Binding resistor configuration structure for three-phase integrated on-load voltage regulation switch

A technology of voltage regulating switch and configuration structure, which is applied in the direction of electrical component structure association, transformer/inductor components, circuits, etc., can solve the problems of high voltage level of tap changer, difficult to handle insulation problems, and large size of binding resistance. , to achieve the effect of improving electrical performance, saving internal space, and meeting insulation distance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

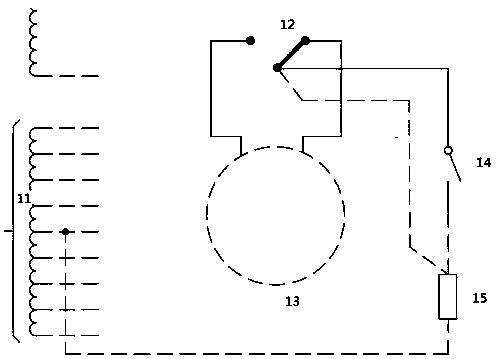

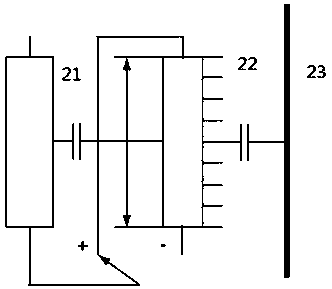

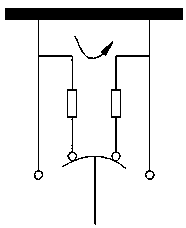

[0022] A tie resistor configuration structure for a three-phase integrated on-load tap changer, including A phase tie resistor 1, B phase tie resistor 2, C phase tie resistor 3, on-load tap changer 4, iron core lower web 5, and insulating support plate 6 and supporting wire clamp 7, the C-phase tie-up resistor 3 is arranged at the bottom of the on-load tap-changer 4, the A-phase tie-in resistor 1 and the B-phase tie-in resistor 2 are installed at the lower part of the on-load tap-changer 4, and the transformer core clip On the insulating support plate 6 of the component, the lower web plate 5 of the iron core is arranged at the lower end of the insulating support plate 6, and the vertical directions of the A-phase binding resistor 1, the B-phase binding resistor 2, and the C-phase binding resistor 3 are on the same horizontal plane, forming a "pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com