type sprocket track system 1, a moving car System 2, car plate system 3, straight rail system 4 and jacking system 5;

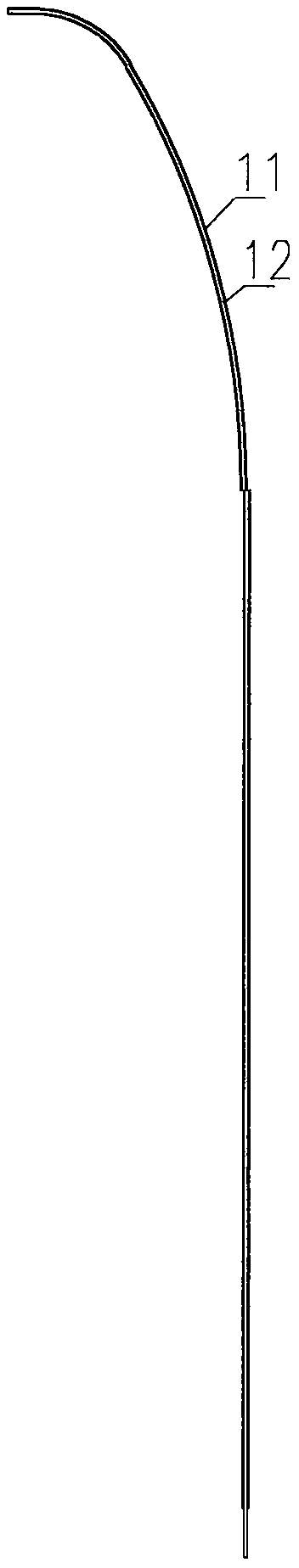

[0040] see image 3 , the J-shaped sprocket track system 1 mainly includes a sprocket rail 11 and a dust cover 12;

[0041] see Figure 4 , the moving trolley system 2 mainly includes a support plate 21, a positioning pin 22, a sprocket system 23, a clamp wheel system 24, a pressure wheel system 25, a supporting travel wheel system 26 and a motor 27;

[0042] see Figure 5 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com