Garbage can opening overturning and cutting-off device

A technology of a cutting device and a trash can, applied in the trash can field, can solve the problems of sticking to the outer surface of the trash bag, insufficient convenience, difficulty, etc., and achieve the effect of improving the convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

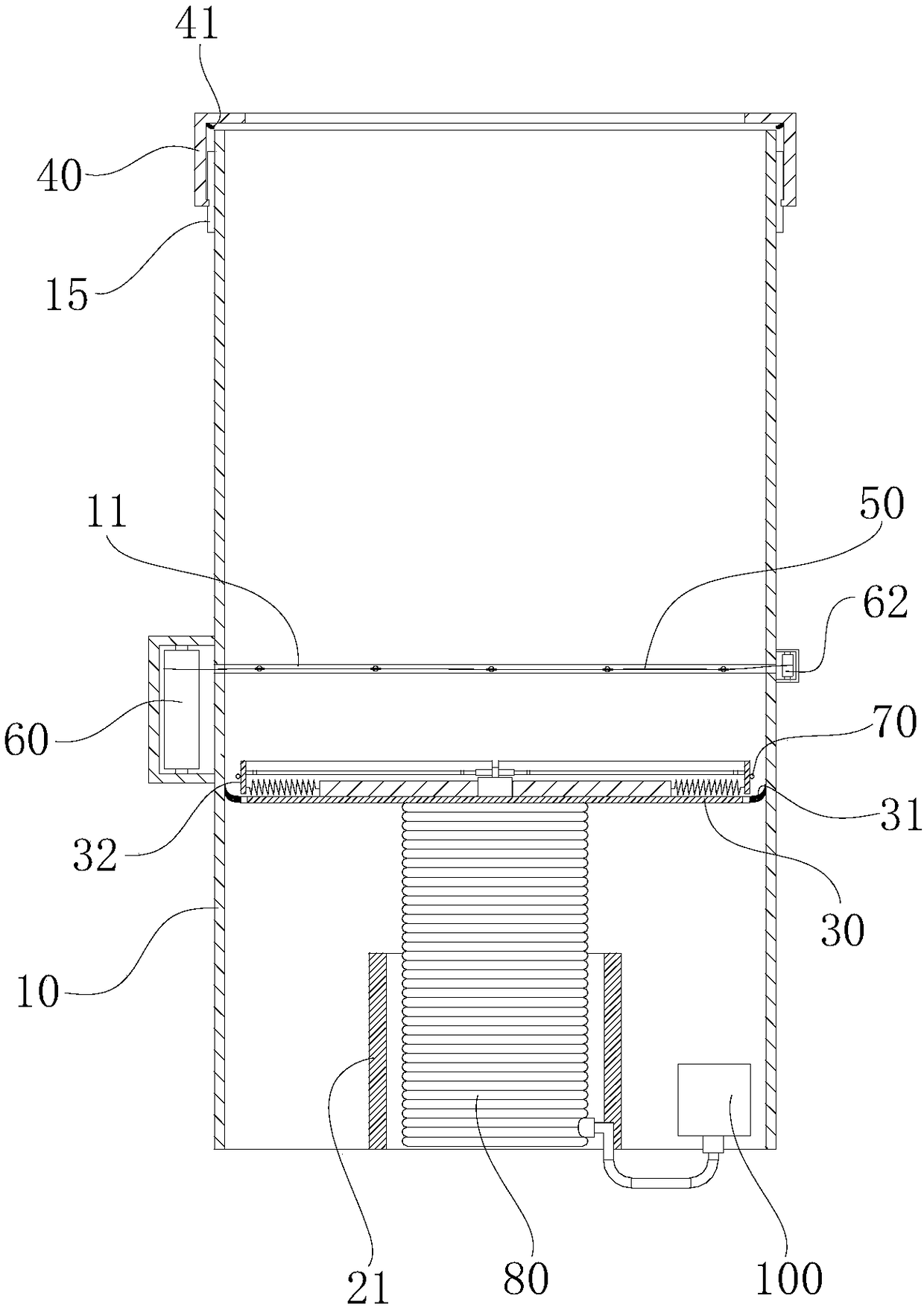

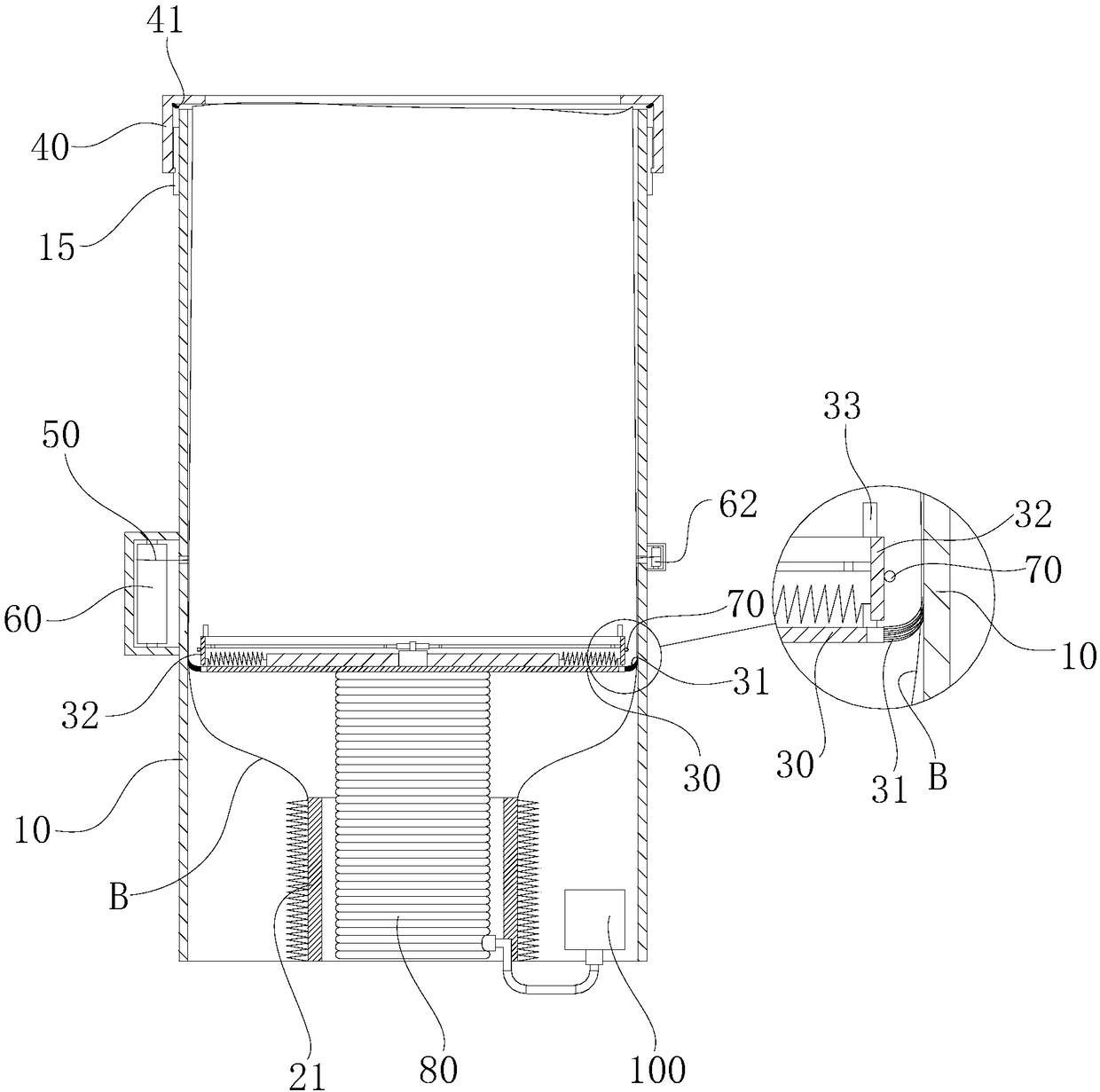

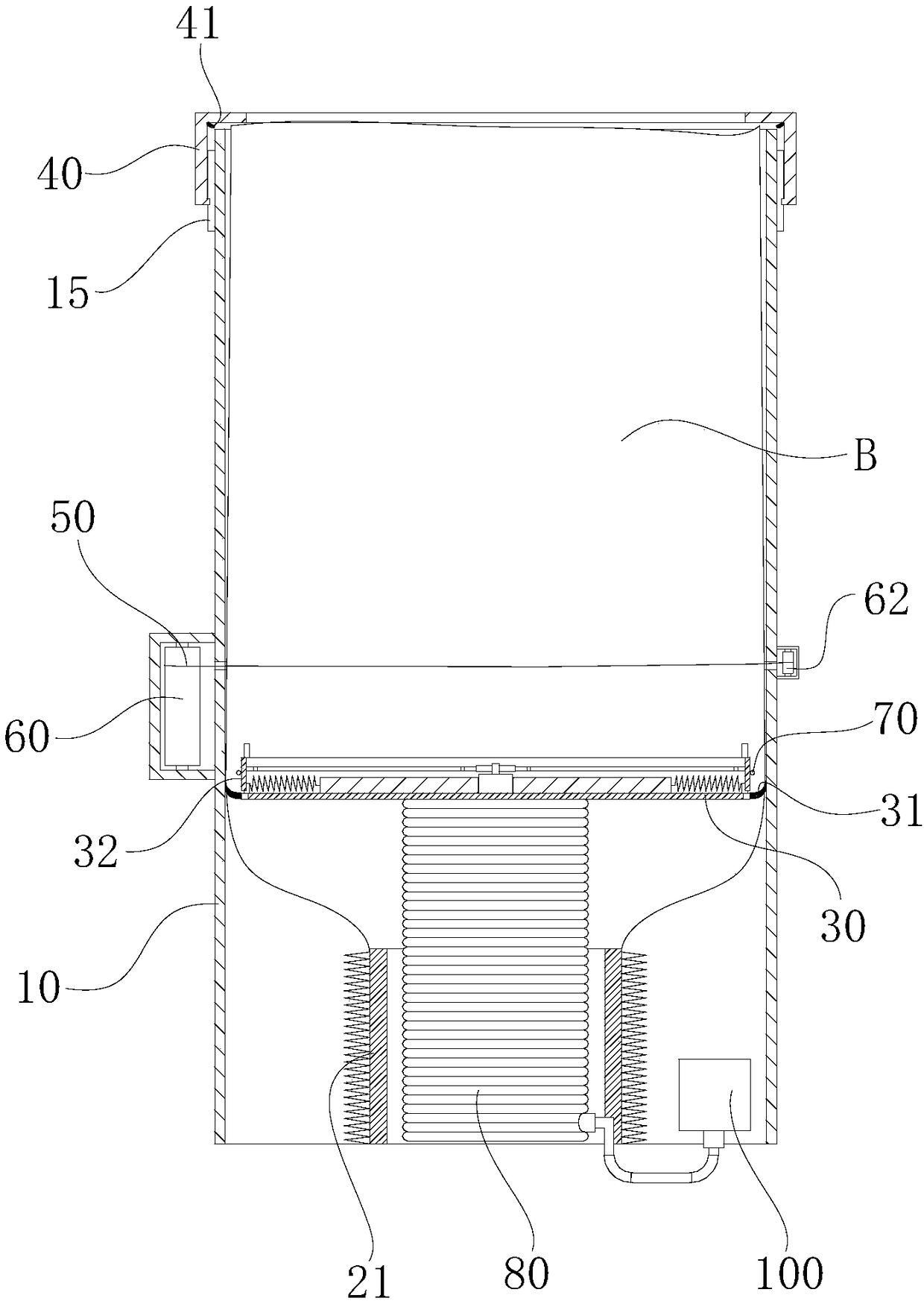

[0023] combine Figure 1 to Figure 18 , the present invention is further described:

[0024] The garbage can turning and cutting device of the present invention will be described in detail below in conjunction with the automatic packaging process of the entire garbage bag:

[0025] Before introducing the present invention, at first the garbage bag of the present invention is different from the common rolling garbage bag or the common plastic convenience bag in the prior art. On the feeding mechanism, in actual use, the barrel-shaped garbage bag is cut or sealed according to the actual use, so that the round tubular film tube set on the feeding mechanism is conveniently divided into individual plastic bags to form a single garbage bag. The specific application of this type of raw material circular tube film in the trash can is described in detail below.

[0026] combine Figure 1 to Figure 6 As shown, the trash can includes a trash can body 10, a feeding mechanism for provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com