A capacitor nailing and winding device

A winding device and capacitor technology, used in capacitors, capacitor manufacturing, winding capacitor machines, etc., can solve problems such as unsmooth needle feeding, scratches on guide needles, etc., and achieve the effect of solving random needles, stable speed and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and technical effect of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

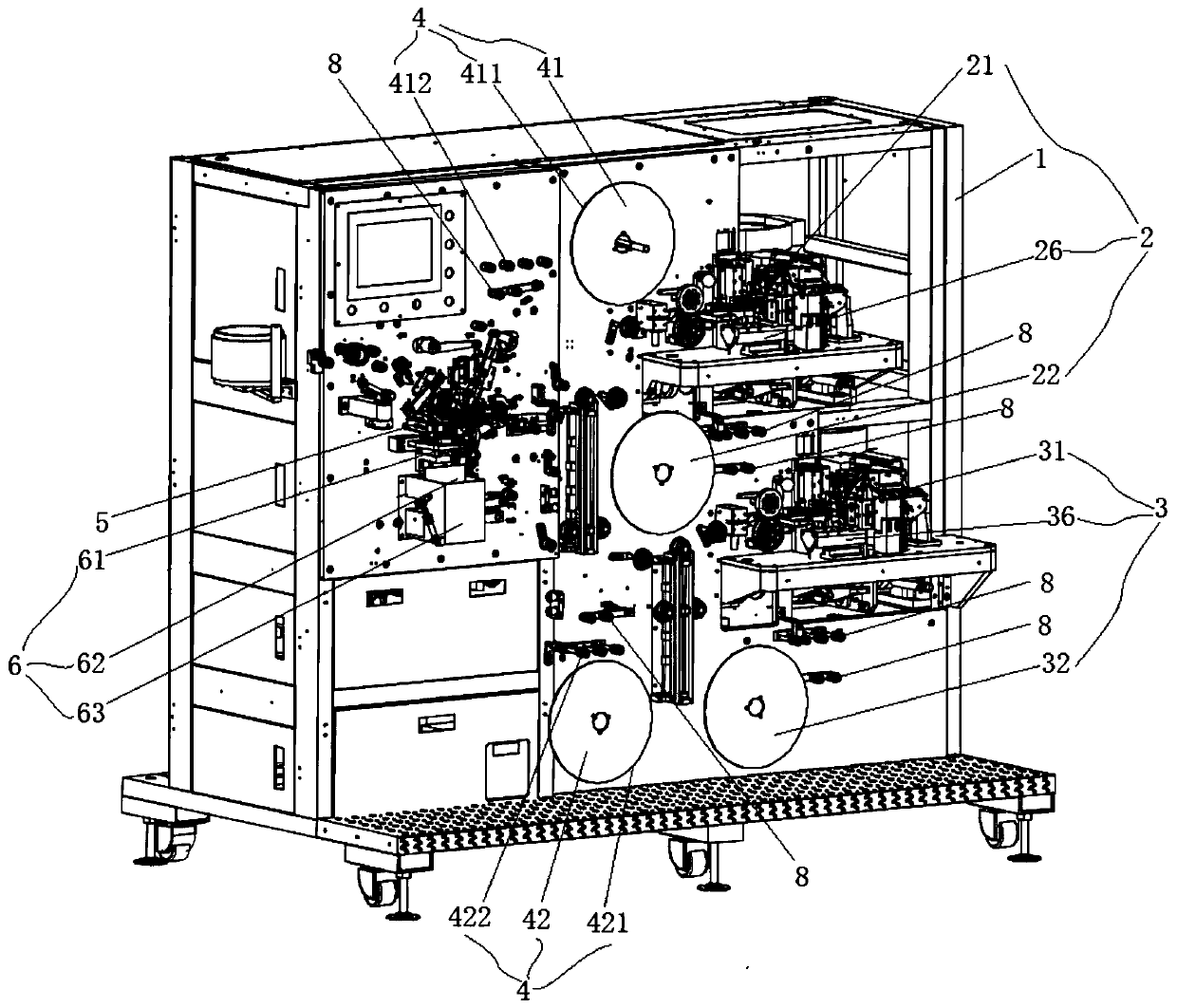

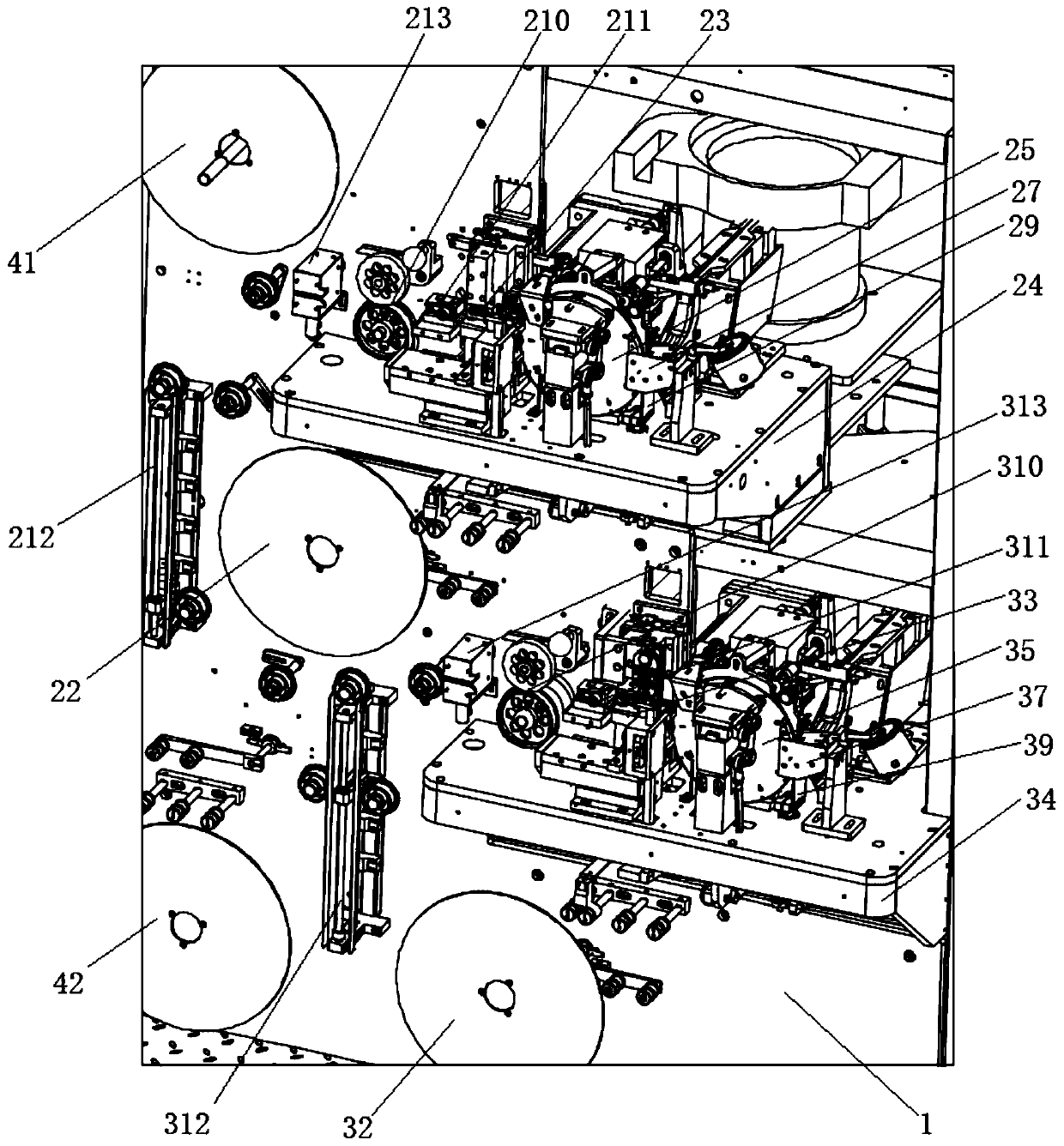

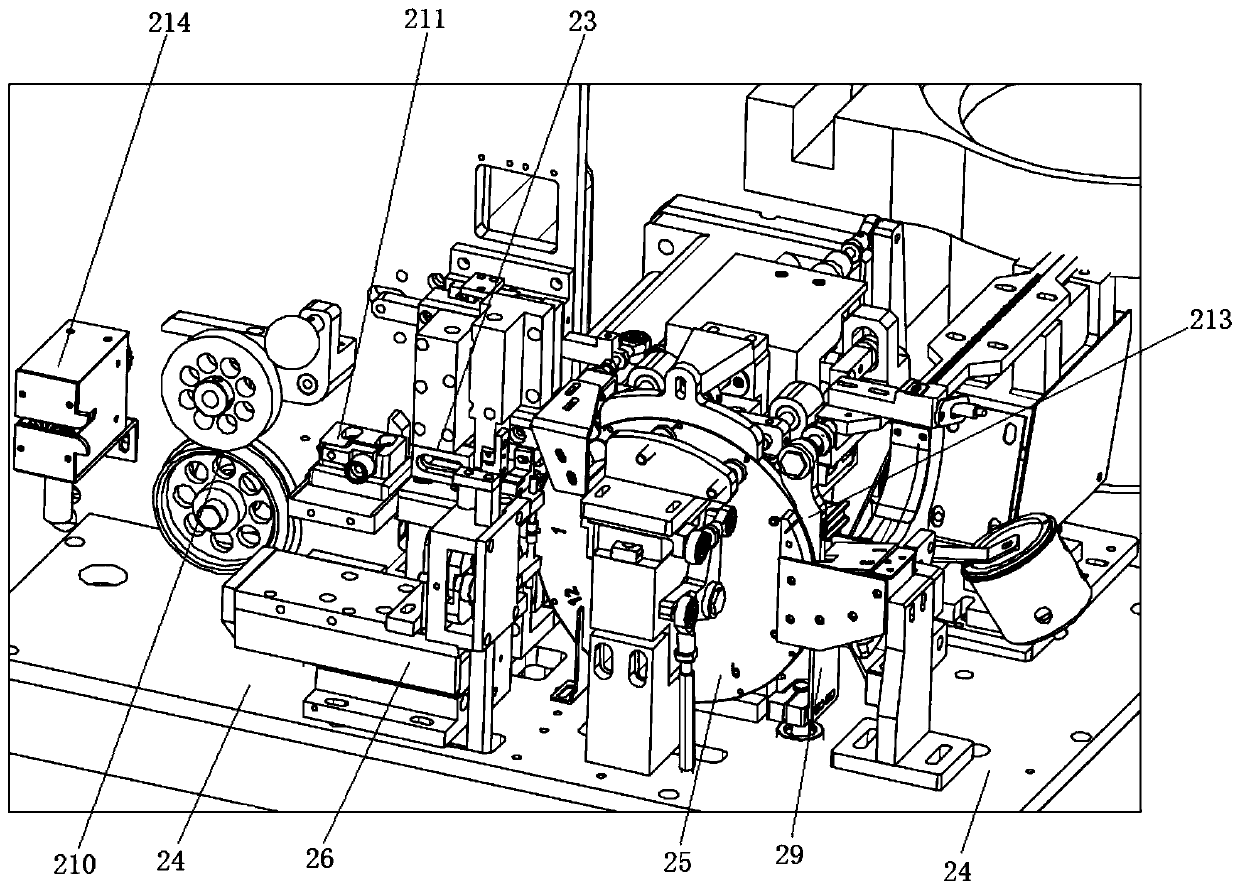

[0033] Such as Figure 1-2 As shown, one embodiment of the present invention provides a capacitor nailing and winding device, the device includes a device body 1, and the device body 1 is provided with a positive electrode nailing machine 2, a negative electrode nailing machine 3, and an electrolytic paper unwinding machine 4 and winder 5:

[0034] In this embodiment, the positive electrode stitching machine 2 is arranged on the upper right side of the device body 1, including a first needle feeding mechanism 21, a positive electrode foil disc 22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com