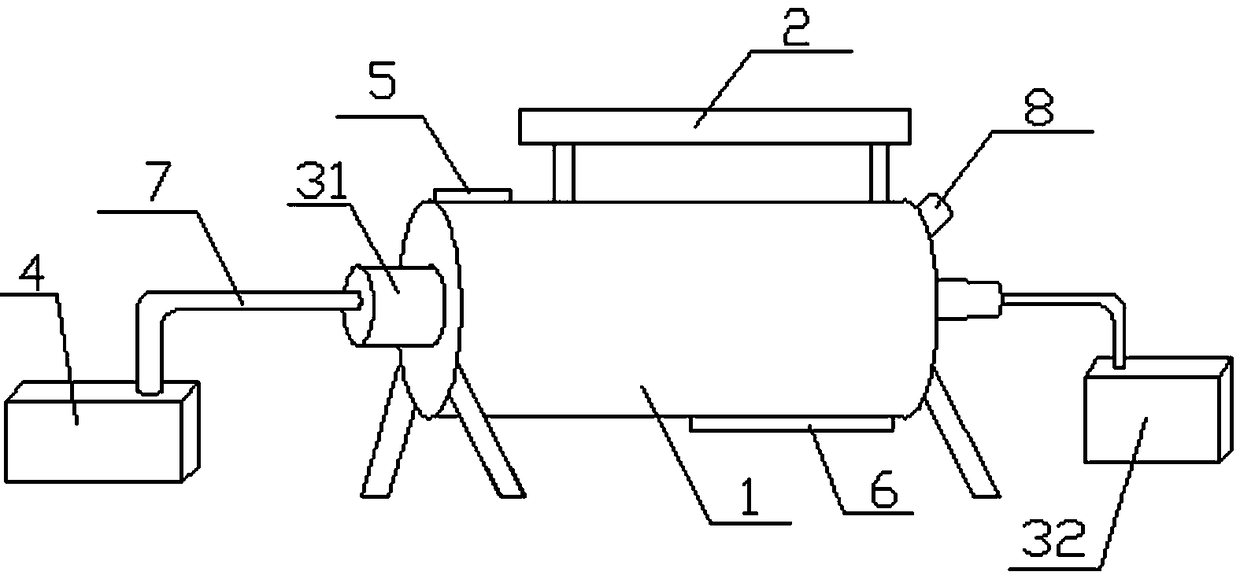

Dual-heat source dynamic baking device and baking method and application thereof

A baking device and baking technology, applied in the field of baking, can solve the problems of material adhering to the inner wall, low baking efficiency, poor baking quality, etc., so as to reduce the damage of high temperature or high-intensity radiation, improve nutritional value, and improve baking efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

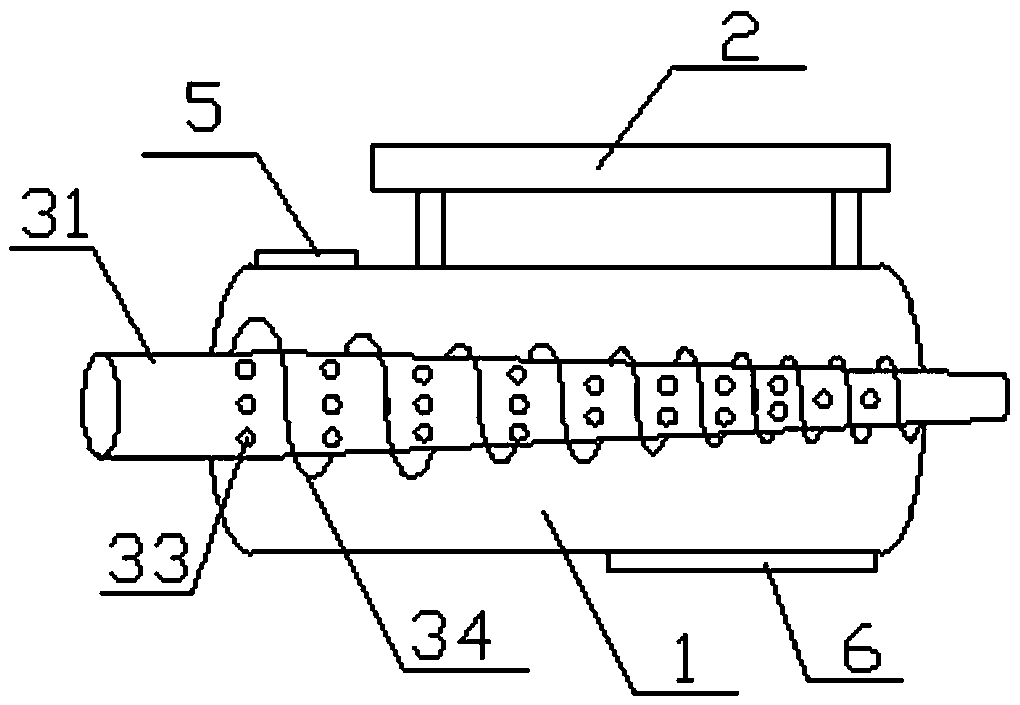

[0034] The baking process of using the baking device to bake Wuyi rock tea is realized by the following technical measures:

[0035] 1. Put 300kg of Wuyi rock tea to be baked into the baking tank 1 through the feeding port 5, turn on the rotating shaft 31 to make it rotate, adjust the rotating speed of the rotating shaft 31 to 150rpm, rotate for 5min, shake the tea leaves, and ensure The tea leaves are fully stir-fried and evenly heated, which is convenient for baking and improves production efficiency; turn on the heating fan 4, adjust the temperature of the hot air to 200°C, and input hot air into the baking tank 1 to pre-bake the tea leaves for 18 minutes;

[0036] 2. Start the xenon light source system 2 to make the light source warm up and stabilize, and bring the adjustment to TiO 2 Or adjust the thickness of ZnO nano-coating to 5 μm, adjust the color temperature of the light source to 800K and bake for 20 minutes to complete the first stage of baking; put the adjustment...

Embodiment 2

[0038]The baking process of using the baking device to bake Wuyi rock tea is realized by the following technical measures:

[0039] 1. Put 400kg of Wuyi rock tea to be baked into the baking tank 1 through the feeding port 5, turn on the rotating shaft 31 to make it rotate, adjust the rotating speed of the rotating shaft 31 to 180rpm, rotate for 8min, shake the tea leaves, and ensure The tea leaves are fully stir-fried and heated evenly, which is convenient for baking and improves production efficiency; turn on the heating fan 4, adjust the temperature of the hot air to 250°C, and input hot air into the baking tank 1 to pre-bake the tea leaves for 20 minutes;

[0040] 2. Start the xenon light source system 2 to make the light source warm up and stabilize, and bring the adjustment to TiO 2 Or adjust the thickness of ZnO nano-coating to 10 μm, adjust the color temperature of the light source to 1000K and bake for 10 minutes to complete the first stage of baking; put the adjustmen...

Embodiment 3

[0043] Utilize described baking device to prepare the technology of northern Fujian black tea, realize by following technical measures:

[0044] 1. Put 400kg of Fujian black tea to be baked into the baking tank 1 through the feeding port 5, turn on the rotating shaft 31 to make it rotate, adjust the rotating speed of the rotating shaft 31 to 200rpm, rotate for 6min, and shake the tea leaves. During the baking process Ensure that the tea leaves are fully stir-fried and evenly heated to facilitate baking and improve production efficiency; turn on the heating fan 4, adjust the temperature of the hot air to 275°C, and input hot air into the baking tank 1 to pre-bake the tea leaves for 15 minutes;

[0045] 2. Start the xenon light source system 2 to make the light source warm up and stabilize, and bring the adjustment to TiO 2 Or adjust the thickness of ZnO nano-coating to 20 μm, adjust the color temperature of the light source to 1500K and bake for 15 minutes to complete the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com