Jetting roller capable of achieving solution uniform distribution

A solution spraying and roller technology, applied in liquid spraying devices, spraying devices, etc., can solve problems such as uneven spraying, and achieve the effect of reducing different spraying amounts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

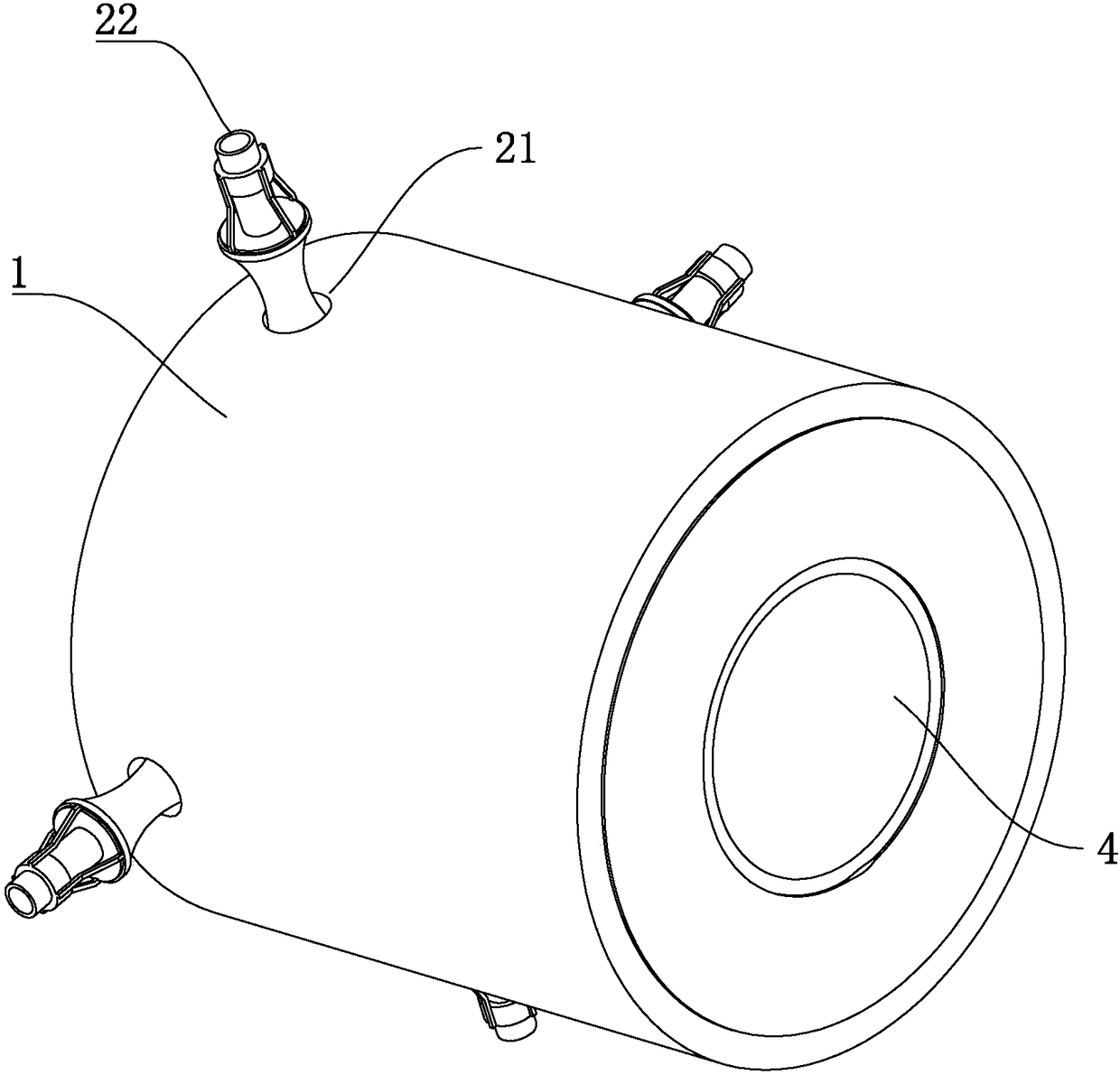

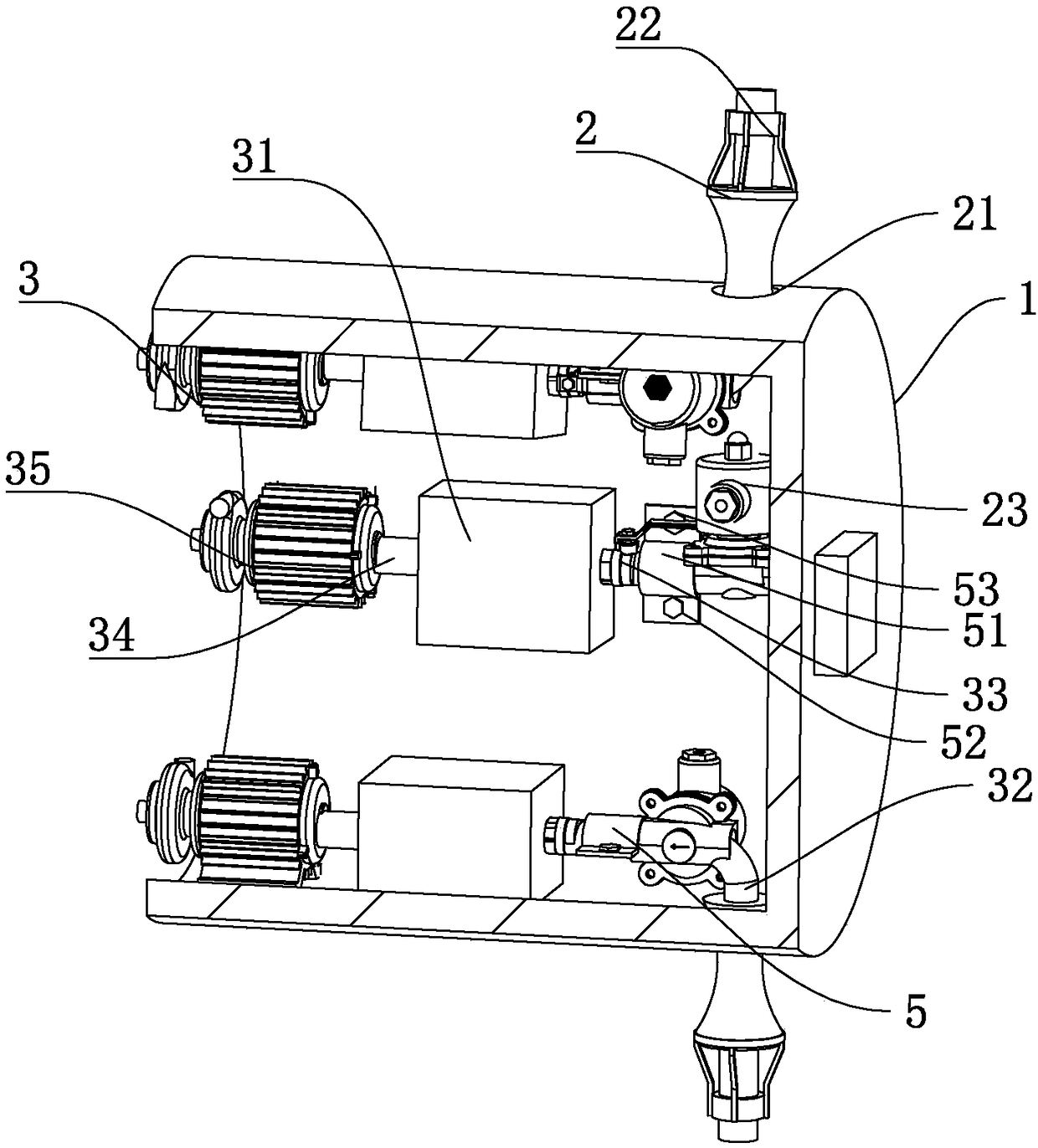

[0022] Embodiment 1: a kind of evenly distributed solution spraying roller, such as figure 1 and figure 2 As shown, the cylinder body 1 is included, and the cylinder body 1 is provided with a spraying device 2. The spraying device 2 includes through holes 21 arranged around the cylinder body 1, and several through holes 21 are wound into a circle. A nozzle 22 is provided, and a liquid pipe 32 connected to the nozzle 22 is also provided in the cylinder body 1. An electromagnetic control valve 23 is provided at the end of the liquid pipe 32 near the nozzle 22, and an electromagnetic control valve 23 is provided on the outer wall of the cylinder body 1 for unification. A controller for controlling the electromagnetic control valve 23, and a pressure valve 33 is provided at the end away from the spray head 22. The injection device 2 is also provided with a distribution device 3, and the distribution device 3 is also provided with a protective shell 4 fixed on the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com