Loading machine with automatic winding and unwinding function

A technology of stripping machine and pay-off device, applied in the field of automatic winding and pay-off stripping machine, can solve the problems of time-consuming and labor-intensive dragging of cables by manpower, inability to synchronise dragging in time, and inability to truly eliminate hidden dangers. The effect of avoiding major safety accidents, reducing workload and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

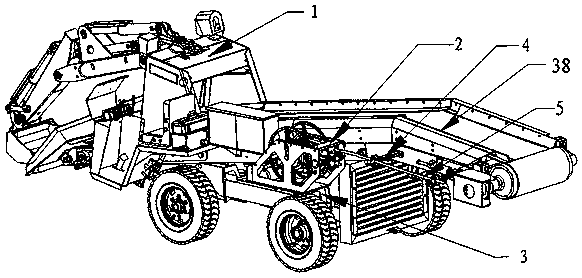

[0020] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, the present invention is equipped with an automatic winding and unwinding device 2 on the machine body 1 through a winding and unwinding device mounting bracket 3. The winding and unwinding device mounting bracket 3 is welded by steel plates, and one end is connected to the stripping machine by connecting bolts. The main body 1 is connected, and the other end is connected with the automatic winding and unwinding device 2 through a connecting bolt.

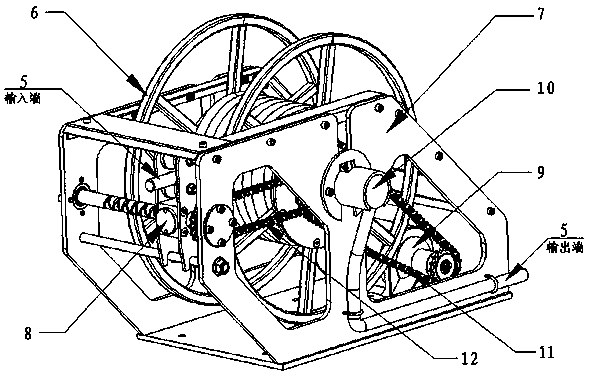

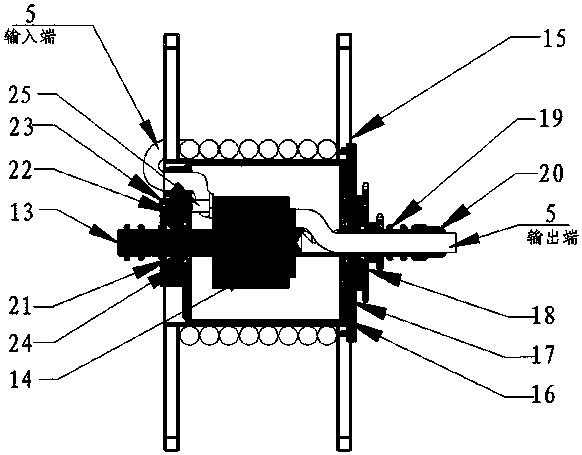

[0021] The cable reel main body 6 of the automatic winding and unwinding device 2 is supported on the reel main body fixing frame 7, and one end of the output part of the power supply cable 5 is connected with the electric control box of the pick-up machine, and the other end is connected with the conductive slip ring 14; the power supply cable 5 is input One end of the part is connected with the conductive slip ring 14, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com