Frictional force control based frictional damping type shock absorber

A frictional and frictional force technology, applied in the direction of friction shock absorber, shock absorber, spring/shock absorber, etc., can solve problems such as economic loss and hydraulic rod damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

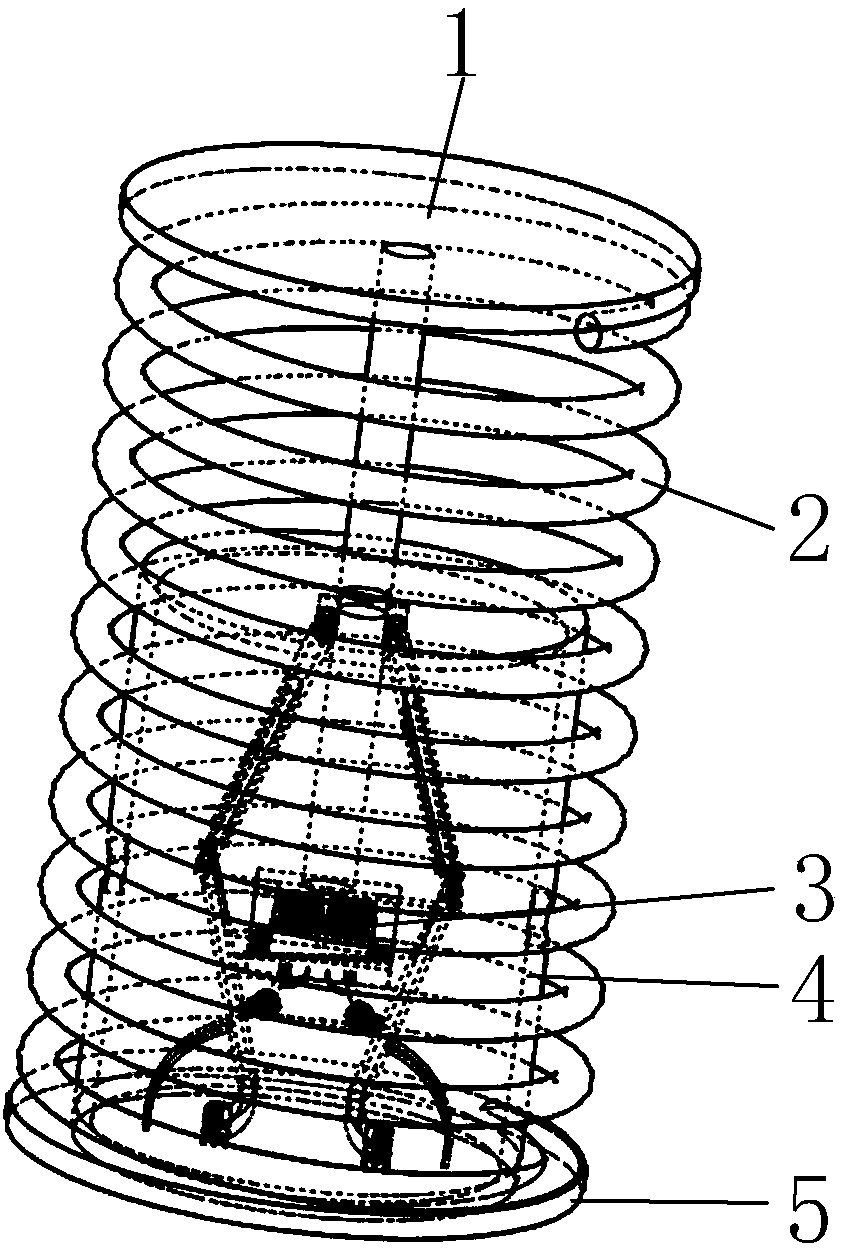

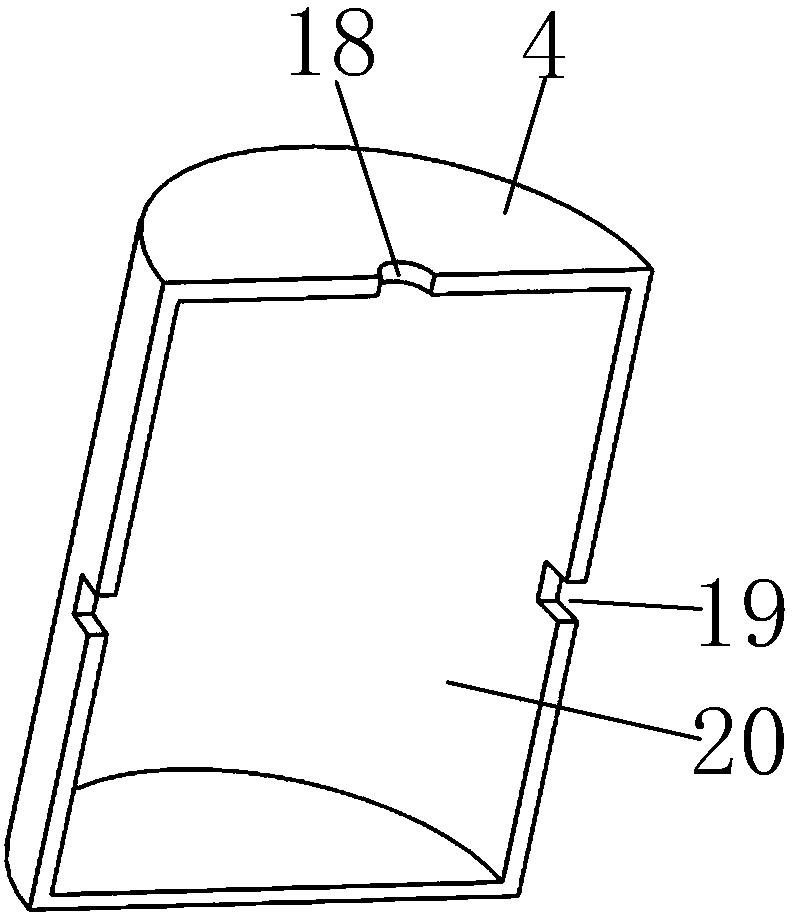

[0055] Such as figure 1 , 2 As shown, it includes a first fixed ring 1, a shock absorbing spring 2, a friction mechanism 3, a shock absorbing sleeve 4, a second fixed ring 5, a connecting rod 6, a telescopic sleeve 7, a telescopic rod 8, a first leaf spring 15, an arc Shaped plate 16, friction plate 17, round hole 18, limit groove 19, accommodation chamber 20, first support 21, second support 23, pushing mechanism 38, fixed cylinder 25, first lug 26, second cylinder Pin 33, the second chute 35, the third cylindrical pin 36, the fourth cylindrical pin 37, the first friction surface 39, such as image 3 As shown, wherein the shock absorber 4 has a housing chamber 20; as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com