Press-fit type steel ring production process

A production process and press-fit technology, which is applied in the field of press-fit solid tire accessories, can solve the problems of strict product standards, backwardness, and high production process control requirements, and achieve good continuity of blank quality, reduce costs, and process The effect of fewer nodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

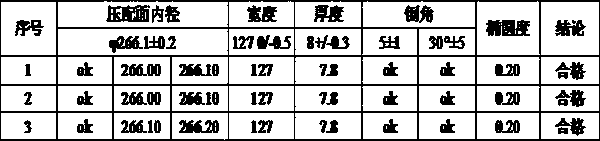

[0093] To produce 5×5-inch press-fit steel rings, first determine the value of the material reduction coefficient G for blanking.

[0094] The specific steps will not be stated again, L1 is 200mm, L2 is 200mm, L3 is 393mm, and the value of G1 is 7mm; L1' is 200mm, L2' is 200mm, L3' is 391mm, and the value of G2 is 9mm; then the calculation is as follows The material reduction coefficient G of the material is 8mm,

[0095] Verify material reduction factor G:

[0096] The standard diameter DB of the finished product used in the test is 126.5±0.2mm, and ±0.2mm is the allowable error range according to the standard requirements. Calculated to get DY129mm, DY'130.3mm, so the value of the material reduction coefficient G is 8mm to meet the requirements.

[0097] The internal diameter D of the press-fit surface of the standard product is 126.5mm, the standard thickness T of the material is 8mm, the subtraction coefficient G of the substituting material is 8mm, and the width W of th...

Embodiment 2

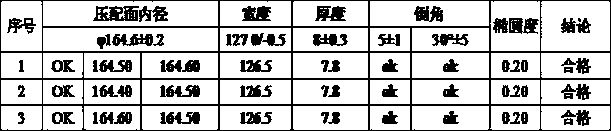

[0104] To produce a 5×6.5-inch press-fit steel ring, first determine the value of the material reduction coefficient G for blanking.

[0105]The specific steps will not be stated again, L1 is 200mm, L2 is 200mm, L3 is 393mm, and the value of G1 is 7mm; L1' is 200mm, L2' is 200mm, L3' is 391mm, and the value of G2 is 9mm; then the calculation is as follows The material reduction coefficient G of the material is 8mm,

[0106] Verify material reduction factor G:

[0107] The standard diameter DB of the finished product used in the test is 164.6±0.2mm, and ±0.2mm is the allowable error range according to the standard requirements. Calculated to get DY167.89mm, DY'169.53mm, so the value of material reduction coefficient G is 8mm to meet the requirements.

[0108] The internal diameter D of the press-fit surface of the standard product is 164.6mm, the standard thickness T of the material is 8mm, the subtraction coefficient G of the substituting material is 8mm, and the width W of ...

Embodiment 3

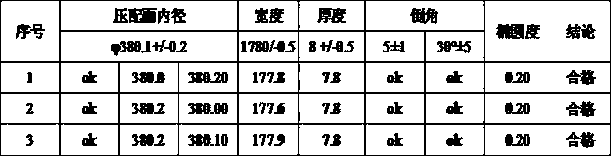

[0115] To produce a 5.5×8-inch press-fit steel ring, first determine the value of the material reduction coefficient G for blanking.

[0116] The specific steps will not be stated again, L1 is 200mm, L2 is 200mm, L3 is 393mm, and the value of G1 is 7mm; L1' is 200mm, L2' is 200mm, L3' is 391mm, and the value of G2 is 9mm; then the calculation is as follows The material reduction coefficient G of the material is 8mm,

[0117] Verify material reduction factor G:

[0118] The standard diameter DB of the finished product used in the test is 202.7±0.2mm, and ±0.2mm is the allowable error range according to the standard requirements. Calculated to get DY206.75mm, DY'208.78mm, so the value of the material reduction coefficient G is 8mm to meet the requirements.

[0119] The internal diameter D of the press-fit surface of the standard product is 202.7mm, the standard thickness T of the material is 8mm, the subtraction coefficient G of the substituting material is 8mm, and the width ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com