A workshop material transport vehicle

A technology for transporting vehicles and materials, applied in the field of temporary material transporting devices, can solve the problems of different orientation, single function, inconvenient loading and unloading by workers, etc., and achieve the effects of convenient operation, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

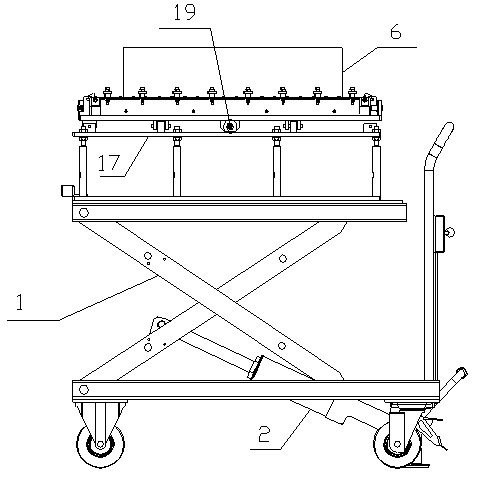

[0028] like figure 1 , 2 . As shown in 3, a workshop material transport vehicle includes a frame body 1, the frame body is a scissor lift device driven by a foot jack 2, and the lifting of the frame body is controlled by the foot jack to adapt to different heights Requirements, the frame body is provided with a rotating plate 3 that can rotate horizontally relative to the frame body, and the rotating plate is used to adjust the orientation of the material.

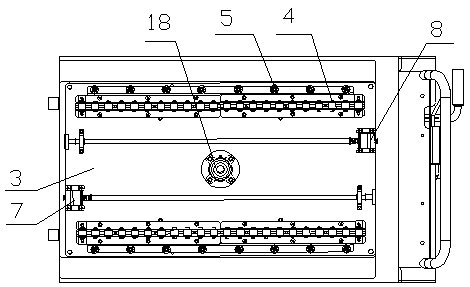

[0029] A bearing rail is arranged on the rotating plate, a horizontal axis guide wheel 4 is arranged on the bearing rail, and a vertical axis guide wheel 5 is arranged on the side of the bearing rail. The bearing rail is suitable for preventing materials with regular shapes, such as boxes 6 filled with materials or materials with regular shapes (such as plates) that are arranged in an array, and the horizontal axis guide wheels reduce the movement of the boxes on the bearing rails. Frictional resistance, the vertical axi...

Embodiment 2

[0035] like Figure 5 , 6 As shown, the difference from Embodiment 1 is that the upper end of the vertical shaft passes through the rotating plate, the upper end of the vertical shaft is provided with a gear, and the two control rods are provided with racks that cooperate with the gear. With the rotation of the rotating plate, the control rod moves relative to the rotating plate under the action of the gear, so as to realize the opening and closing control of the limit block. For example, the tooth pitch of the meshing can be designed so that when the rotating plate rotates 90 degrees, the limit block is fully opened, so that the limit block is in a clamped state when the transport vehicle moves forward, the transport vehicle stops, and the rotating plate is rotated 90 degrees. The limit block is fully opened, which is convenient for unloading materials on the side of the transport vehicle without changing the direction of the transport vehicle.

[0036] The vertical shaft i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com