Rice loading and unloading truck

A technology for loading and unloading trucks and rice, which is applied in the directions of loading/unloading, transportation and packaging, etc. It can solve the problems of high physical consumption, consistent speed of harvesters, waste of food, etc., and achieve the effect of flexible turning, low cost and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

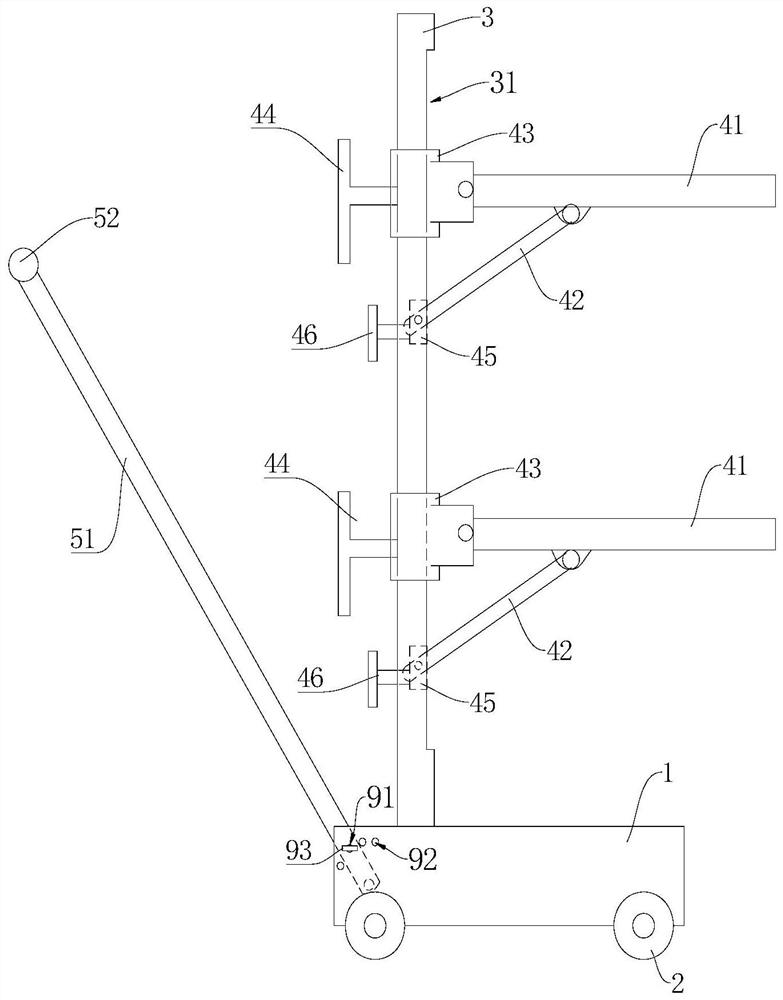

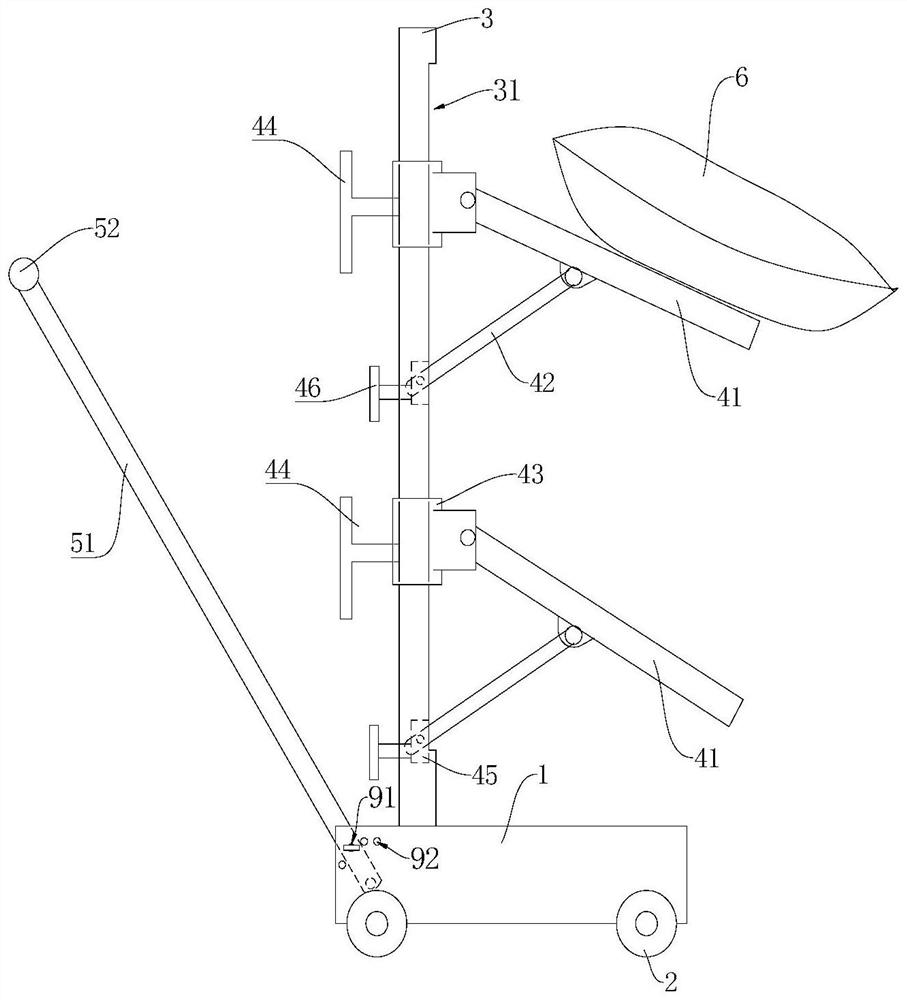

[0025] like figure 1 As shown in the figure, a rice loading and unloading truck includes a cuboid-shaped chassis 1, the chassis 1 is provided with a body, the rear of the chassis 1 is provided with 2 wheels, the front of the chassis 1 is provided with 2 wheels, and the rear of the chassis 1 is provided with two wheels. There is a pusher on the upper part, the pusher is inclined, the pusher includes two struts 51 installed on the chassis 1, the two struts 51 are located on both sides of the chassis 1, and a horizontal pushrod 52 is arranged between the struts 51 on both sides. , There is a rubber sleeve on the push rod, which can increase the friction force.

[0026] In this embodiment, the pusher is hinged to the chassis 1, and the chassis 1 is provided with an angle adjusting device for adjusting the inclination of the pusher. The adjusting device includes a positioning pin 93 , a first positioning hole 91 is provided in the lower part of the support rod 51 , and a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com