Liquid food packaging sterilization device

A disinfection device and liquid food technology, applied in packaging, packaging protection, packaging sterilization, etc., can solve problems such as infection of bacteria, secondary pollution, health hazards of eaters, etc., to achieve the effect of ensuring food safety and convenient liquid filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

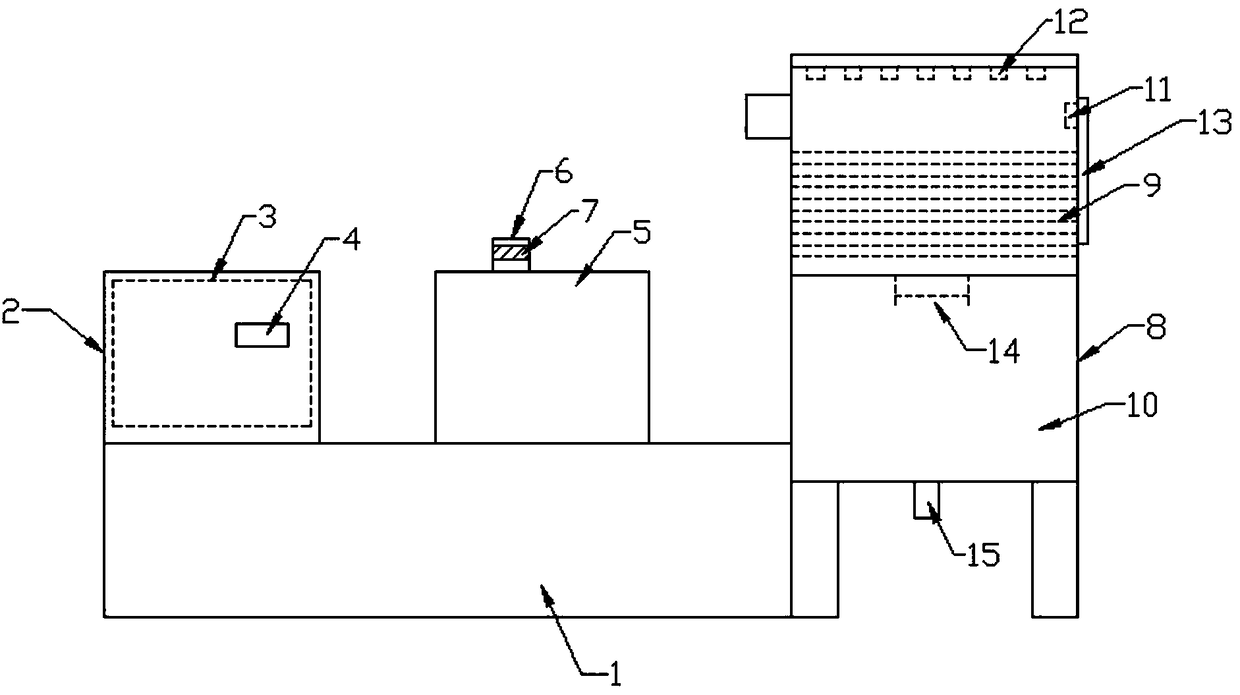

[0016] Example: such as figure 1 As shown, a liquid food packaging disinfection device of the present invention comprises a high-temperature sterilization chamber 2, a cooling chamber 5 and a liquid food case 8, the high-temperature sterilization chamber 2 and the cooling chamber 5 are all fixed above the conveyor belt 1, and the inner wall of the high-temperature sterilization chamber 2 An electric heating plate 3 is fixed on the top, and a time display 4 is installed on the outside of the high-temperature disinfection chamber 2, and the time display 4 is electrically connected to the electric heating plate 3 through a data wire; the top of the cooling chamber 5 is fixed with an air inlet pipe 6, and the air inlet pipe 6 A fan 7 is installed inside, and both sides of the cooling chamber 5 close to and away from the high-temperature disinfection box 2 are open; the liquid food box 8 is fixed on the end of the conveyor belt 1, and the liquid food box 8 is separated into a steril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com