Integrated grain barn structure for drying and storing grains

A granary and drying technology, which is applied in the direction of drying solid materials, local agitation dryers, and static material dryers, etc., can solve the problems of low drying efficiency, cumbersome drying process, and uneven drying, so as to improve efficiency and speed up diffusion , Improve the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

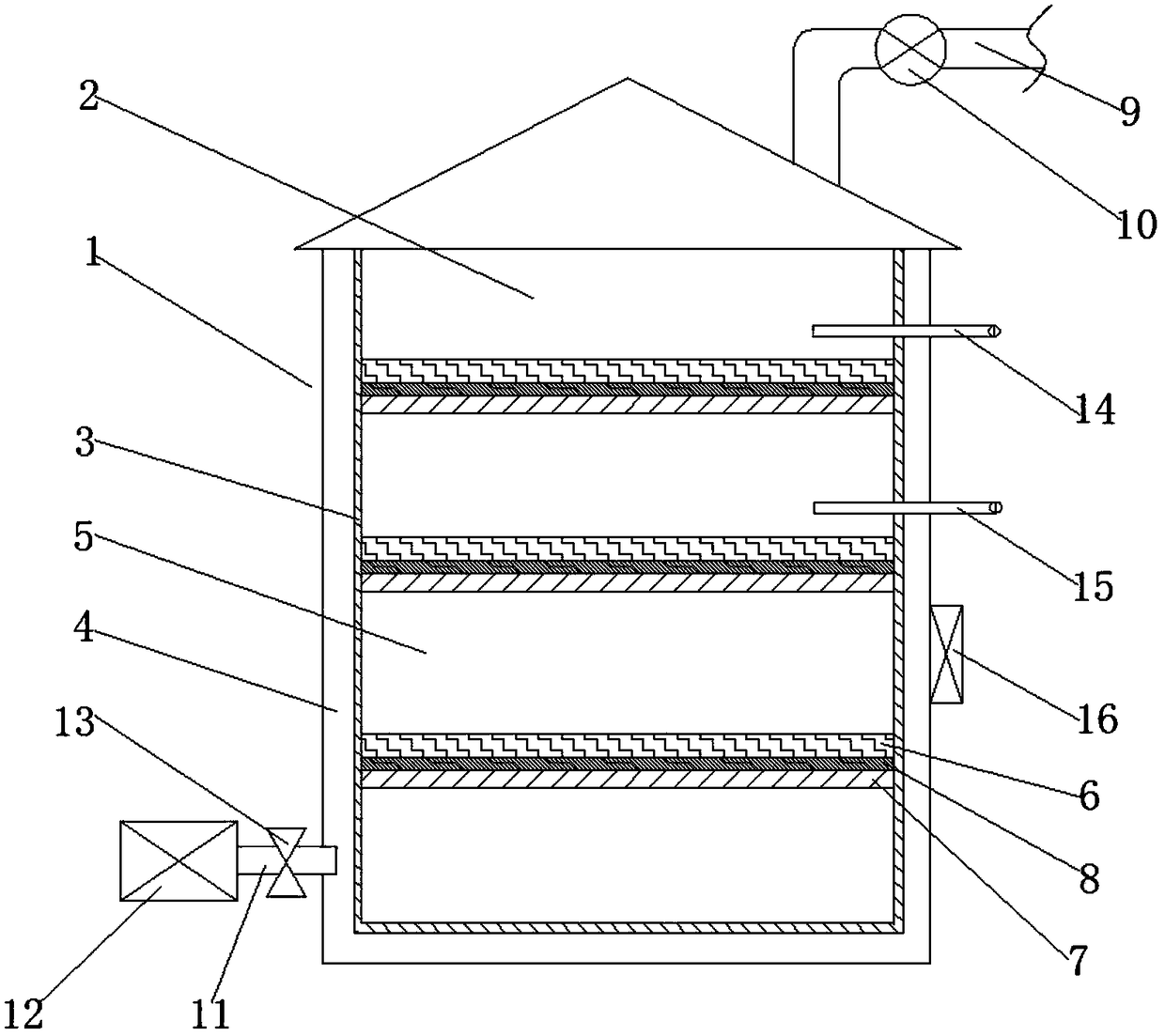

[0018] like figure 1 The shown integrated granary structure for dry grain storage includes a granary body 1, and a grain storage cavity 2 is arranged inside the granary body 1, and the cavity wall 3 of the grain storage cavity 2 is a mesh structure, and the mesh structure The mesh size of the structure is not larger than the particle diameter of the grain. A gas channel 4 is formed between the grain storage chamber 2 and the inner wall of the granary body 1. The gas channel 4 is connected with an air intake device communicating with the outside of the granary. The grain storage cavity 2 includes a plurality of grain storage units 5 arranged up and down, and a drying device is arranged between adjacent grain storage units 5, and the drying device includes a mesh partition and a drying mechanism 6 located on the mesh partition. , the mesh aperture of the mesh partition is not larger than the grain diameter, and the drying mechanism 6 is any one of a microwave dryer or an electri...

Embodiment 2

[0021] Based on Example 1, such as figure 1 As shown, the mesh partition includes a porous plate 7 and a filter screen 8 located on the porous plate 7, and the aperture of the filter screen 8 is not larger than the particle size of the grain. Through the arrangement of the perforated plate 7 and the filter screen 8 , while ensuring the stability of the grain storage unit 5 , a gas diffusion channel is formed between the grain storage units 5 to improve the drying efficiency.

Embodiment 3

[0023] Based on Example 1, such as figure 1 As shown, the exhaust device includes an exhaust pipe 9 communicating with the interior of the grain storage chamber 2, and an induced draft fan 10 is arranged on the exhaust pipe 9. Through the arrangement of the induced draft fan 10, the diffusion speed of the gas can be accelerated, and the efficiency of drying and dehumidification can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com