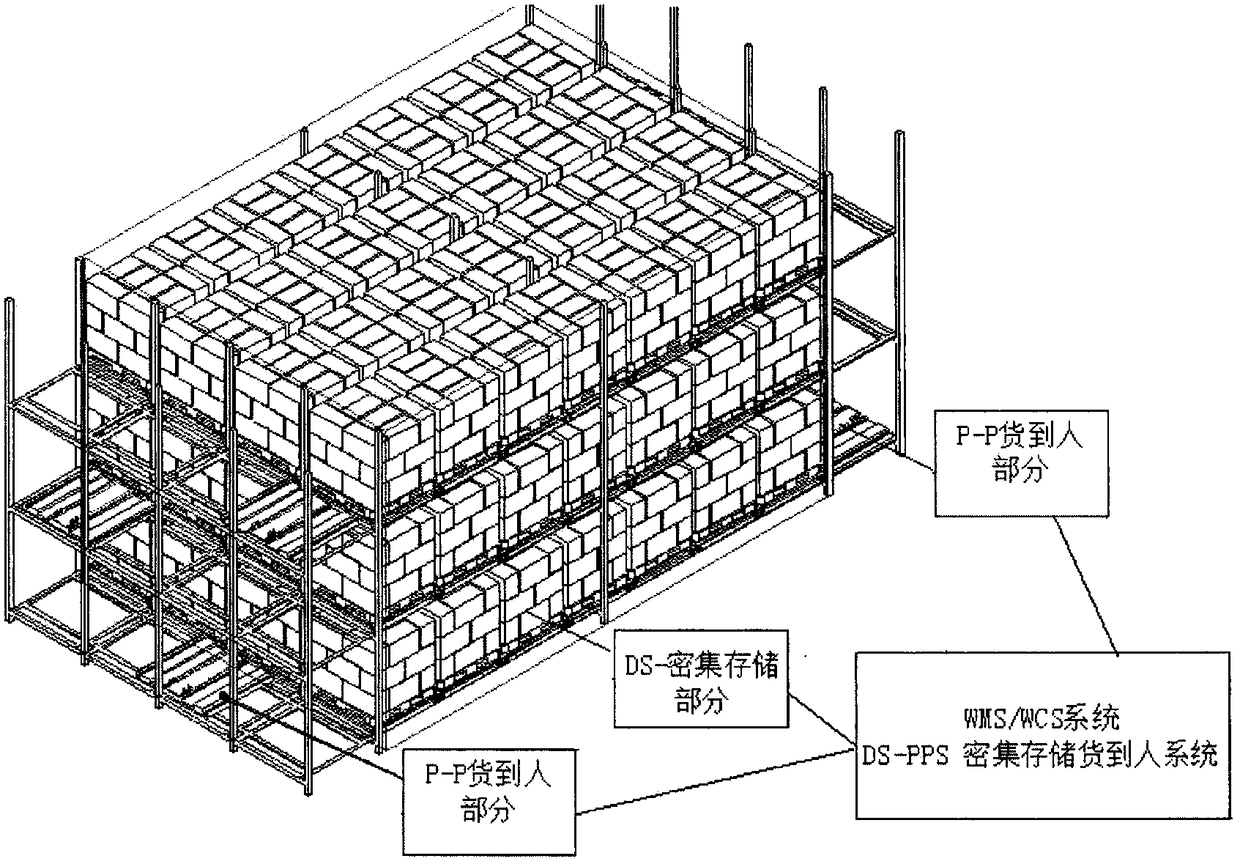

Pallet-type dense storage-pallet to people system (DS-PPS)

A DS-PPS, pallet technology, applied in the DS-PPS pallet intensive storage goods-to-person system, in the field of whole pallet cargo access, which can solve the problem of high ground storage requirements, slow access speed, and high risk of goods falling. problems, to achieve the effect of lowering the construction environment requirements, speeding up the flow of goods, and speeding up the operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] DS-PPS: (dense storage-pallet to people system) pallet-type dense storage goods-to-people system;

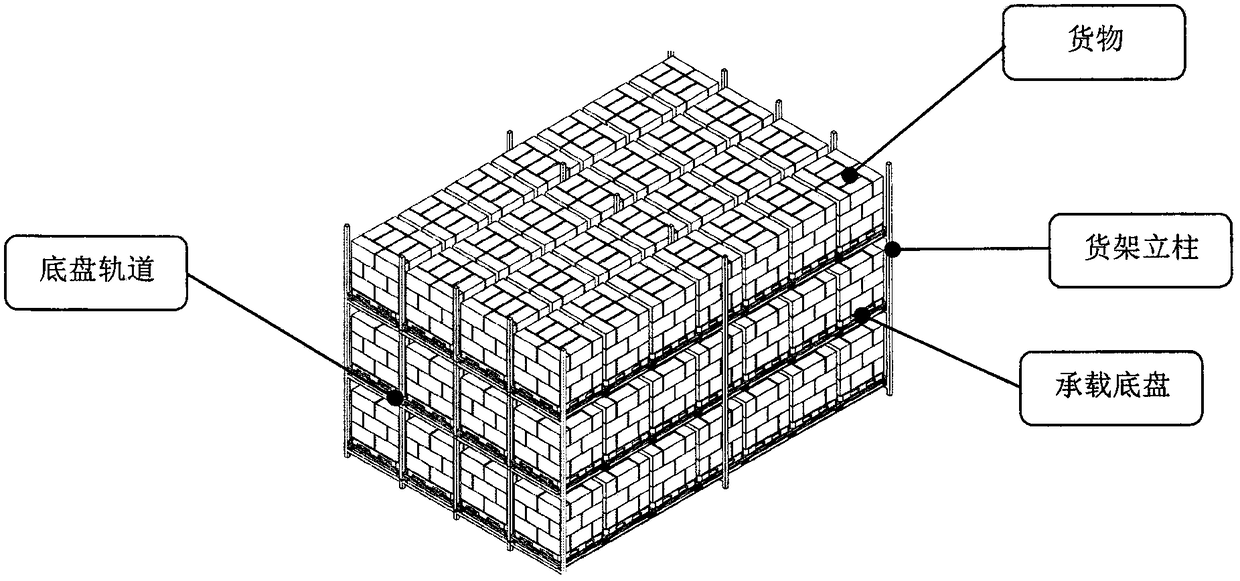

[0018] Intensive storage: The storage chassis for storing pallets are stored in the shelf one by one, forming a group, 3-4 groups form a column, and multiple columns form a partition (column division in the warehouse) and multiple partitions form a storage system .

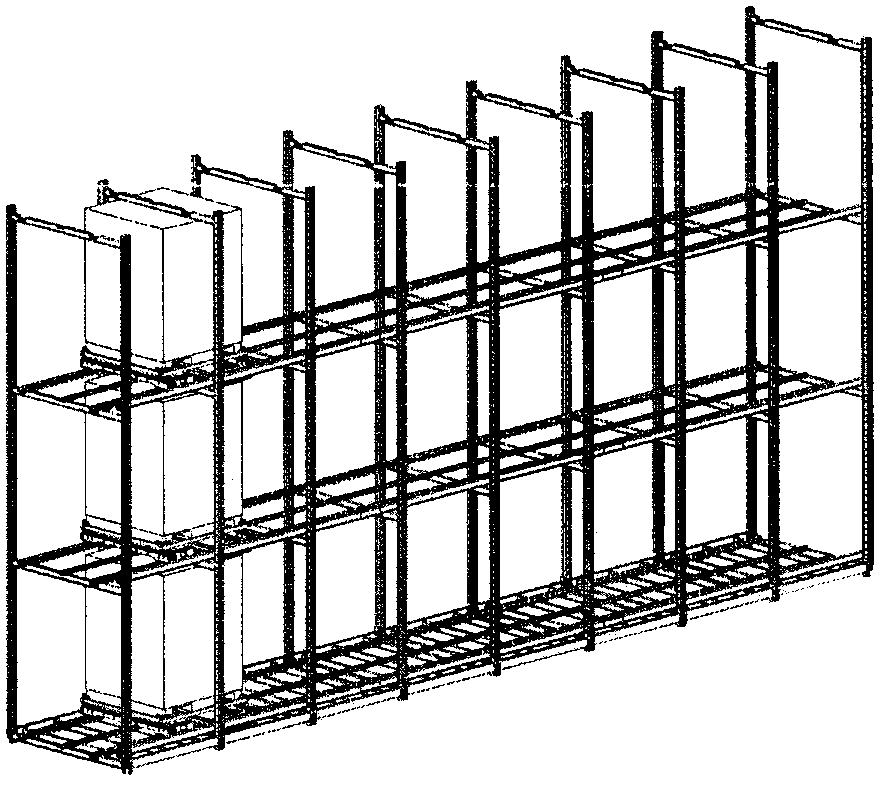

[0019] RGV robot: An access cargo robot that walks along a track.

[0020] Goods-to-person RGV track: The robot walks left and right along the track, and after picking up the goods, it takes the goods out of the storage area and sends them to the personnel.

[0021] The invention provides a DS-PPS pallet-type intensive storage goods-to-person system, including MS-warehouse management system, which manages the attributes, positions, time and quantity of goods entering and leaving the warehouse; including WCS-equipment control system, which receives the information issued by WMS Instructions to control the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com