Device and method for cleaning hole and filtering residue of cast-in-place pile

A technology for filtering slag and clearing holes, which is applied to sheet pile walls, buildings, and infrastructure engineering, etc. It can solve the problems of limited effect, long time for cleaning holes and slag discharge, and difficulty in repeated use, so as to reduce the required cost and reduce the number of preparations , the effect of shortening the cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

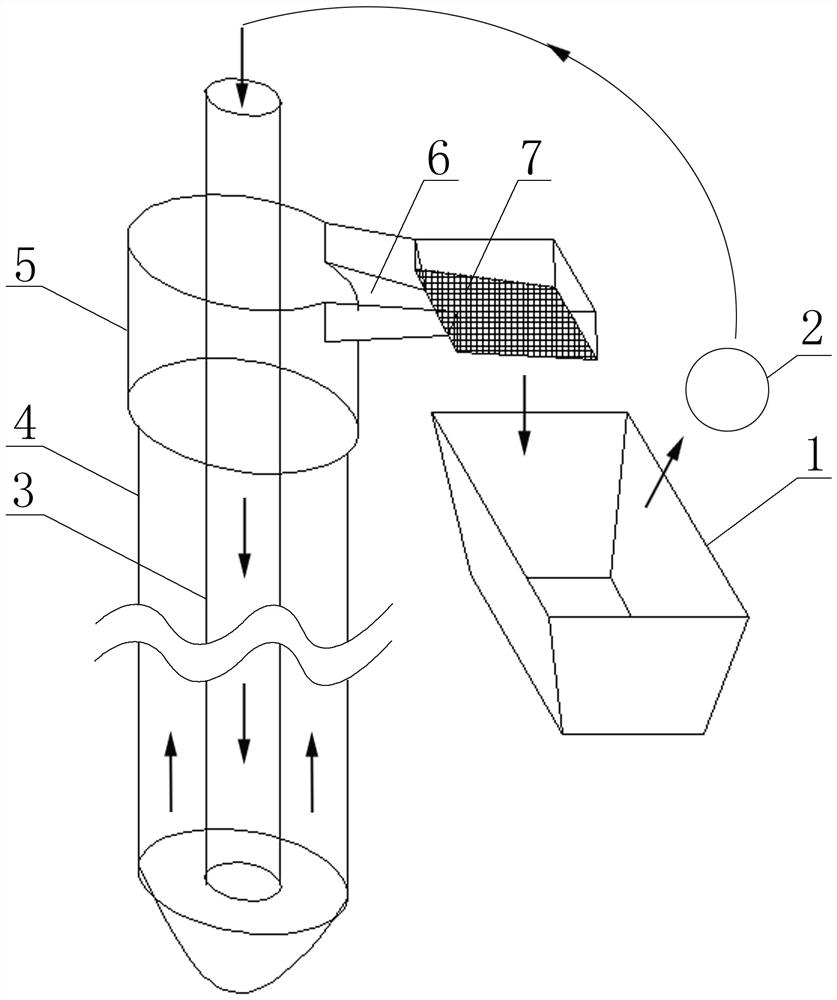

[0026] A device for clearing holes and filtering residues of cast-in-situ piles, including a mud pool 1, a mud pump 2, a mud delivery pipe 3, an overflow guide groove 6, and a screen 7, the suction end of the mud pump 2 is placed in the mud pool 1, and the output of the mud pump 2 is end is connected with the upper end of the mud conveying pipe 3, the mud conveying pipe 3 is placed in the pile hole 4 and the lower end of the mud conveying pipe 3 is close to the bottom of the pile hole 4, and the casing 5 at the upper end of the pile hole 4 is provided with a gap for the mud to overflow. One end of the overflow channel 6 is connected to the gap on the casing 5, the other end of the overflow channel 6 is connected to the screen 7, the screen 7 is located above the mud pool 1, and the screen 7 is connected to the overflow channel 6 One end is close to the bottom surface of the overflow channel 6, the two sides of the screen 7 are provided with baffles to prevent the mud from flowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com