Resistance ceramic white bar forming production processing technology

A technology of resistive ceramics and processing technology, which is applied in the field of ceramic processing, can solve the problems of easy air bubbles in ceramic rods, difficulty in demoulding, and high defective rate of ceramic white rods, so as to avoid air mixing inside, avoid breakage, and reduce breakage rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

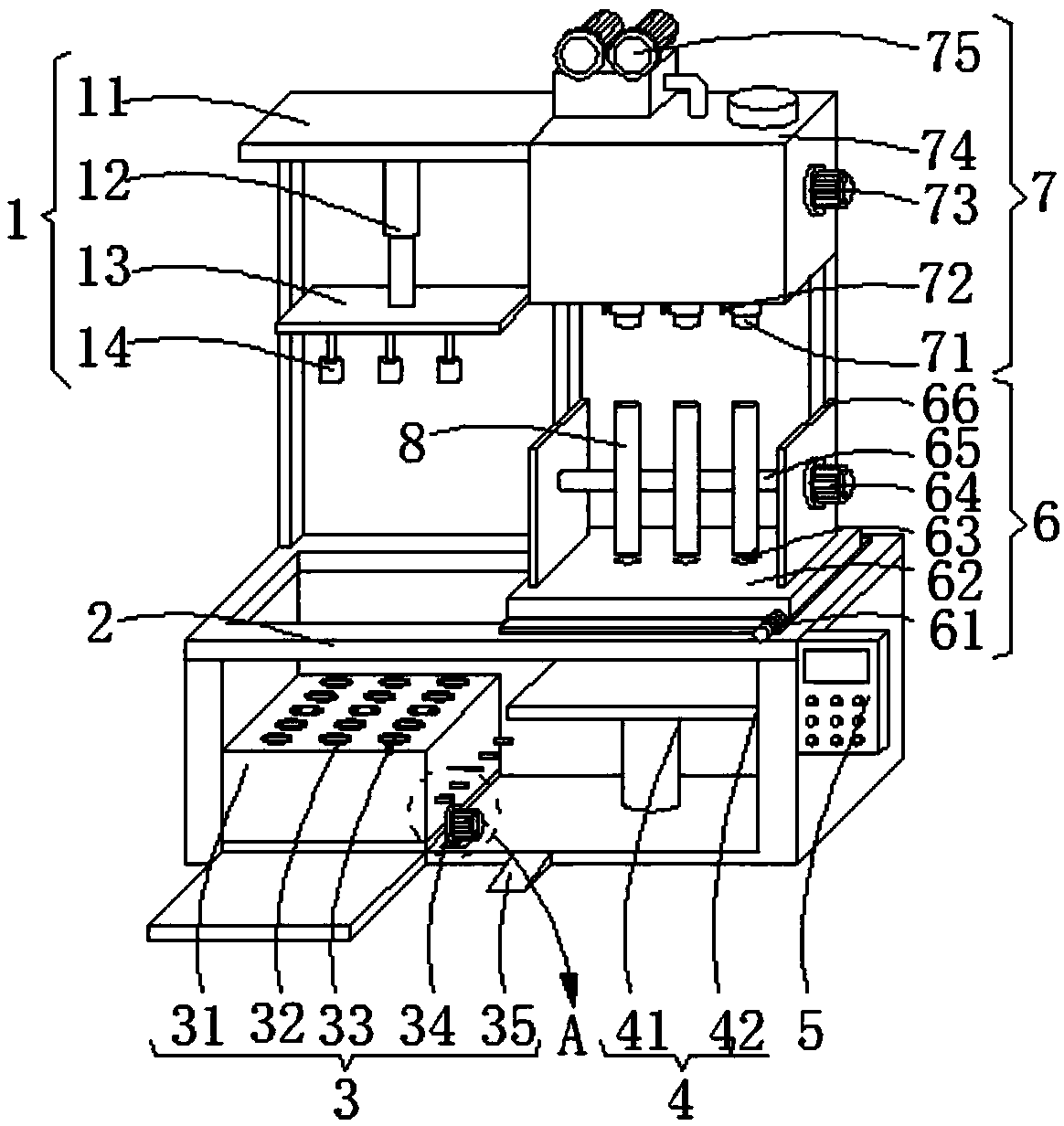

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0033] like figure 1 Shown, a kind of resistance ceramic white rod forming production and processing technique described in the present invention, this production and processing technique comprises the following steps:

[0034] S1, preparing raw materials;

[0035] S2, mixing the raw materials in S1;

[0036] S3, adding the mixed raw materials in S2 to the white rod forming equipment;

[0037] S4, putting the ceramic white rod formed in S3 into a kiln for firing;

[0038] S5, cooling the ceramic white rod after firing and molding in S4, and putting it into a sulfuric acid solution to remove the stains on the surface of the ceramic white rod;

[0039] After S6 and S5 are over, put the ceramic white rods into the dust-free warehouse for storage;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com