Composition for polyurethane foam

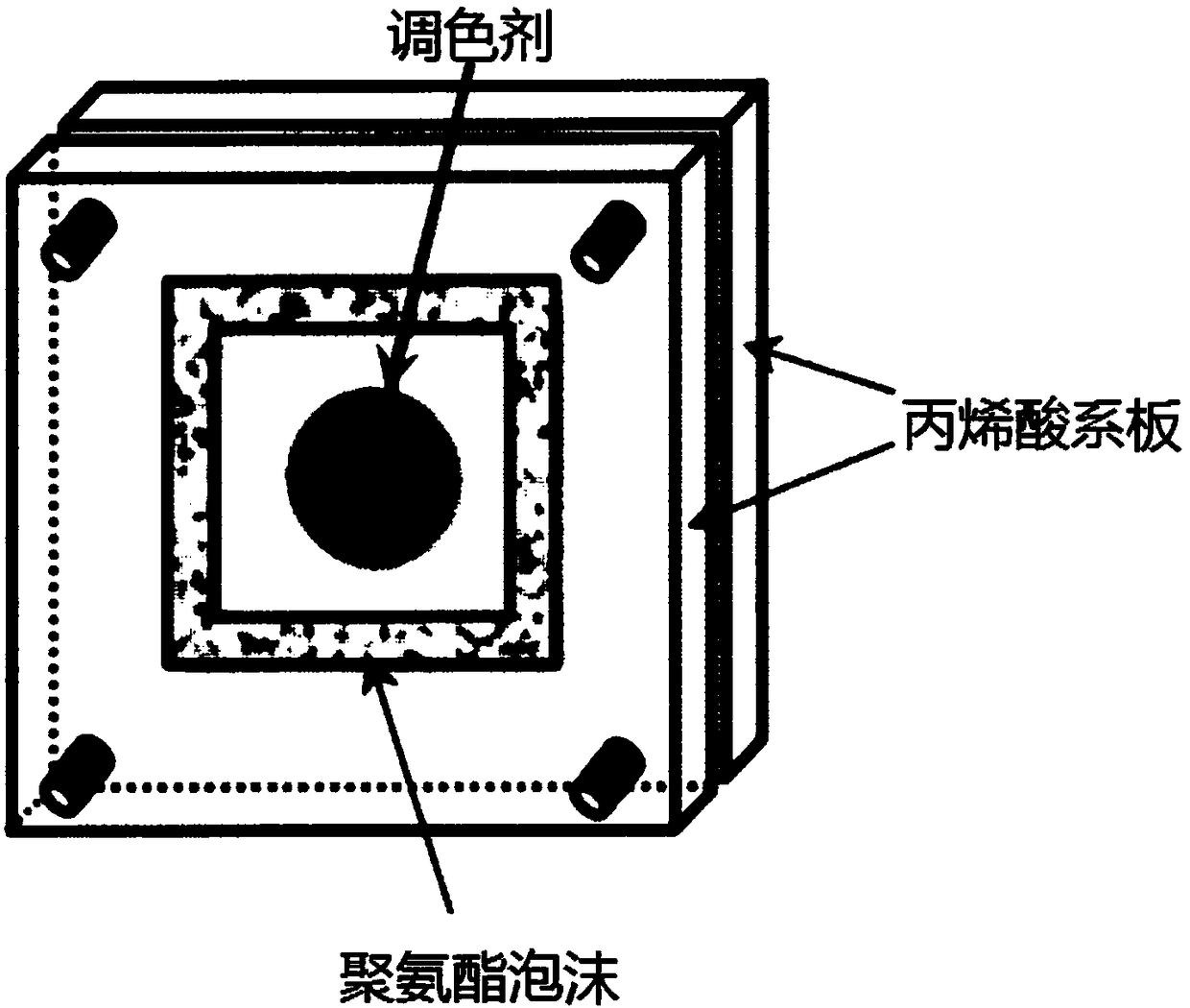

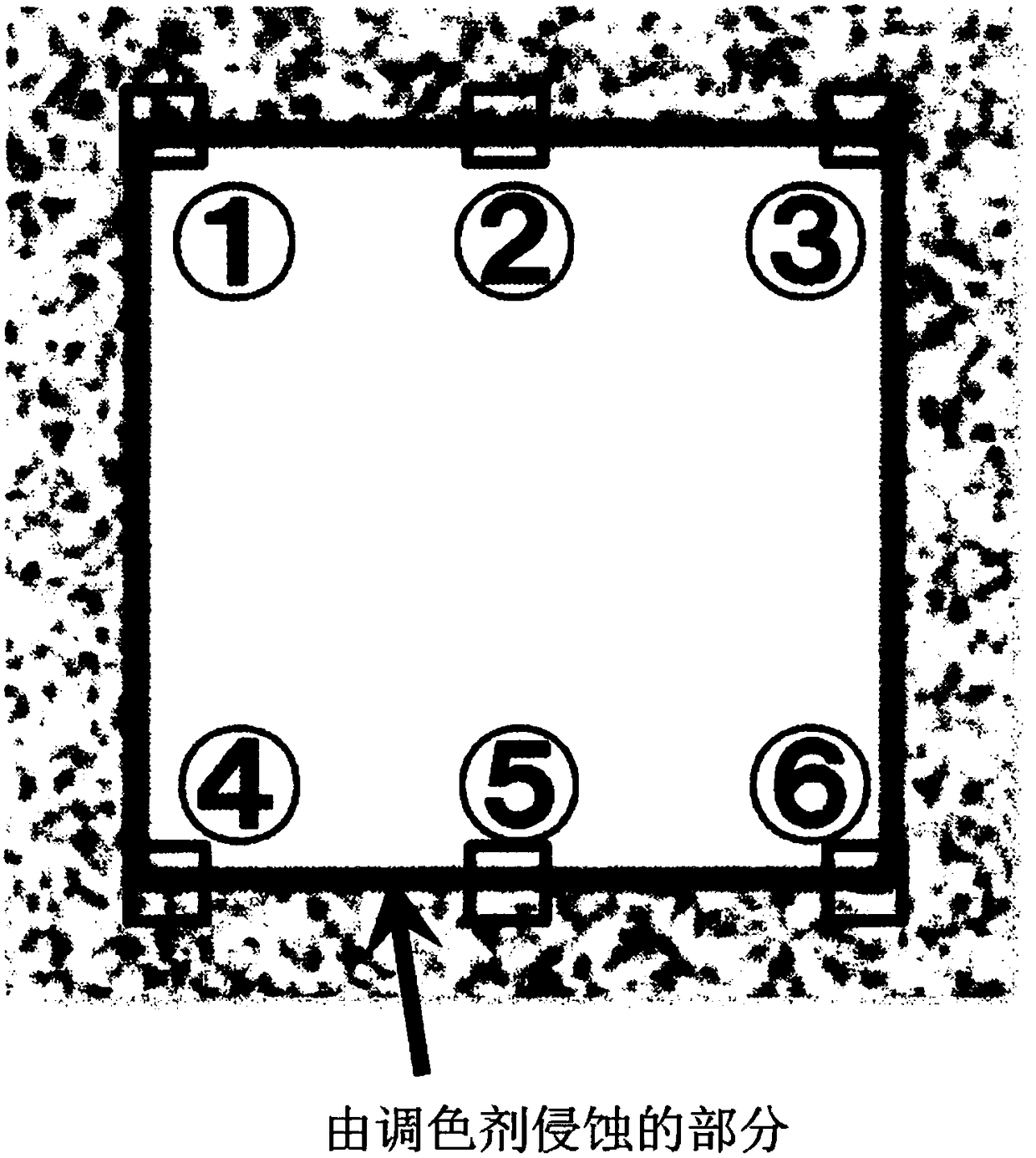

A technology of polyurethane foam and composition, which is applied in the direction of electrical recording technology using charge graphics, equipment and instruments using electrical recording technology using charge graphics, which can solve problems such as poor images and toner leakage, and achieve excellent recovery , Excellent toner sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 20 and comparative example 1

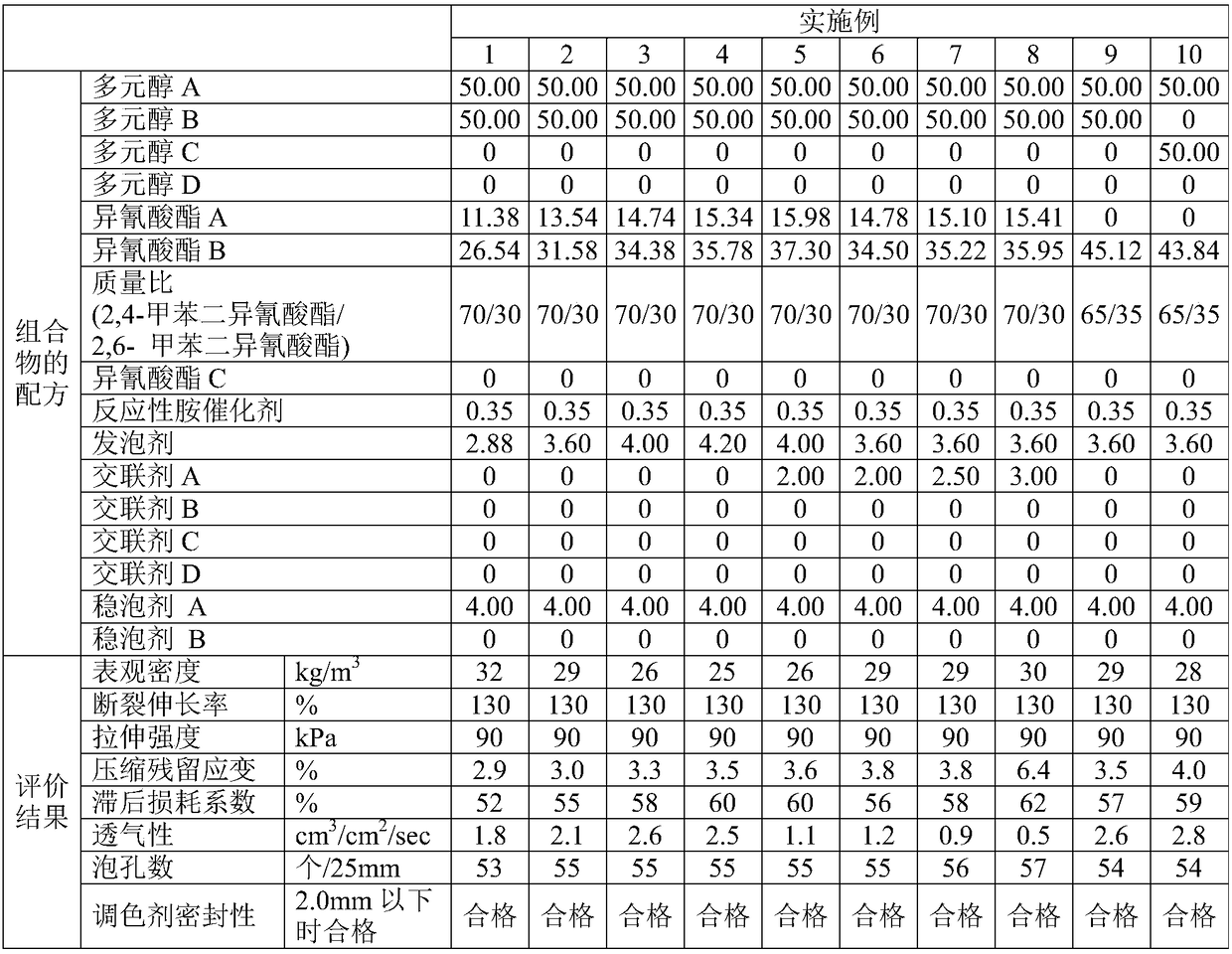

[0133] The polyurethane foam raw materials shown in Table 1 were mixed and foamed at atmospheric pressure at 20° C. by a one-step method and a flat plate foaming method to produce 21 kinds of polyurethane foams. The obtained polyurethane foam was subjected to the above-mentioned evaluation. The results are shown in Table 1. The numerical values in the rows of the formulations of the compositions in Table 1 are parts by mass except for the mass ratio.

[0134] Table 1

[0135]

[0136] Table 1 (continued)

[0137]

[0138] As is clear from Table 1, compared with the toner seal material produced from the polyurethane foam of Comparative Example 1, the toner seal materials produced from the polyurethane foams of Examples 1 to 20 were able to secure excellent properties of the polyurethane foam. Simultaneously with the toner sealability, the tensile strength of the polyurethane foam was shown to increase, and its compressive residual strain and hysteresis loss coefficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com