Preparation method for zeolite membrane taking glass hollow fiber as carrier

A glass fiber and molecular sieve technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as unsatisfactory separation efficiency, affecting the efficacy and development of molecular sieve membranes, and lack of orientation in crystal membranes , to achieve the effects of enhancing toughness, accelerating water absorption efficiency, improving solubility and degradation ability

Inactive Publication Date: 2018-09-04

邹峰

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

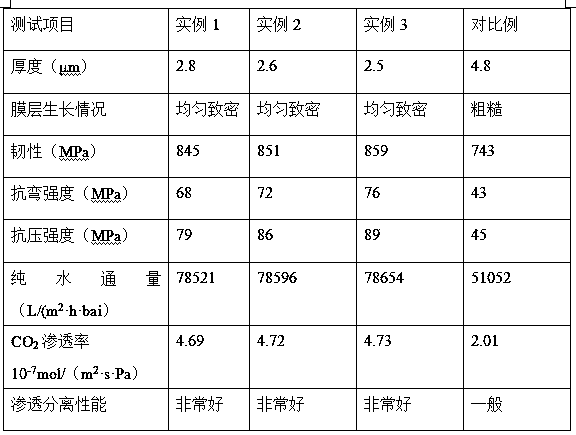

[0009] However, in order to have a certain mechanical strength for the common molecular sieve membranes at present, the thickness of the membrane obtained during the preparation process is relatively large, resulting in that the separation efficiency cannot reach the ideal state. How to reduce the thickness of the molecular sieve membrane and improve its separation efficiency? The mechanic

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of zeolite membrane preparation, in particular to a preparation method for a zeolite membrane taking a glass hollow fiber as a carrier. A glass fiber braided tube is coated with aluminium oxide and silicon dioxide to obtain a hollow fiber membrane, oxidation liquid is subjected to termination reaction with glycol to obtain mixed liquid, the mixed liquidis put in a dialysis bag for dialysis, dialysis purified liquid is obtained, white flocculent products, a gelatin solution, cobwebs and the like are mixed and stirred to obtain a thick glue solution,palm oil is added, the mixture is heated and stirred for emulsification to obtain gel liquid, and the hollow fiber membrane is coated with the gel liquid and is subjected to pressurization and ventilation to obtain the zeolite membrane. A sodium hydroxide solution in electrolyte has a degreasing effect on the glass fiber braided tube, a polymer of aluminium oxide and silicon dioxide is produced and deposited on the surface of the braided tube to form a molecular sieve, parts of oxidized sodium alga acid can form hydrogel with a high-molecular compound through chemical crosslinking due to thefact that active group aldehyde group is introduced in, the mass transfer rate of water molecules is improved, and the application prospect is broad.

Description

technical field [0001] The invention relates to the technical field of molecular sieve membrane preparation, in particular to a method for preparing molecular sieve membranes with glass hollow fibers as carriers. Background technique [0002] Membrane separation is a separation technology developed in recent years, which uses one or more substances to pass through a semi-permeable barrier (membrane) faster than other substances to achieve the separation of feed mixtures containing two or more the goal of. Membrane separation technology mainly includes microporous filtration, ultrafiltration, reverse osmosis, nanofiltration, electrodialysis, gas separation and total evaporation. [0003] Molecular sieve is a microporous inorganic crystal material formed with silicon-oxygen tetrahedron and aluminum-oxygen tetrahedron as the basic skeleton. It is a new type of inorganic membrane material developed in recent years that can realize molecular sieve. It has broad application pros...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01D69/08B01D67/00B01D71/02

CPCB01D67/0079B01D69/08B01D71/028

Inventor 邹峰何伟仁张建初

Owner 邹峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com