Carbon-fiber-reinforced composite fireproof plate

A technology for enhancing composite and fireproof boards, applied in fire prevention, construction, building components, etc., can solve the problems of inconvenient noise transmission, inconvenient substrate damage, inconvenience in the strength of fireproof boards, etc., to reduce noise transmission, scientific and rational structure, and use Safe and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

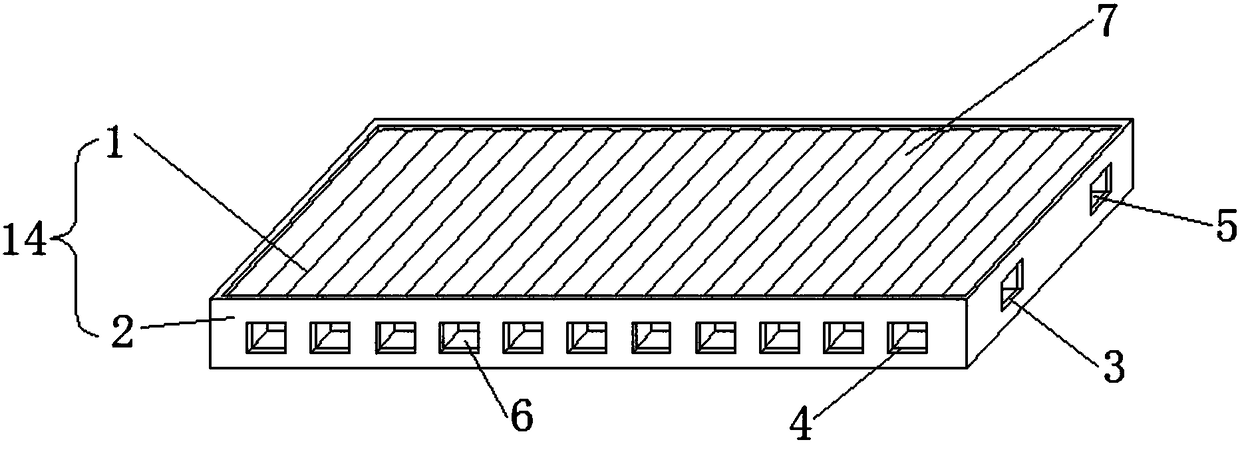

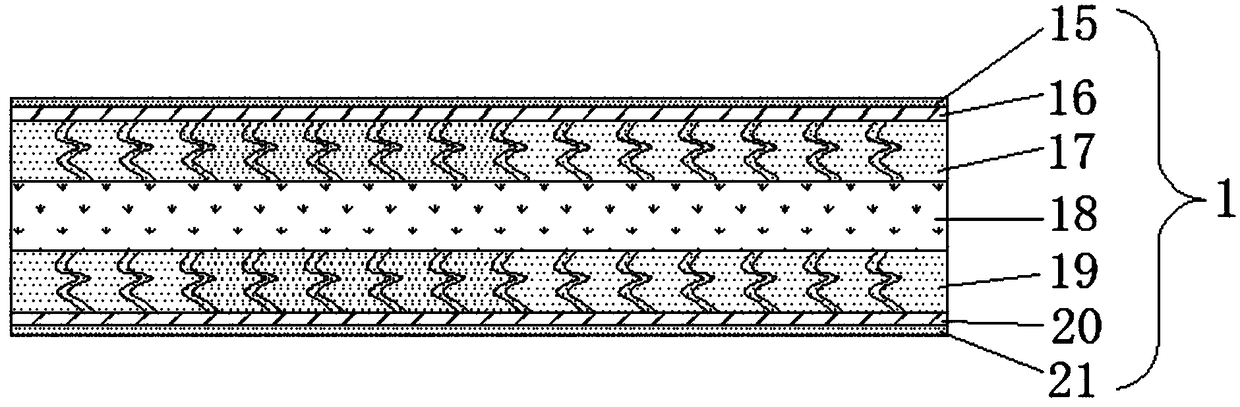

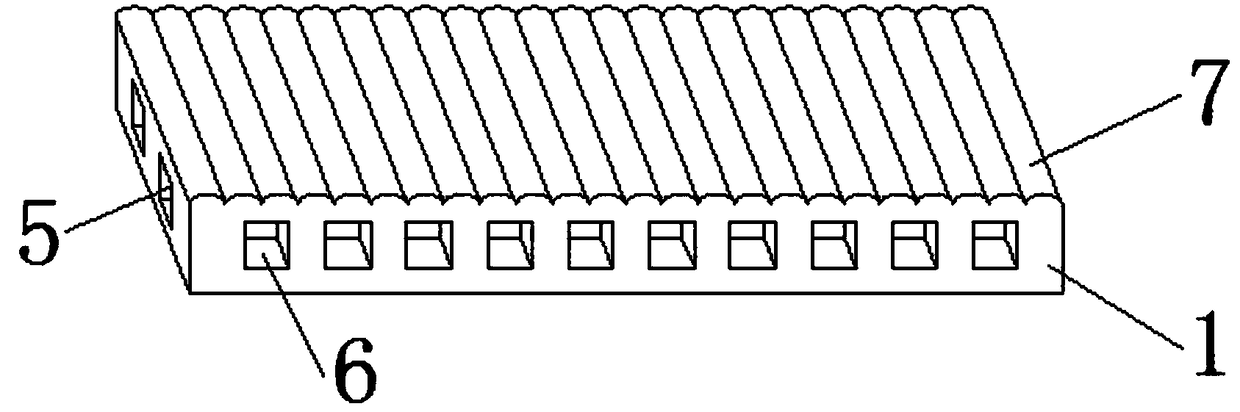

[0021] Example: such as Figure 1-6 As shown, the present invention provides a carbon fiber reinforced composite fireproof board, including a substrate 1, an aluminum alloy shell 2, a first through hole 3, a second through hole 4, a first groove 5, a second groove 6, and a curved plate 7. First insert 8, second insert 9, bump 10, card slot 11, second composite fireproof board 12, third composite fireproof board 13, first composite fireproof board 14, first surface fireproof skin veneer layer 15, the first carbon fiber reinforced layer 16, the first sound-absorbing board 17, the PVC foam core material layer 18, the second sound-absorbing board 19, the second carbon fiber reinforced layer 20 and the second surface fire-resistant skin veneer layer 21, the first composite The fireproof board 14 includes a base plate 1 and an aluminum alloy shell 2, the aluminum alloy shell 2 is arranged on the outside of the base plate 1, and the outermost layer of the base plate 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com