Actuator for flue damper of heating furnace

A technology of flue baffles and actuators, which is applied to the device for controlling the temperature of exhaust gas, regulating the discharge flow of flue gas, and regulating the atmosphere pressure in the combustion chamber. It can solve the problems of unreasonable air-fuel ratio, high energy consumption, and large excess air coefficient. , to achieve the effect of simple structure and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

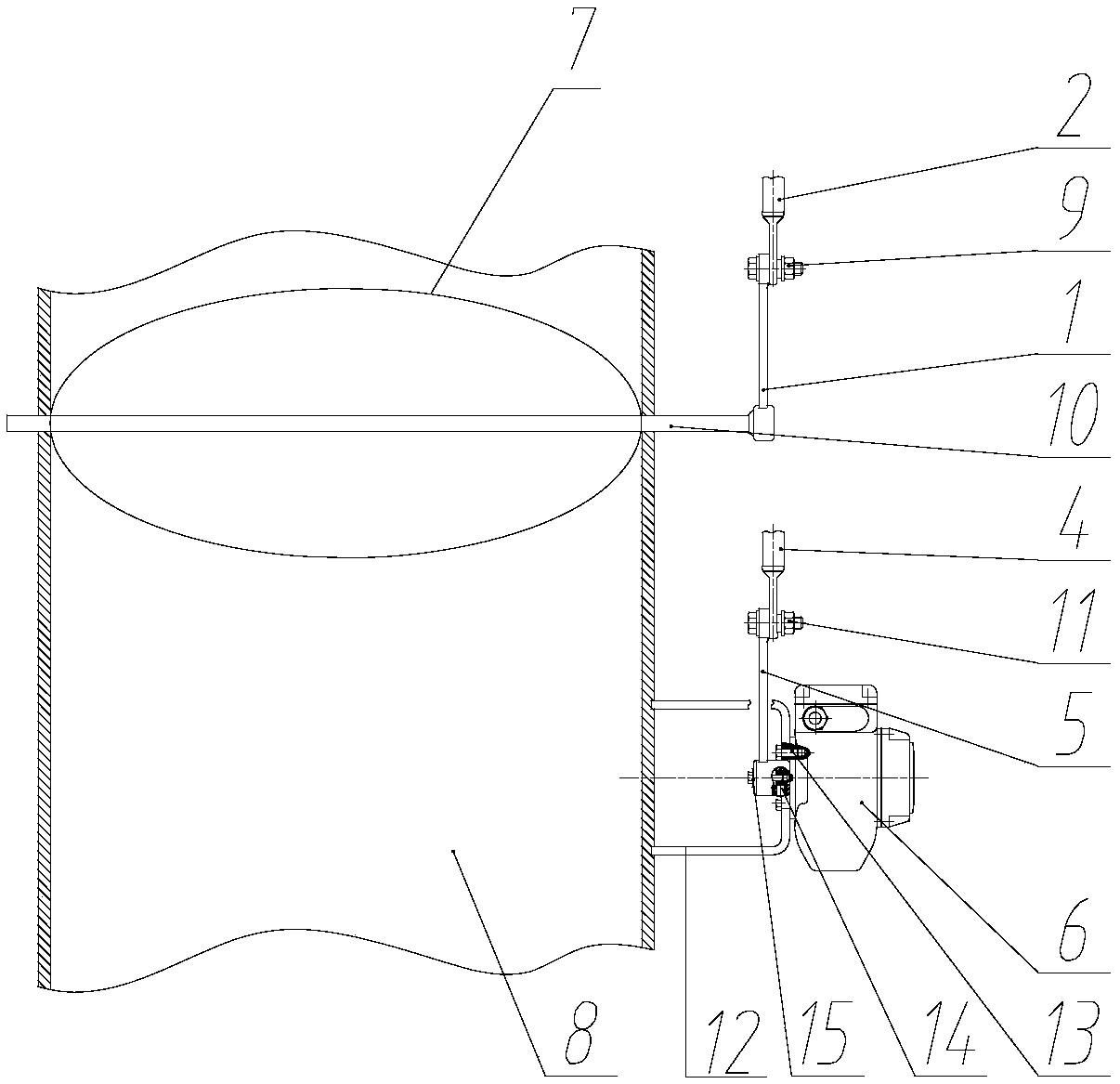

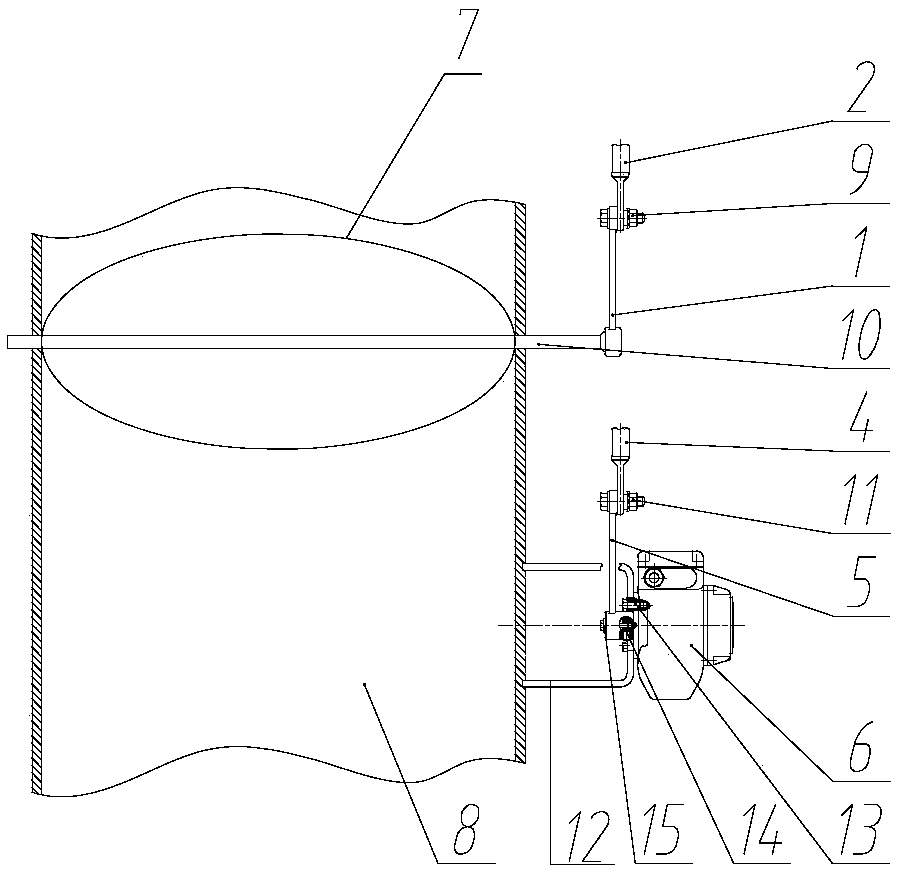

[0014] Attached below figure 1 with figure 2 , To further explain the present invention:

[0015] Such as figure 1 As shown in this embodiment, the present invention includes an electric actuator, which is the main executive structure of the present invention. The electric actuator 6 is fixed on the chimney 8 by a bracket 12. The electric actuator It is an electric actuator 6 that can realize rotation output at any angle within the range of 0-90°. In this embodiment, the electric actuator produced by Shenzhen Jiashengyuan Electromechanical Equipment Co., Ltd. is selected. The specific parameters of the product are as follows: : JLY-05Z, output torque: 50N·m, driving mode: 220v AC; signal: 4-20mA, working range: 0-90 degree range, because the present invention requires the realization of the flue baffle 0-90 degree reversal. The electric actuator 6 is located below the flue baffle mechanism.

[0016] The flue baffle mechanism described in this embodiment includes a flue baffle sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com