A laser measuring head device with variable measuring range and its curved surface measuring method

A technology of laser probe and measuring range, applied in measurement devices, optical devices, instruments, etc., can solve problems such as affecting measurement efficiency, increasing measurement costs, and inability to identify the surface to be measured, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below with reference to the drawings and embodiments.

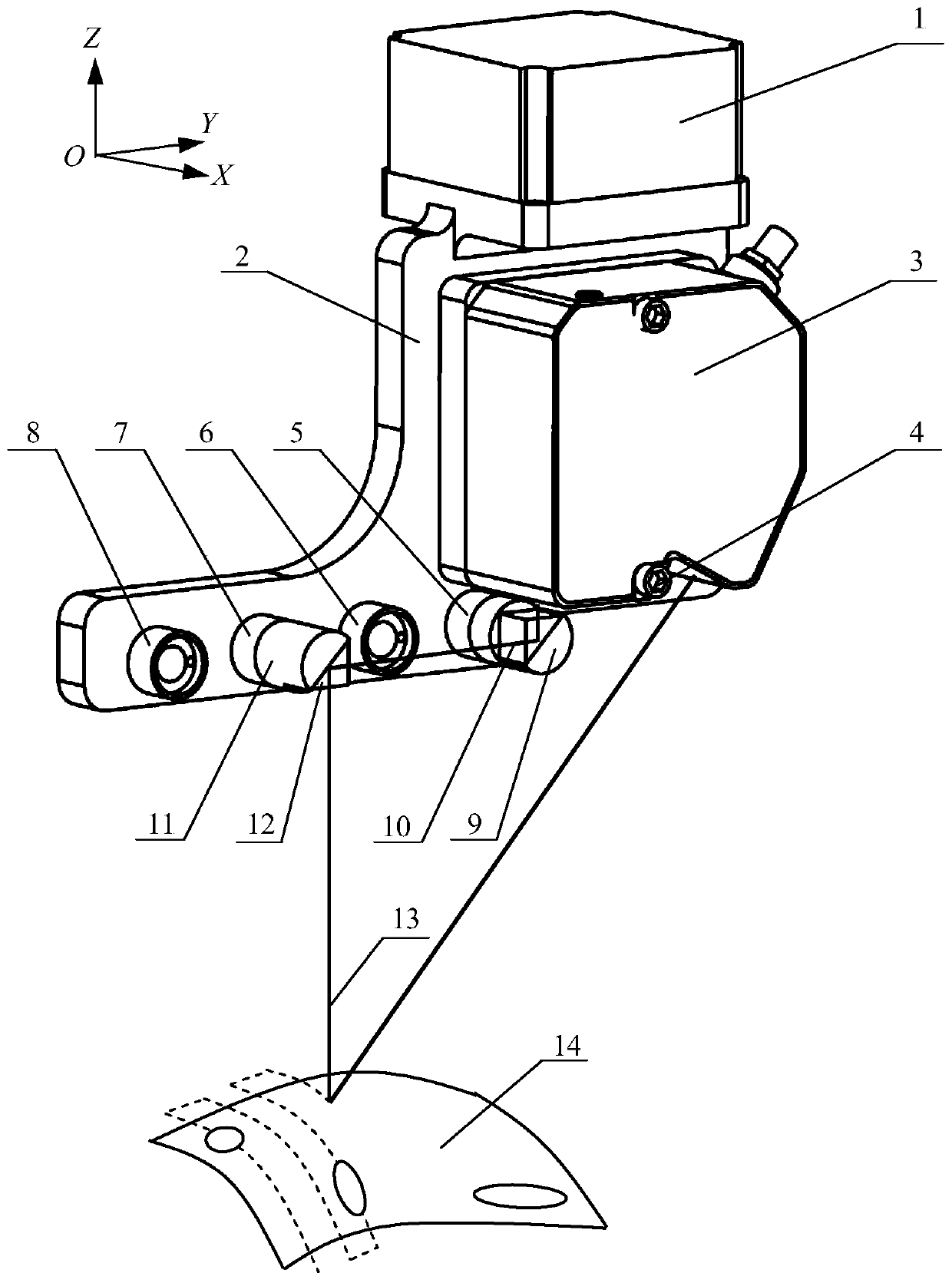

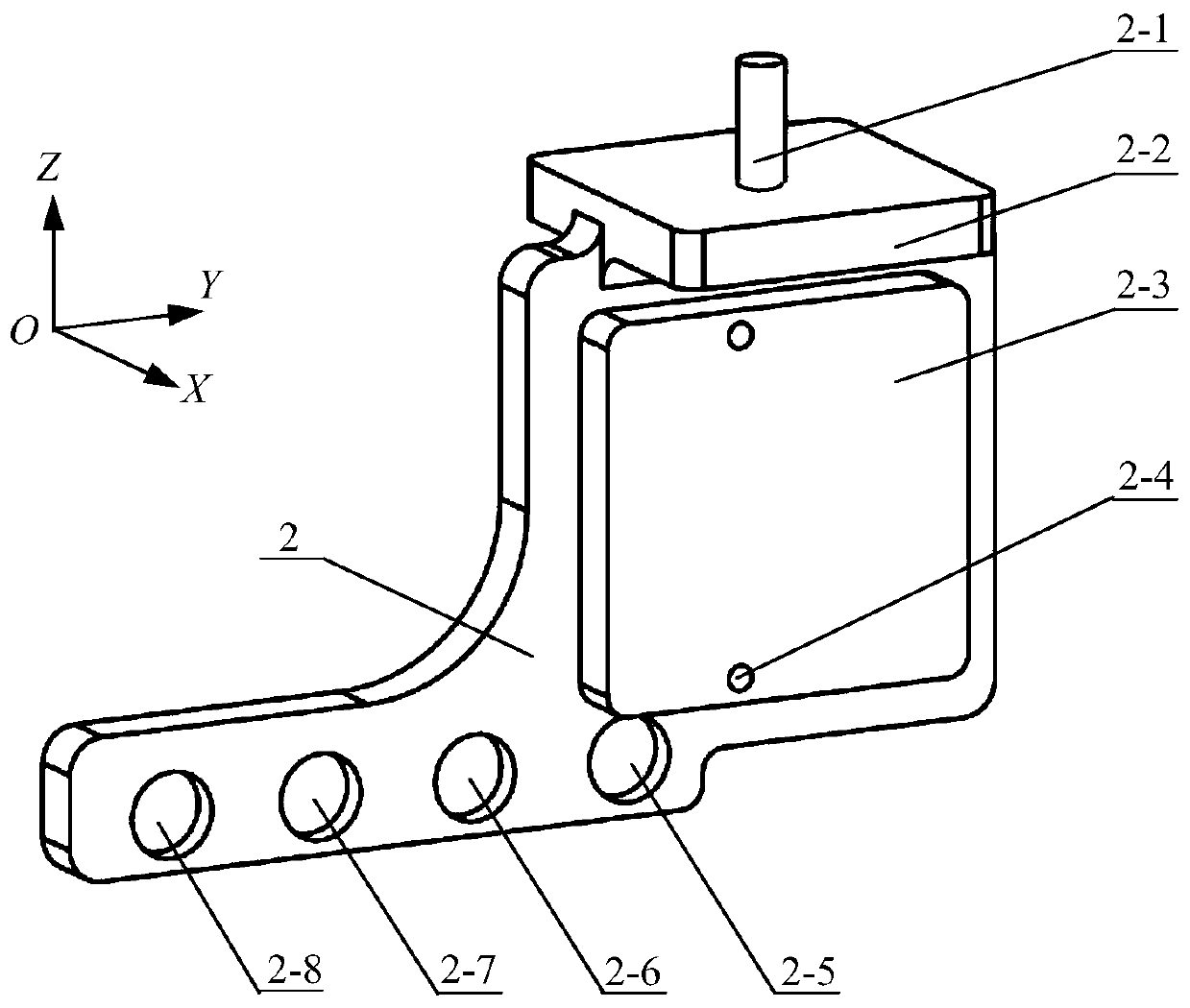

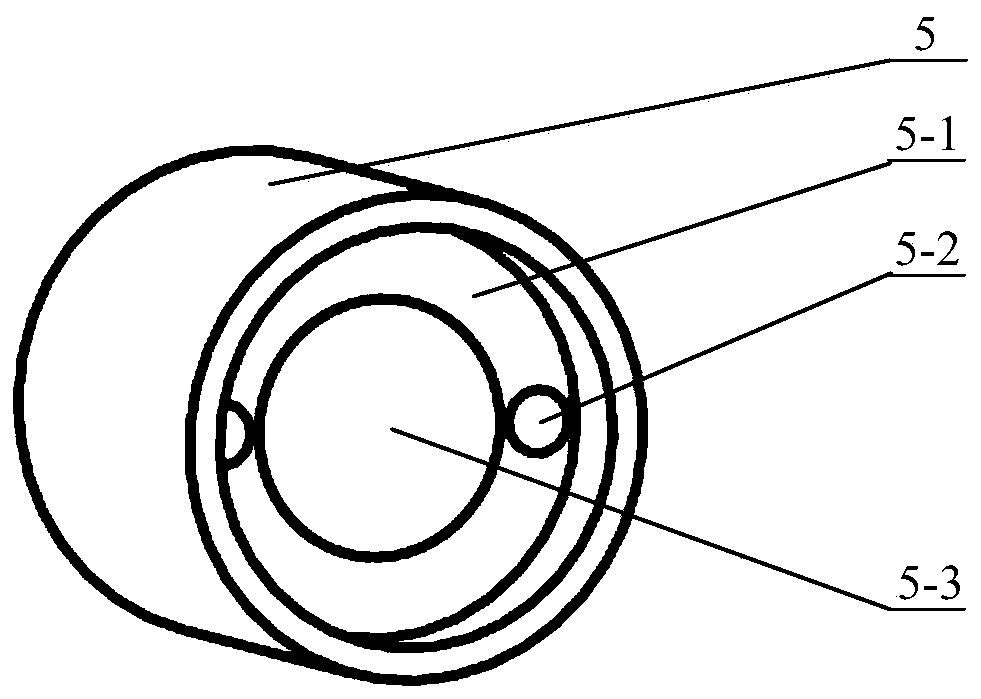

[0067] Such as figure 1 , 2 , 3 and 4, a laser probe device with variable measuring range, including the sensor main board 2, the laser probe 3, the first interface 5, the second interface 6, the third interface 7, the fourth interface 8, the first interface The prism holder 9, the first right-angle prism 10, the second prism holder 11 and the second right-angle prism 12.

[0068] Such as figure 1 with 2 As shown, the upper end of the sensor main board 2 is fixed with a connecting board 2-2, and the upper end of the connecting board 2-2 is fixed with a connecting post 2-1; the two mounting holes of the laser probe 3 and the boss 2- on the side of the sensor main board 2 The two threaded holes 2-4 on 3 are fixed by screws 4 respectively. The laser probe 3 adopts a triangulation method laser displacement sensor. The X axis of the coordinate measuring machine is the X axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com