Method for regulating the processing of a material web by means of positioning marks and device for carrying out the method

A positioning marking and processing device technology, which is applied in the processing of packaging material format and the field of packaging material format device, can solve problems such as unsatisfactory solutions, and achieve accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

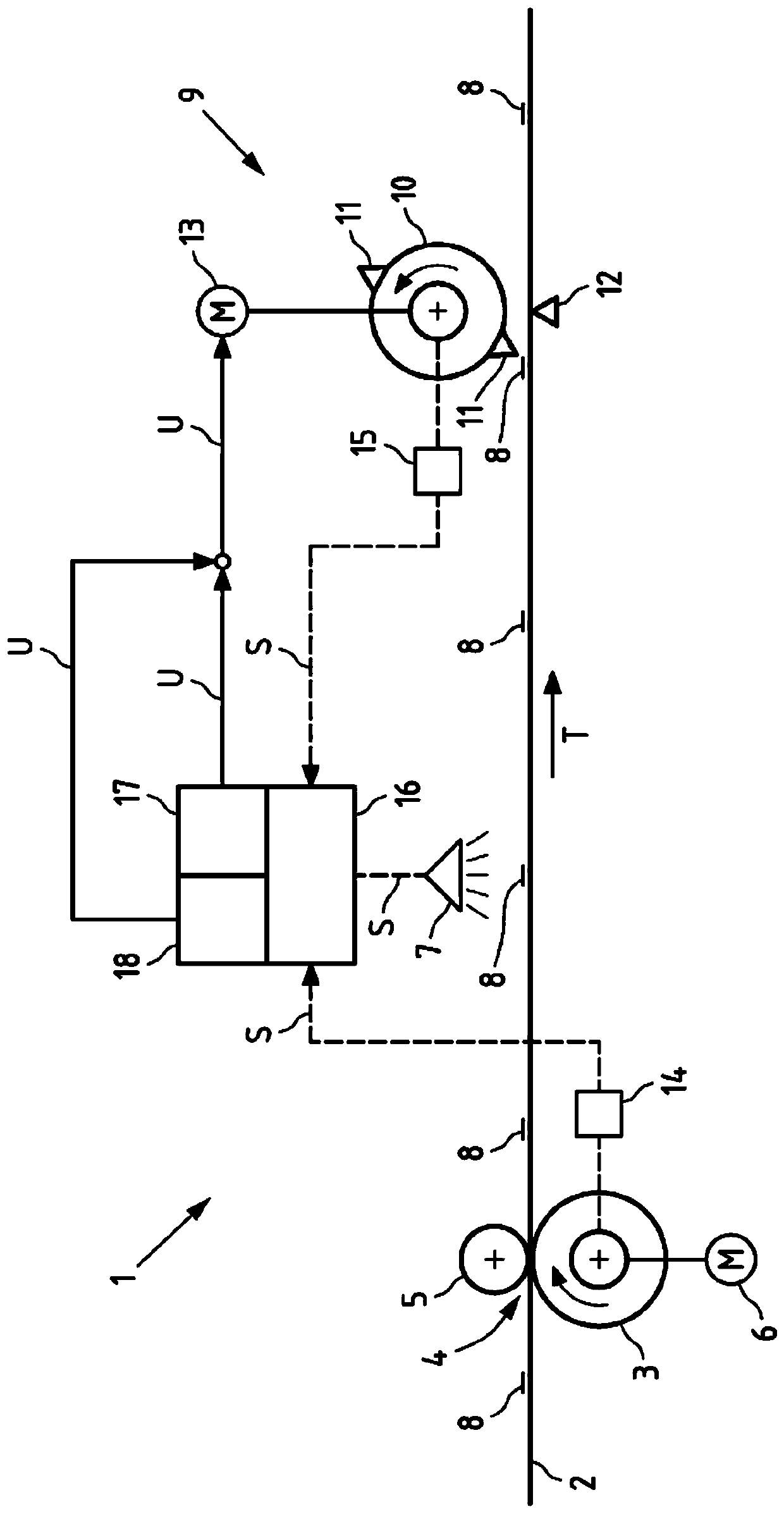

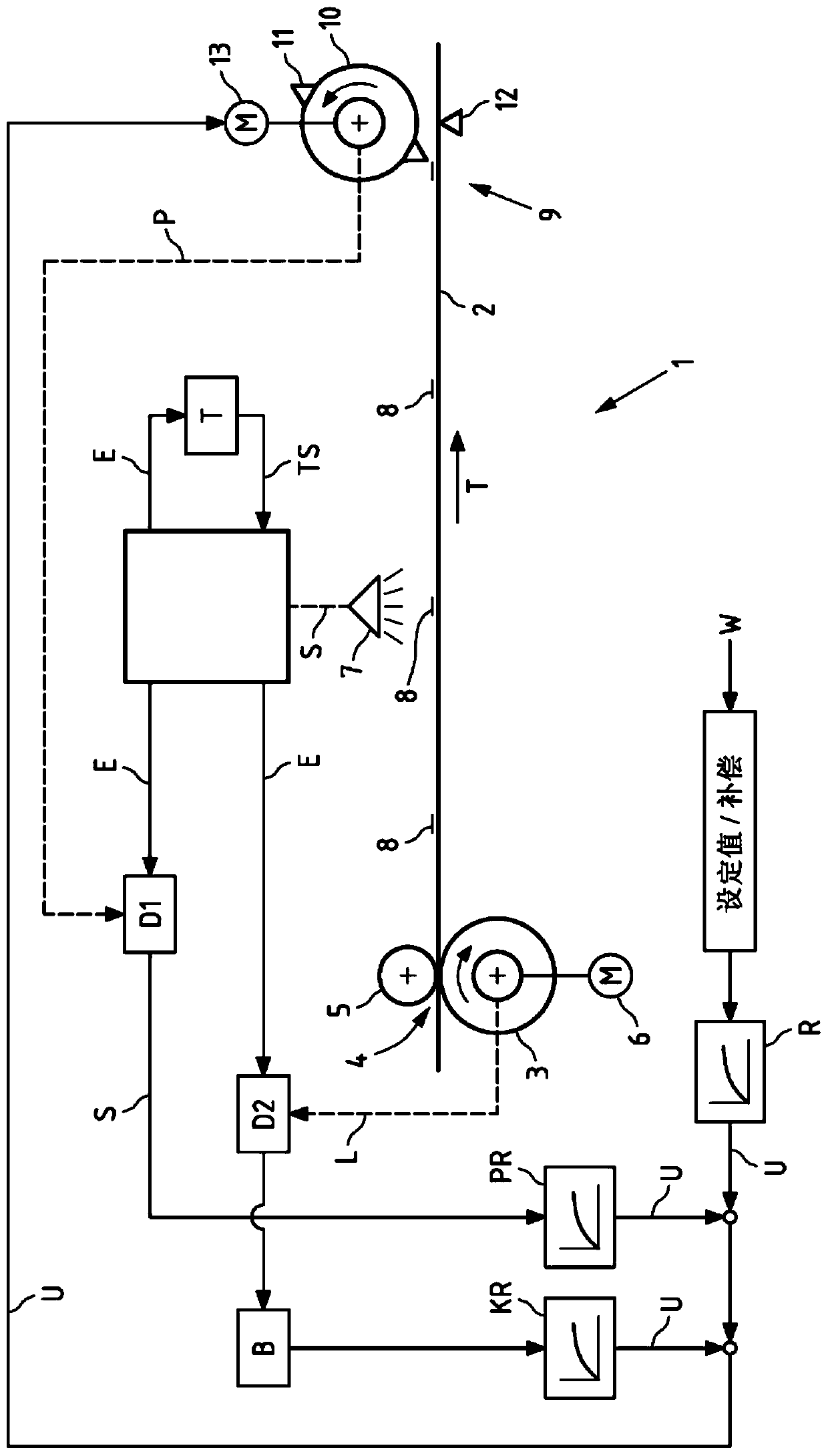

[0047] figure 1A device 1 for processing a material web 2 in the form of a packaging material web produced from a packaging material laminate is shown. The packaging material laminate is a paperboard / plastic laminate having a paperboard layer, an aluminum layer and an external printed polyethylene layer. The material web 2 can be unwound from a take-up roller or transported to the device 1 in some other way. The material web 2 is conveyed linearly through the device 1 shown and preferred here. But this is not mandatory, but the illustration is simplified. In the shown and preferred device 1 , the material web 2 is driven by a drive roller 3 , and for this purpose it is guided through a nip 4 between the drive roller 3 and the pressure roller 5 . The nip 4 is so narrow that a frictional connection between the drive roller 3 and the material web 2 can occur. The drive roller 3 is driven by a drive 6 , in particular by a motor drive.

[0048] Here, the material web 2 is tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com