Method and device for correcting non-uniformity of infrared detector

An infrared detector and non-uniformity technology, applied in the field of infrared detectors, can solve the problems of low calibration efficiency, waste of human and material resources, and calibration accuracy difficult to meet high-precision application requirements, so as to improve efficiency and reduce waste of human resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The non-uniformity correction device of the embodiment of the present invention and the method for correcting the non-uniformity of an infrared detector using the device will be described in detail below with reference to the accompanying drawings.

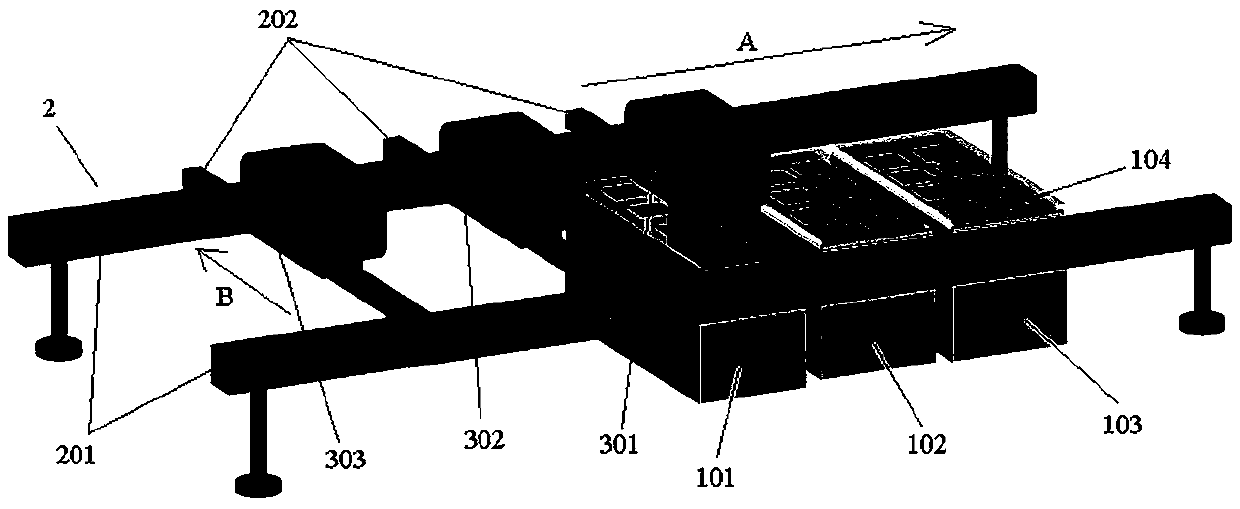

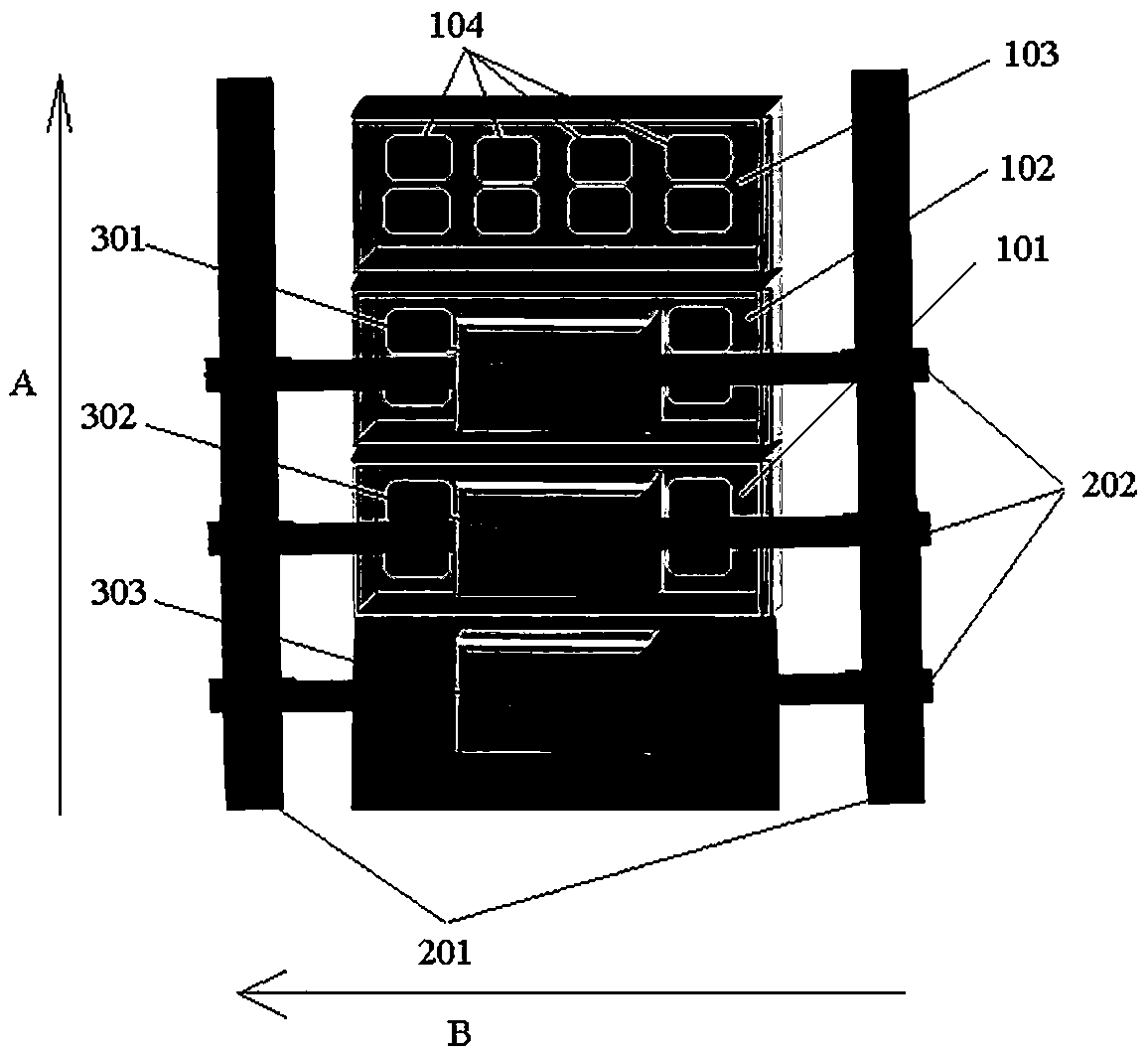

[0040] refer to figure 1 with figure 2 , in one embodiment of the present invention, a device for correcting the non-uniformity of the infrared detector may include a plurality of thermostats (for example, figure 1 with figure 2 101, 102 and 103 in), displacement motor platforms (for example, figure 1 with figure 2 2 in ) and multiple boldfaces (eg, figure 1 with figure 2 301, 302 and 303 in ).

[0041] The plurality of thermostats can be along a first direction (for example, figure 1 with figure 2 Arranged in the direction indicated by the arrow A in). Each incubator houses multiple infrared detector test setups (e.g., figure 1 with figure 2 104 in ). The plurality of infrared detector testing devices are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com