Spreading device for pouring type compound pavement

A composite pavement and spreading device technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of low production efficiency, time-consuming and labor-consuming, and affect the overall quality of the poured composite pavement, so as to achieve convenient operation and reduce flatness Requirements, the effect of shortening the spreading time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

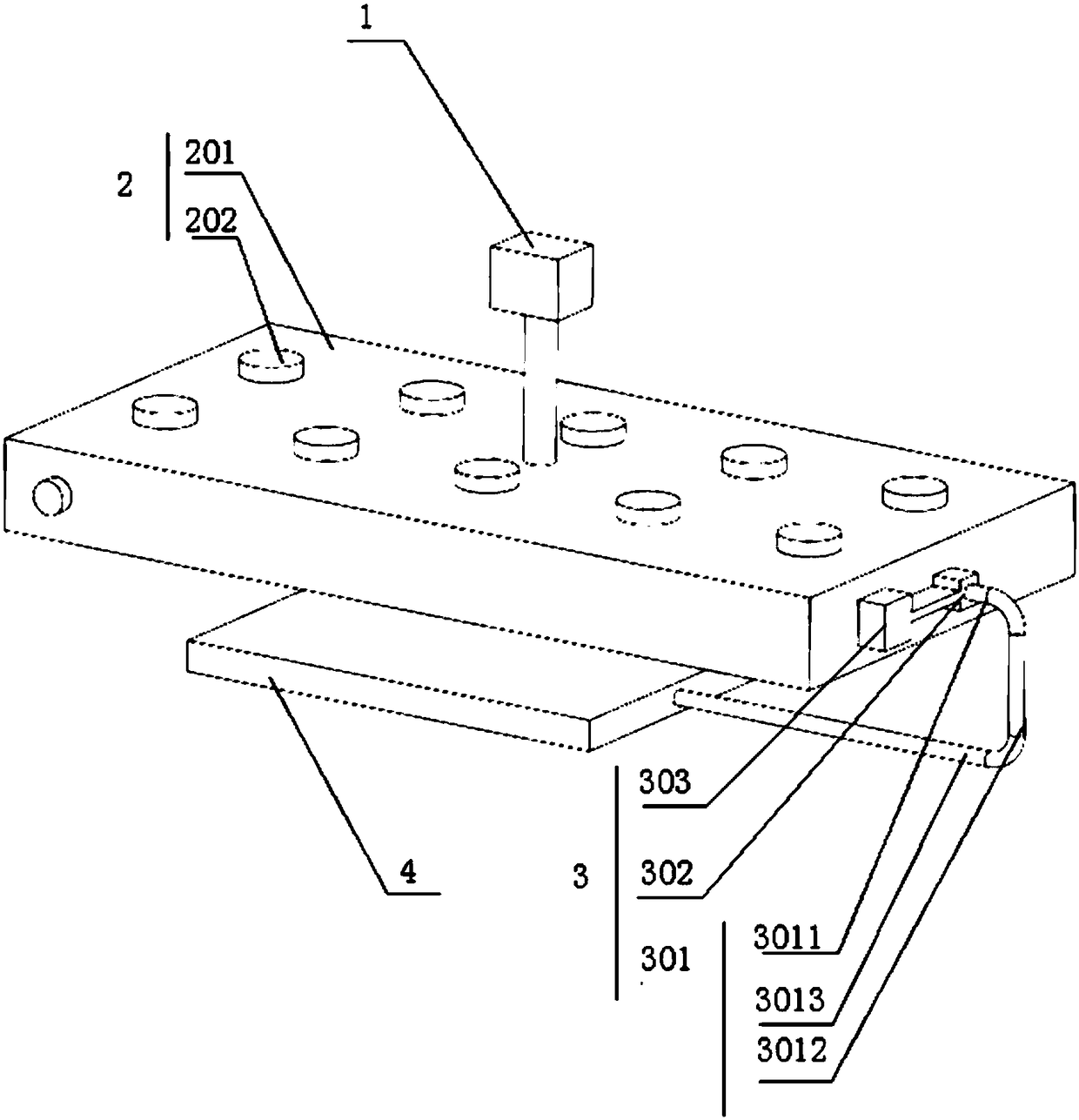

[0033] Specifically, such as figure 1 As shown, a spreading device for pouring composite pavement of the present invention includes a pressing unit, a spreading unit and a control unit (not shown in the figure);

[0034] The pressing unit includes a first drive assembly 1 and a pressing plate unit 2;

[0035] The first driving assembly 1 is preferably a driving cylinder, the output shaft of which is connected to the platen unit 2, and receives the control signal from the control unit to drive the platen unit 2 to move up and down in the vertical direction, that is, to realize the pressing of the materials spread on the road surface. peaceful compaction;

[0036] The pressing plate unit 2 includes a pressing plate 201 and a plurality of vibrators 202. The pressing plate 201 is arranged parallel to the ground. In order to reduce material costs, the pressing plate 201 can be set as a hollow structure. Since the road surface is mostly a rectangular structure, this The pressing p...

Embodiment 2

[0046] Based on Embodiment 1, the difference between this embodiment and Embodiment 1 is that in the embodiment of the present invention, several distance measuring sensors (not shown in the figure) are also included, and the several distance measuring sensors are along the extending direction of the pressing plate. Installed at equal intervals on the outside of the side wall of the pressure plate (the side wall is opposite to the side wall provided with the second drive assembly), and located on the same horizontal plane, the output ends of each distance measuring sensor are connected to the control unit;

[0047] After finishing the first spreading and pressing, each ranging sensor measures the distance between the platen and the spreading material on the ground. After receiving all the distances, the control unit judges the monitoring point that needs to continue spreading, and controls the The second driving component drives the spreader to move to the monitoring point wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com