Flotation system and process for refractory minerals

A kind of mineral flotation, difficult to select technology, applied in the direction of flotation, solid separation, etc., can solve the problem of waste of collector pulp mixing effect, unable to achieve synchronization, complex process, etc., to ensure the pulp mixing effect and simplify the flotation process Process, the effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

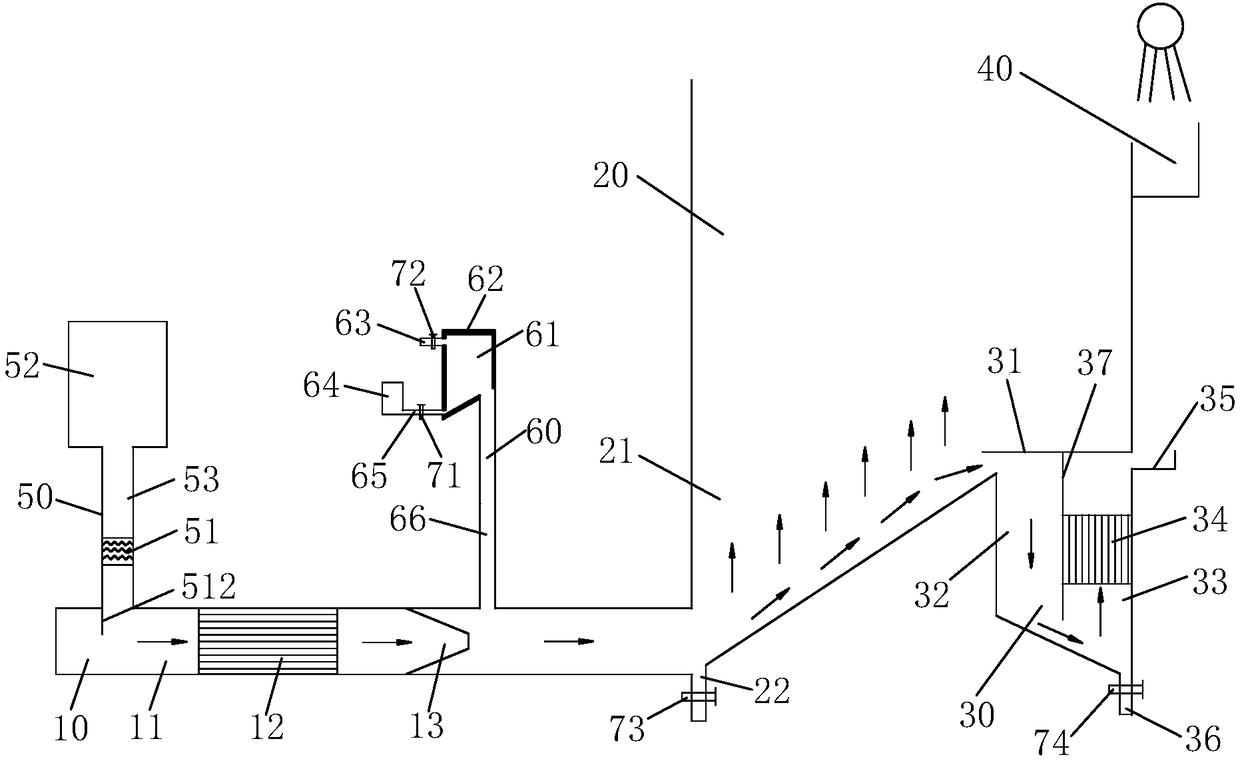

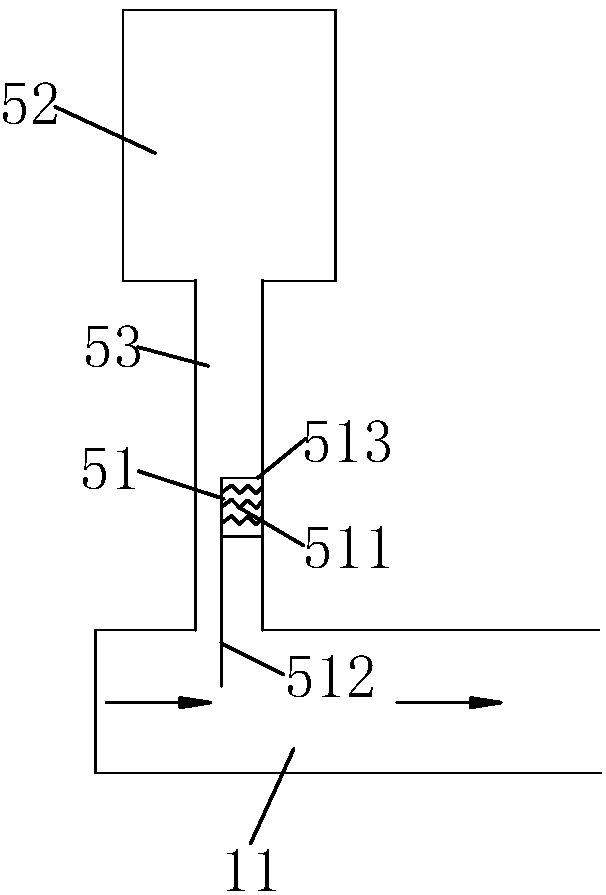

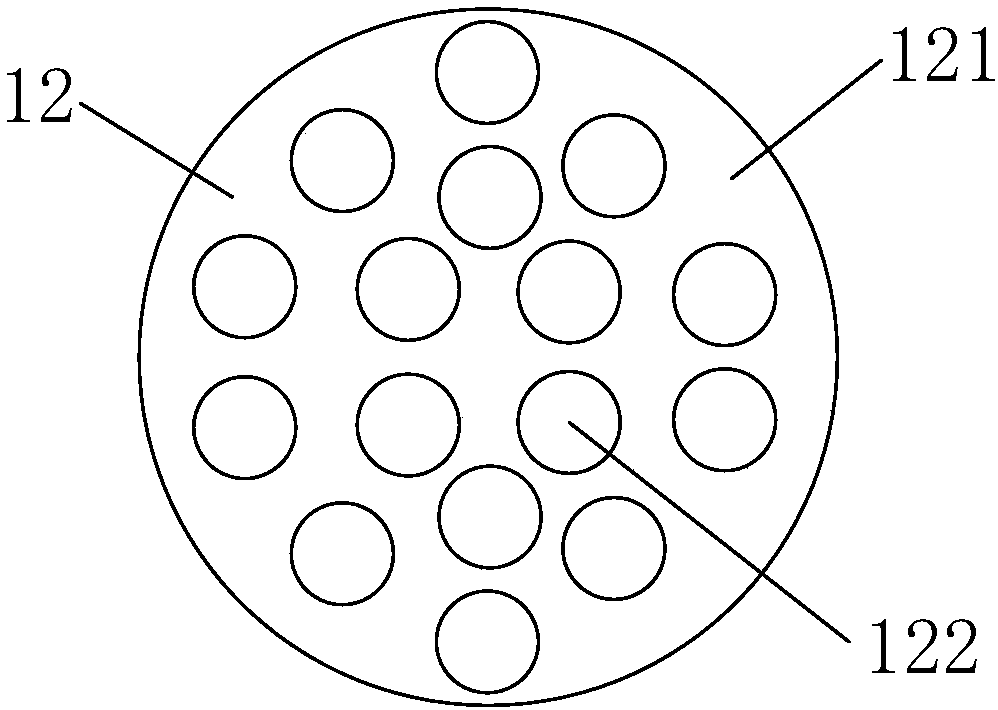

[0048] like figure 1 , 2 As shown, a kind of refractory mineral flotation system comprises a feeding mechanism 10, a flotation mechanism 20 communicated with the feeding mechanism 10, a tailings collection mechanism 30 communicated with the flotation mechanism 20, and the The concentrate collection mechanism 40 connected to the flotation mechanism 20, the feeding mechanism 10 includes a feeding transportation pipe 11 communicated with the feeding pump and a collector fixed in the feeding transportation pipe 11 for fully mixing and the slurry mixing module 12 of the ore pulp; the system also includes a collector dosing mechanism 50 communicated with the feeding transport pipe 11, and the collector dosing mechanism 50 is located between the feeding port of the feeding mechanism 10 and the adjusting Between the slurry modules 12, the collector dosing mechanism 50 is provided with a collector dosing regulator 51 for changing the dosing amount, and the adjustment amount of the col...

Embodiment 2

[0060] The flotation process of the described a kind of refractory mineral flotation system comprises the following steps:

[0061] S1, turn on the heating device 62 to preheat the foaming agent vaporization box 61;

[0062] S2. Turn on the feeding pump to make the ore slurry enter the feeding transportation pipe 11, and then open the first control valve 71 and the second control valve 72 to start working;

[0063] S3, the flotation concentrate is collected through the overflow of the concentrate collection mechanism 40 and enters the next process through the pipeline, and the bottom flow of the flotation tailings with coarse particles and low ash content enters the secondary flotation operation through the tailings discharge pipe 36, Flotation tailings high-ash fine particles overflow through the overflow weir 35 and enter the concentration operation;

[0064] S4, finish the work, first stop the feed pump, then close the first control valve 71, the second control valve 72 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com