T-shaped automatic nest box

An egg box, automatic technology, applied in the application, poultry industry, poultry cage or house, etc., can solve the problems of difficult disassembly and maintenance, low space utilization, environmental pollution, etc., and achieve easy installation, disassembly and maintenance, and space utilization. The effect of large and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

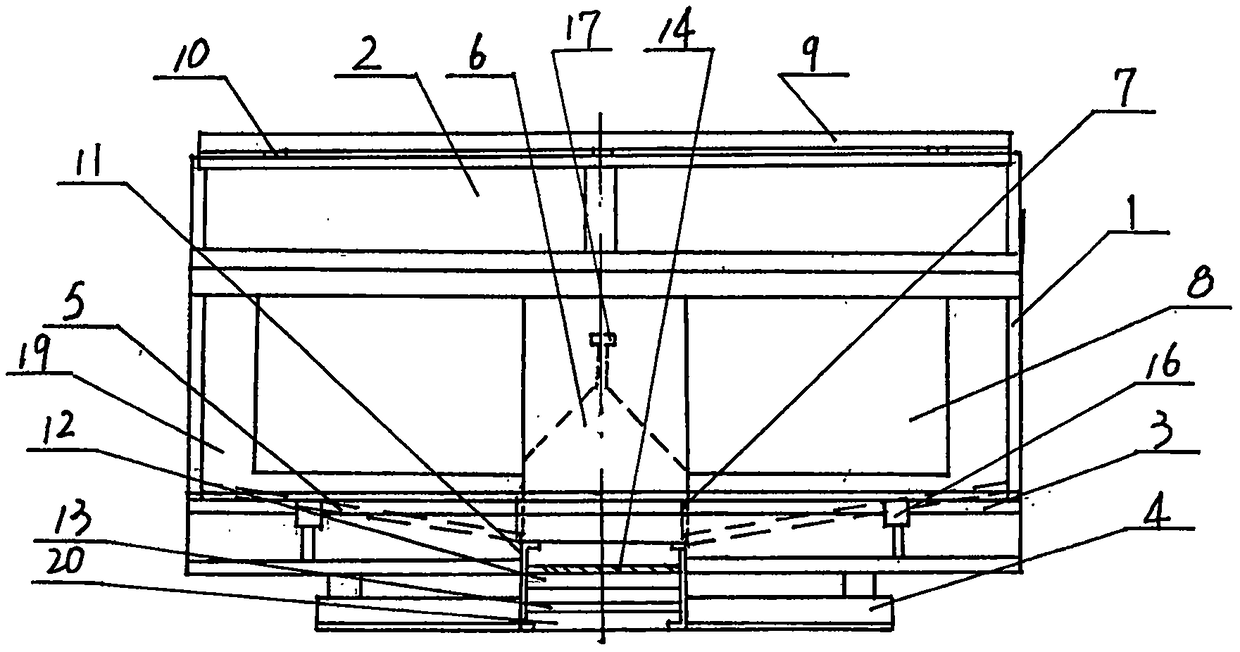

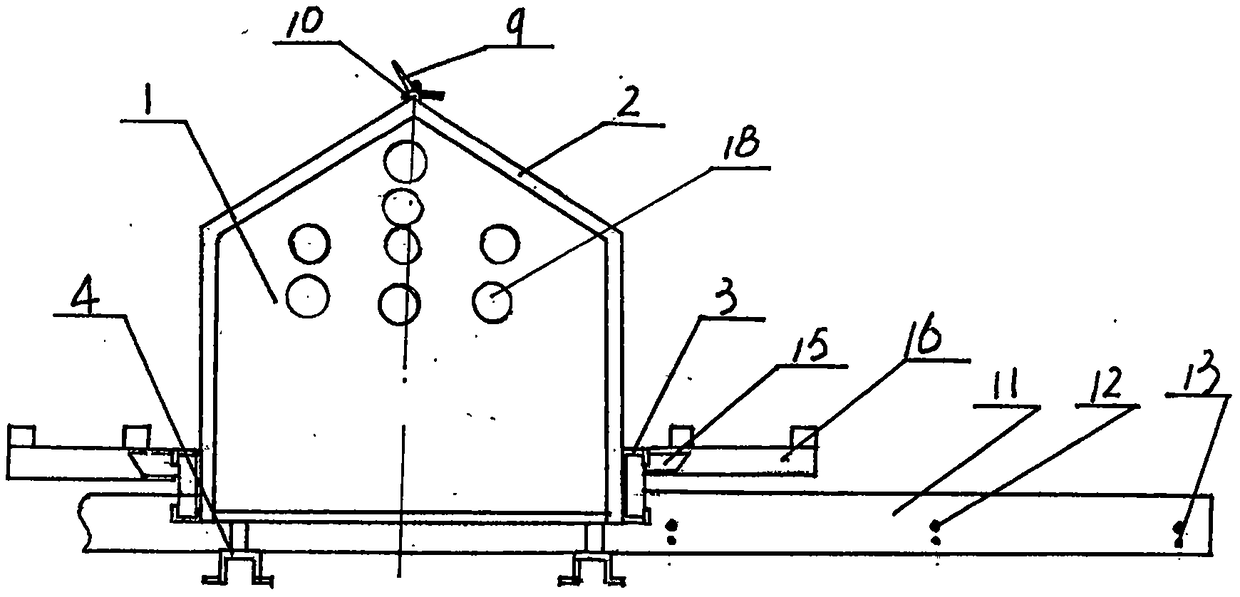

[0008] Such as figure 1 , figure 2 As shown, the inclined top 2 of a T-shaped automatic egg-laying box is fixedly arranged at the upper end of the egg-laying box 1. The egg-laying box 1 is divided into a left and right double-row egg-laying room 19 by an egg channel cover 6 and a partition 17 , The partition plate 17 is fixedly arranged on the upper end of the egg lane trough cover 6, the C-shaped channel steel 3 is fixedly arranged on the front and rear ends of the lower part of the egg-laying box 1, the positioning frame 15 is movably arranged in the slot at both ends of the C-channel steel 3, and the movable station The plate 16 is movably inserted on the positioning frame 15 and is flush with the lower end of the entrance of the laying room 19 of the laying box 1. The anti-chicken movable triangle plate 9 is set on the inclined top 2 of the box with a ball type movable positioning pin 10 At the top, the egg delivery mechanism is inserted into the egg passage groove 20, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com