Method for reinforcing curved bridge through prestressed carbon plate

A prestressed, curved surface technology, applied in bridges, bridge maintenance, bridge reinforcement, etc., can solve the problems of carbon fiber board damage, carbon board stress concentration, construction difficulties, etc., and achieve the effect of widening the application range and smooth uneven surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and the following embodiments. The following embodiments are only used to illustrate the present invention, not to limit the present invention.

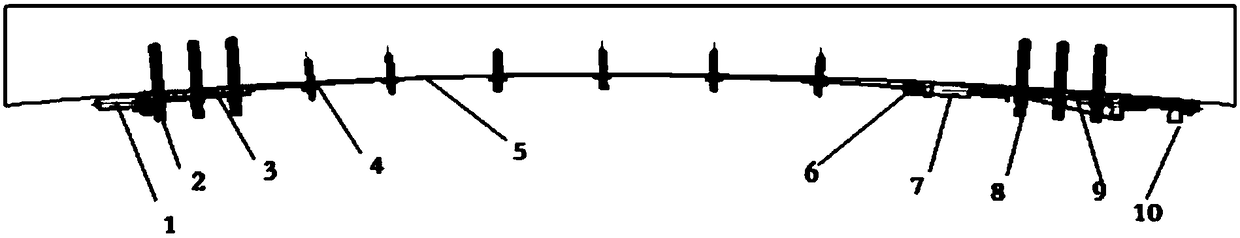

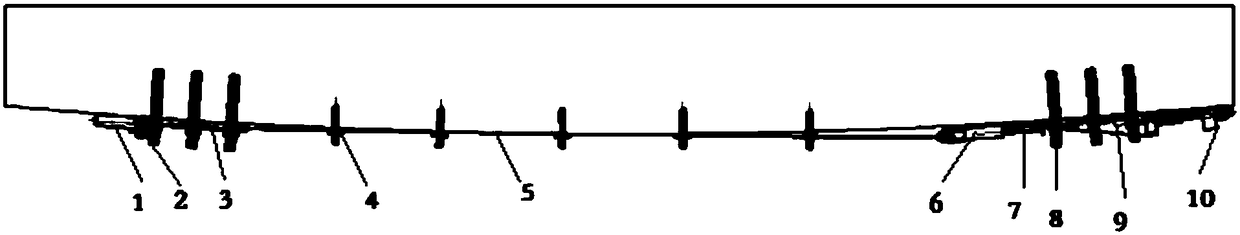

[0026] S1: if figure 2 and image 3 As shown, the concrete base surface constructed by the present invention is arc-shaped or similar to arc-shaped, and the radian is 3-6 °; first, the construction concrete base surface to be reinforced is drawn to determine the installation position of the carbon fiber plate 5; The concrete base surface shall be drilled according to the national standard, and the holes shall be cleared and the concrete base surface shall be cleaned;

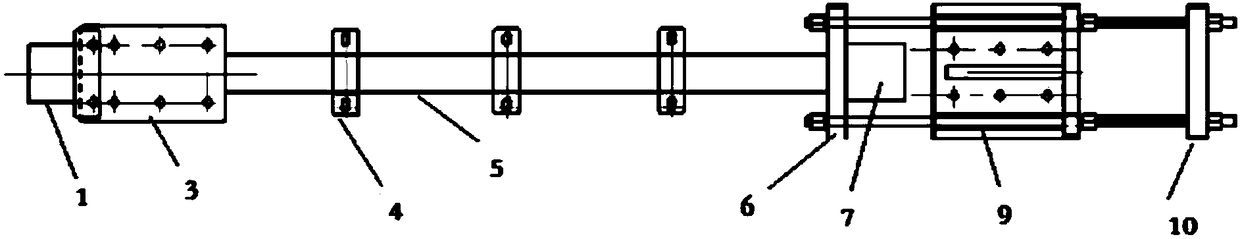

[0027] S2: if figure 1 As shown, the anchor head 1 at the fixed end and the anchor plate 3 at the fixed end are fixed on the fixed end of the concrete base with the chemical anchor bolt A2, so that the anchor bolt and the concrete are bonded to bear the force t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com