Oil-containing-sludge harmless treatment device and method

A technology for harmless treatment of oily sludge, applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of secondary pollution, etc., and achieve good economic benefits and good environmental protection ecology Effective, safe and controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

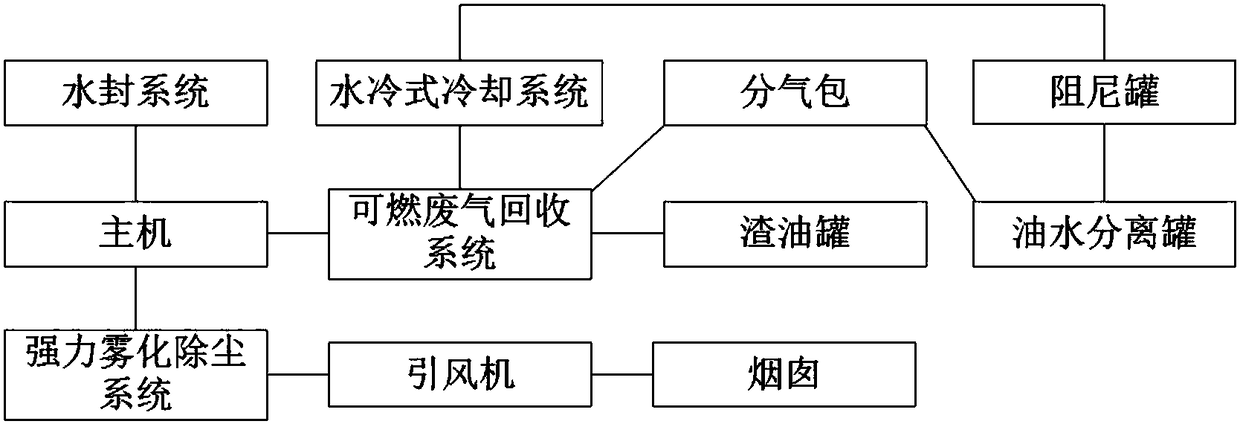

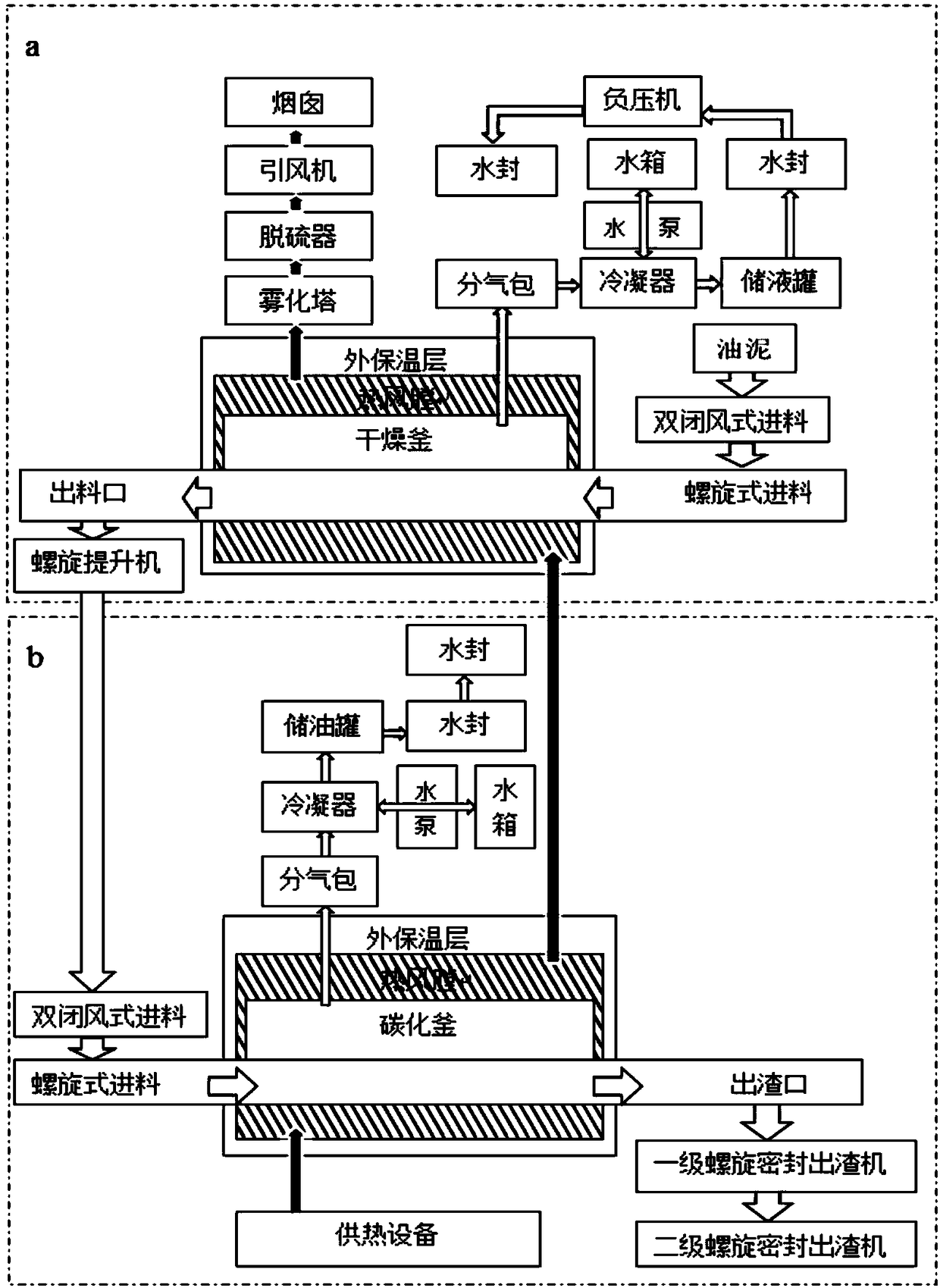

[0016] Such as figure 1 As shown, in the preferred embodiment of the device and method for harmless treatment of oily sludge according to the present invention, the device for harmless treatment of oily sludge includes a host, a gas separator, a residual oil tank, an oil-water separation tank, and a water cooling system. Cooling system, water sealing system, combustible exhaust gas recovery system, powerful atomization dust removal system, induced draft fan, damping tank, and chimney; the main components of the system include raw material dehydration reduction system, drying processor system, and core pyrolysis equipment.

[0017] In a preferred embodiment of the device and method for harmless treatment of oily sludge according to the present invention, the host is connected to a strong atomization dust removal system, the strong atomization dust removal system is connected to the induced draft fan, and the induction A chimney is provided next to the fan. The host is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com