A high pressure plate and frame filter press with retractable filter plate

A high-pressure plate and frame and filter press technology, which is applied in filtration separation, separation methods, sludge treatment and other directions, can solve the problem that the conventional plate and frame filter press and diaphragm type plate and frame filter press cannot be completely replaced, and the operation process is long. and other problems, to achieve the effect of easy operation and maintenance, light weight and simple mud discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The purpose of the present invention will be further described in detail through specific examples below, and the examples cannot be repeated here one by one, but the implementation of the present invention is not therefore limited to the following examples.

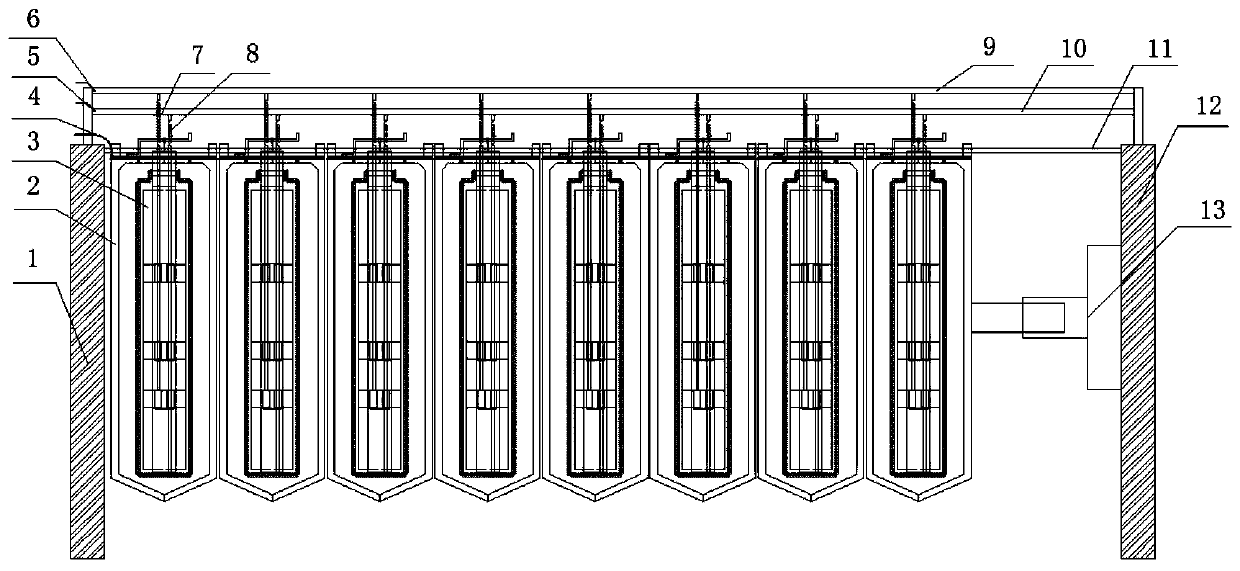

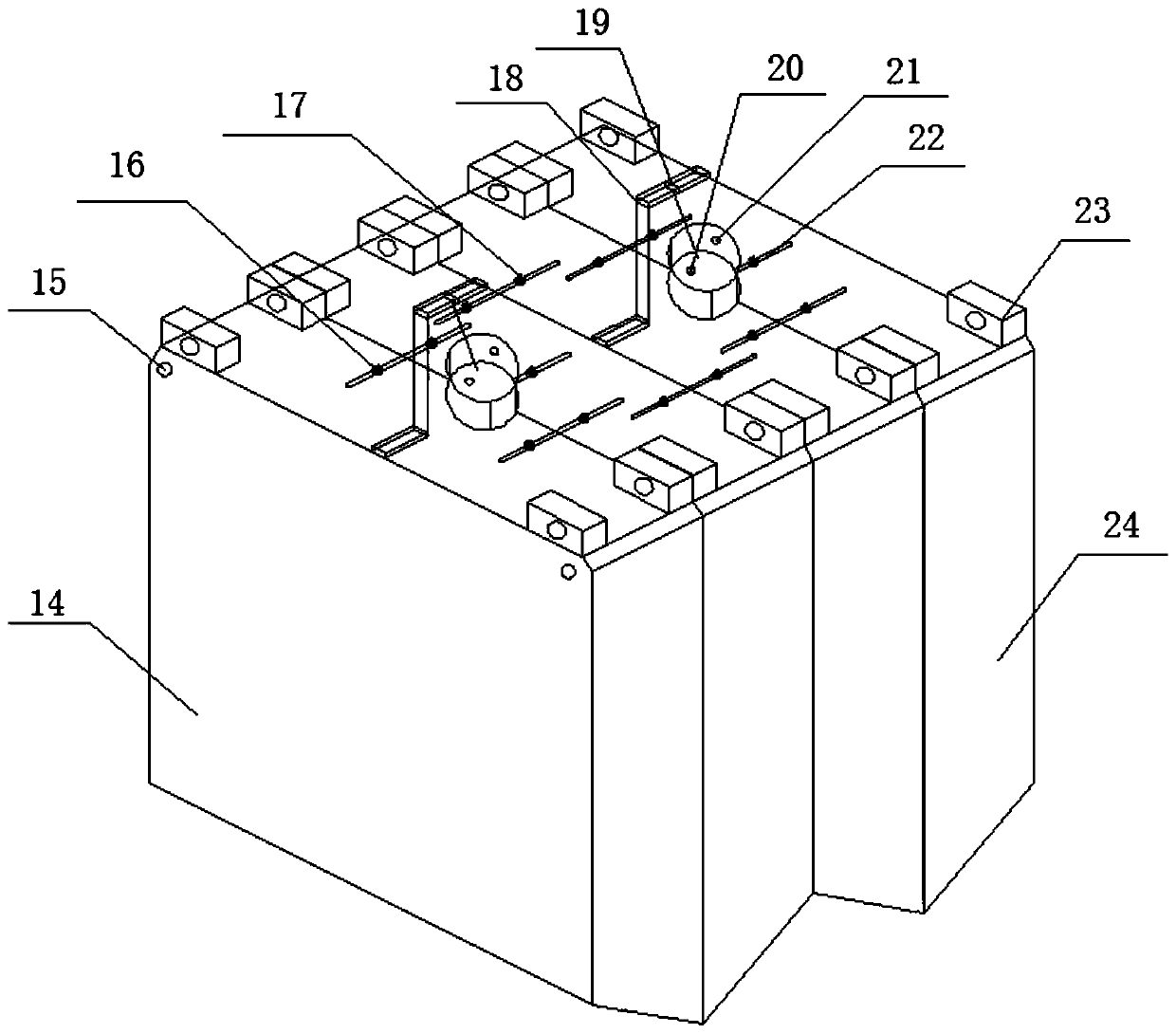

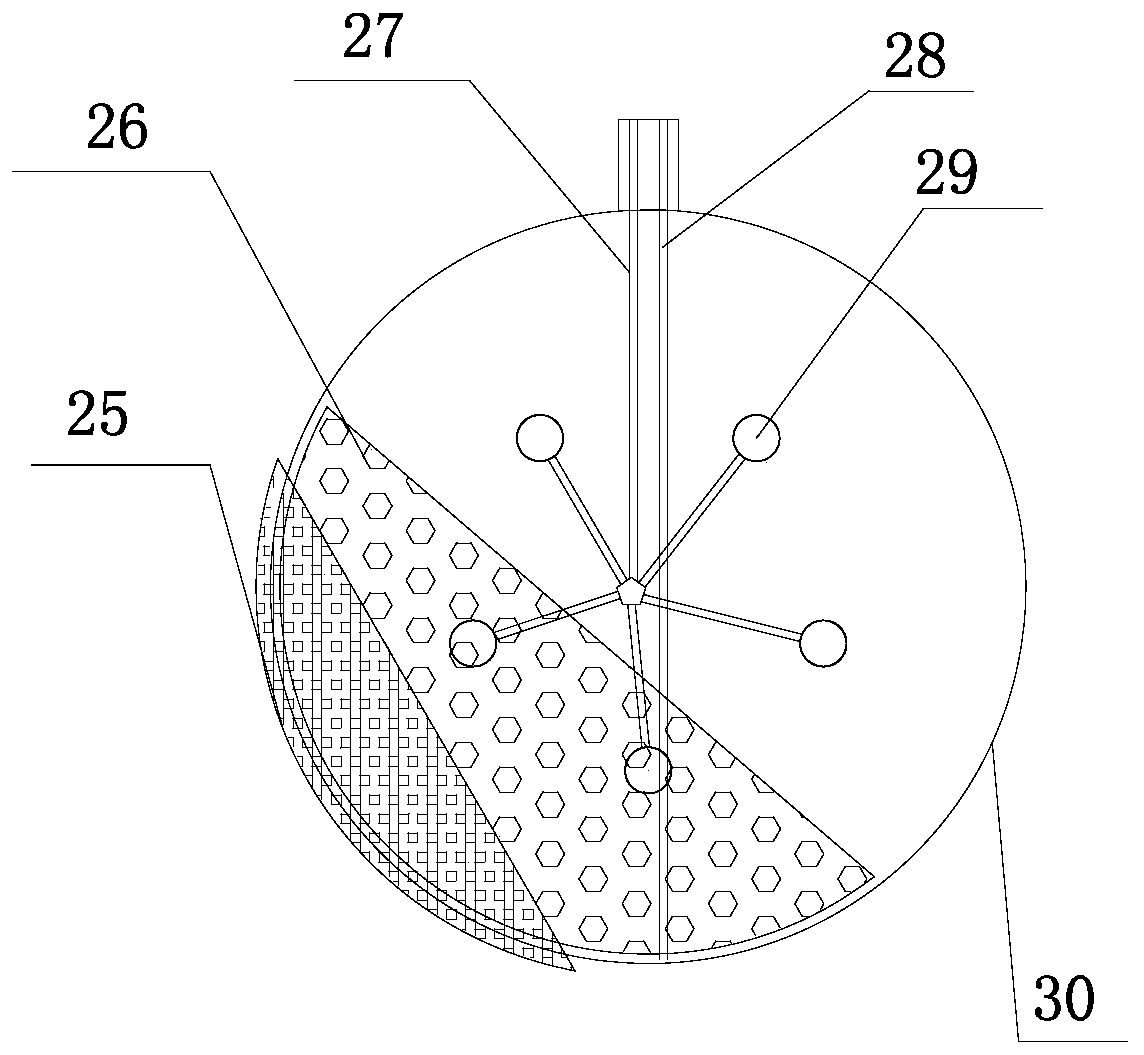

[0031] like figure 1As shown, a high-pressure plate-and-frame filter press with a retractable filter plate includes a first fixed plate 1, a second fixed plate 12, a hydraulic device 13 fixed on the second fixed plate, and a horizontal plate supported by a plate frame. The tubes 11 are sequentially movably superimposed on a plurality of combined plate frames 2 arranged between the first fixed plate 1 and the telescopic end of the hydraulic device 13, and the hydraulic stroke of the hydraulic device 13 should be long enough to Open all plates and frames for mud drainage. The first fixed plate 1 and the second fixed plate 12 can be made of conventional steel, and the bottom of the two fixed plates can be fixed on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com