Auxilary device for casting mould

An auxiliary device and casting mold technology, applied in the field of casting, can solve the problems of high defect rate and heavy repair workload, etc., and achieve the effects of improving yield, strengthening feeding and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

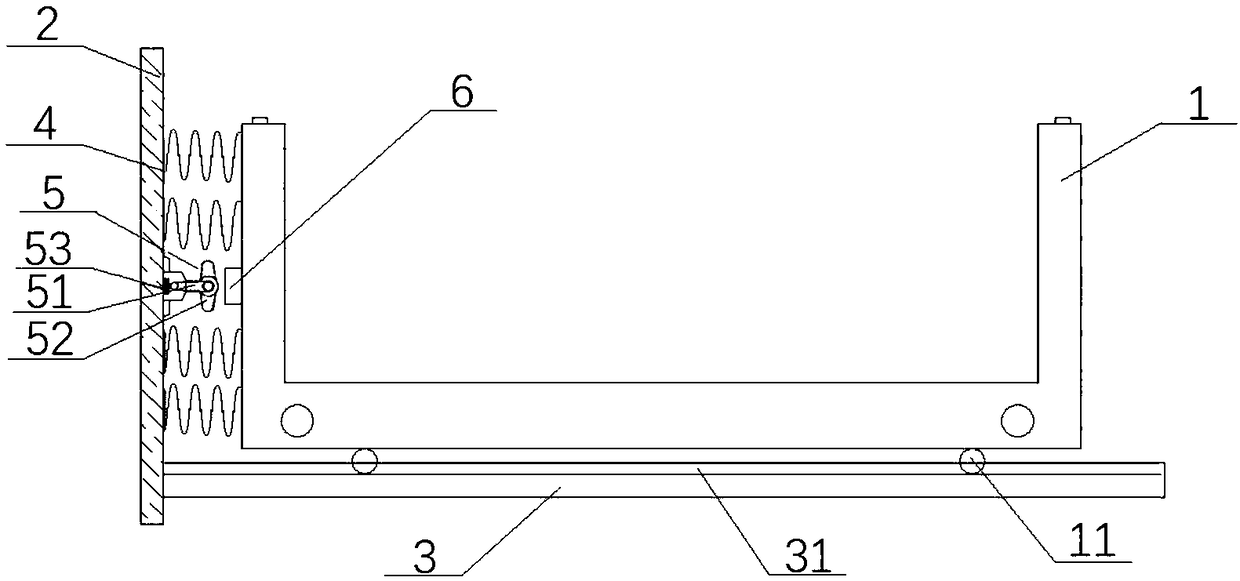

[0028] like Figure 1 ~ Figure 2 The auxiliary device for casting mold shown includes a box body 1 for placing a casting box, a baffle plate 2 and a bottom plate 3, the bottom plate 3 is provided with a chute 31, and the bottom of the box body 1 is provided with a pulley 11 , the pulley 11 slides in the chute 31 so that the box body 1 is slidably connected with the bottom plate 3;

[0029] The baffle plate 2 is arranged on one side of the bottom plate 3, and the baffle plate 2 protrudes a vibrating spring 4 and a telescopic member 5 laterally toward the box body 1, and the other end of the vibrating spring 4 is installed on the box body 1, the telescopic member 5 abuts against the box body 1 intermittently, and the minimum length of the vibrating spring 4 when compressed > the minimum length of the telescopic member 5 when contracted.

[0030] The telescopic member 5 includes a mount 51 arranged on the baffle 2 , a cam 52 and a drive motor 53 arranged on the mount 51 ;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com