Based on three-tier tio 2 Dye Cells with Composite Thin Films

A composite thin film and dye cell technology, applied in the field of dye-sensitized solar cells, can solve the problems that cannot meet the requirements of industrialization, and achieve the effect of facilitating adsorption and reducing annihilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

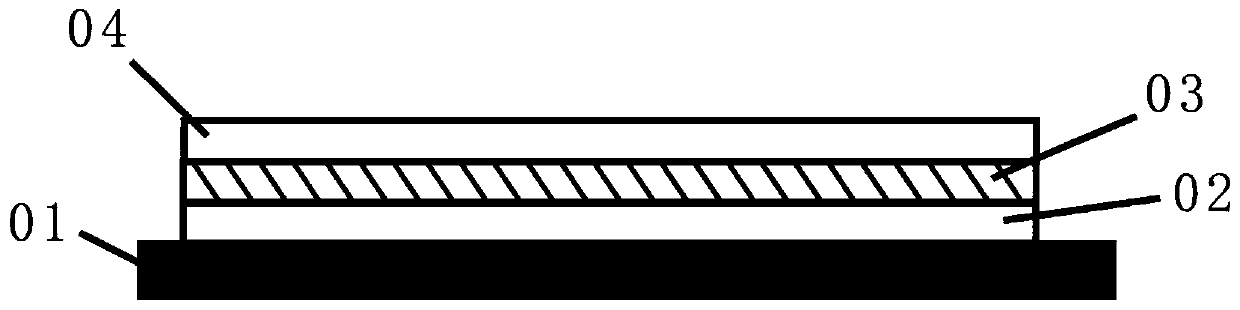

[0033] In this embodiment, a dye-sensitized solar cell includes a photoanode, a counter electrode and an electrolyte, wherein the photoanode and the counter electrode are arranged opposite to each other with a liquid electrolyte in between.

[0034] The photoanode includes a FTO conductive substrate, on the surface of the FTO conductive substrate is provided with TiO 2 composite film; the TiO 2 The composite film is formed by screen-printing TiO on the surface of the FTO conductive substrate 2 composite slurry, thereby forming the TiO 2 Composite film.

[0035] Specifically, the TiO 2 The composite film is a three-layer structure, from the photoanode FTO substrate to the opposite electrode direction, the TiO 2 Composite thin films sequentially include TiO 2 Underlayer composite film, TiO 2 Middle layer composite film, TiO 2 Upper composite film.

[0036] The TiO 2 The upper composite film contains BaTiO 3 / MoS 2 / TiO 2 nanosheet heterostructure, in which the TiO 2...

Embodiment 2

[0070] In this embodiment, a dye-sensitized solar cell includes a photoanode, a counter electrode and an electrolyte, wherein the photoanode and the counter electrode are arranged opposite to each other with a liquid electrolyte in between.

[0071] The photoanode includes a FTO conductive substrate, on the surface of the FTO conductive substrate is provided with TiO 2 composite film; the TiO 2 The composite film is formed by screen-printing TiO on the surface of the FTO conductive substrate 2 composite slurry, thereby forming the TiO 2 Composite film.

[0072] Specifically, the TiO 2 The composite film is set up as a double-layer structure, from the photoanode FTO substrate to the direction of the opposite electrode, the TiO 2 Composite thin films sequentially include TiO 2 Underlayer composite film, TiO 2 Upper composite film.

[0073] The TiO 2 The upper composite film contains BaTiO 3 / MoS 2 / TiO 2 nanosheet heterostructure, in which the TiO 2 For nanosheets, B...

Embodiment 3

[0083] In this embodiment, a dye-sensitized solar cell includes a photoanode, a counter electrode and an electrolyte, wherein the photoanode and the counter electrode are arranged opposite to each other with a liquid electrolyte in between.

[0084] The photoanode includes a FTO conductive substrate, on the surface of the FTO conductive substrate is provided with TiO 2 composite film; the TiO 2 The composite film is formed by screen-printing TiO on the surface of the FTO conductive substrate 2 composite slurry, thereby forming the TiO 2 Composite film.

[0085] Specifically, the TiO 2 The composite film is set up as a double-layer structure, from the photoanode FTO substrate to the direction of the opposite electrode, the TiO 2 Composite thin films sequentially include TiO 2 Underlayer composite film, TiO 2 Middle layer composite film, TiO 2 Upper composite film.

[0086] The TiO 2 The upper composite film contains BaTiO 3 / MoS 2 / TiO 2 nanosheet heterostructure, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com