Assembly welding device, assembly welding method and Charismas tree guide frame

A technology of Christmas trees and guide frames, which is applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as deformation of Christmas tree guide frames, low production efficiency, and irregular number and position of welds, so as to improve production efficiency and avoid The effect of gradually accumulating and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

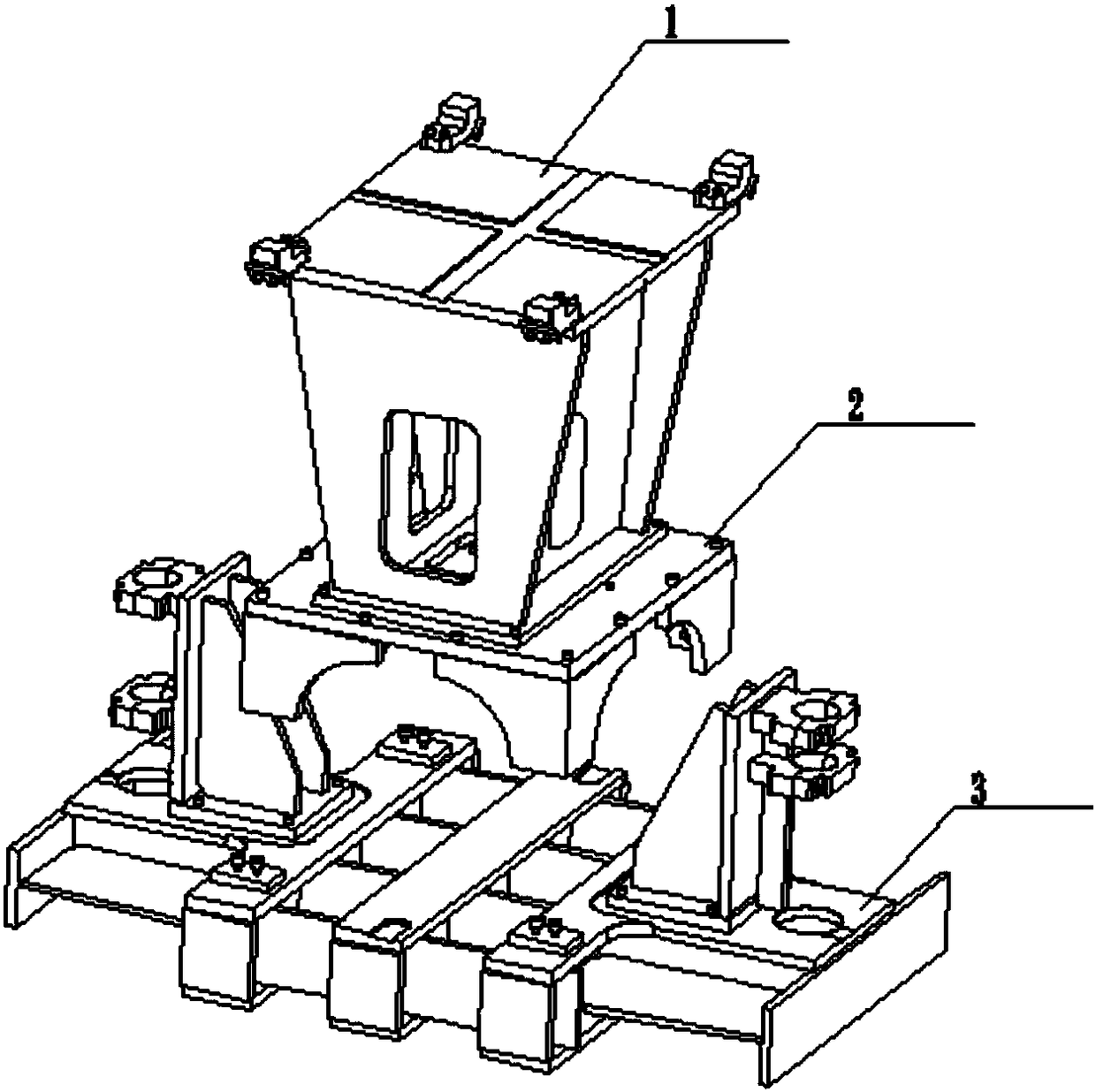

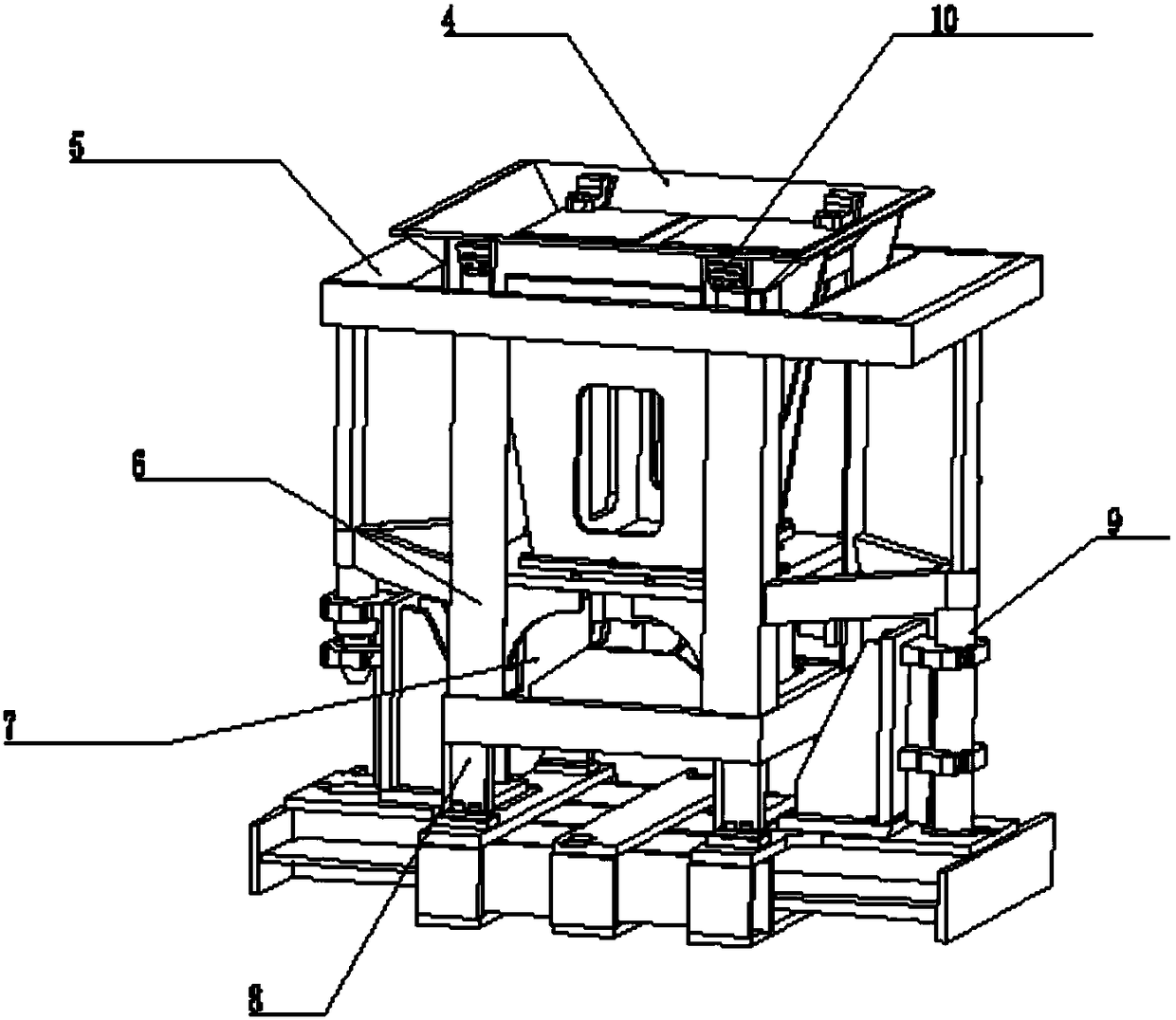

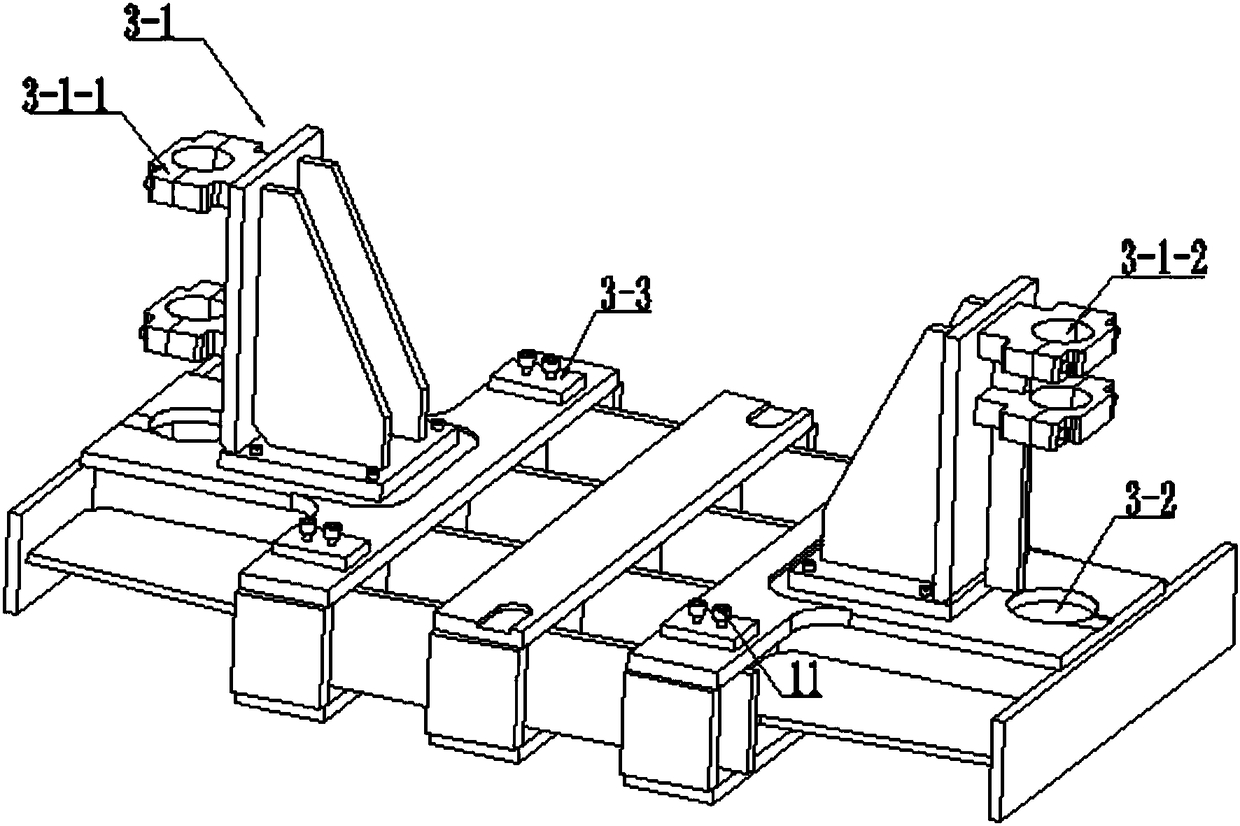

[0066] In a typical implementation of the present application, such as figure 1 , figure 2 As shown, the assembly welding device includes three parts: the base 3, the middle support assembly 2, and the top support assembly 1; connection, the top support assembly 1 is set on the upper part of the middle support assembly 2, the connection between the two can be selected to be connected together by bolts, of course, it can also be connected by welding, and the three parts of the welding assembly can be connected separately The bottom component 7 , the middle component and the upper component of the Christmas tree guide frame 5 are positioned and supported, thereby forming the overall positioning and support of the Christmas tree guide frame 5 .

[0067] The assembly welding device is set as a split structure, and the butt welding process of the Christmas tree guide frame 5 is completed on the tooling. During the butt welding process, the middle support assembly 2 and the top su...

Embodiment approach

[0092] In yet another embodiment, the fitting is a measuring rod slidingly fitted in the positioning groove, and the end of the measuring rod is provided with a measuring head, which may be a vertical line drawn from the end of the measuring rod or a device such as a laser.

[0093] It should be noted that in this embodiment, the positioning inspection device is a positioning groove 1-2, which is arranged on the top of the first support column. It can be understood that in other embodiments, it can also be adjusted according to specific working conditions. Set the form and location of the positioning inspection device.

[0094] The method for fast and efficient butt-welding of the Christmas tree guide frame 5 by using the assembly welding device disclosed in the present invention comprises the following steps:

[0095] (1) Preparatory process before assembly welding

[0096] Hoist the base 3 of the assembly welding device on the platform, check the flatness of the upper end s...

Embodiment 2

[0117] As a preferred solution, its difference from Embodiment 1 is:

[0118] Another positioning inspection device is provided on the assembly welding device. As an embodiment, the positioning inspection device can be a telescopic mechanism arranged on the upper part or one side of the first support column, and the telescopic mechanism can be a sliding or screw thread Cooperate with the first supporting base is a measuring rod, the measuring rod can be adjusted automatically or manually, the end of which is provided with a laser, and the laser beam emitted by the laser can be used to inspect the top support assembly 1, the middle support assembly 2 and the Whether the datums of the base 3 coincide, or inspect and measure the positioning dimensions of the components of the tree guide frame 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com