Variable-diameter threaded milling cutter

A variable-diameter thread and milling cutter technology, which is applied in the direction of thread cutting tools, metal processing equipment, tangent devices, etc., can solve the problems of fixed working length, non-variable diameter, inconvenient and fast assembly or disassembly, etc., to achieve connection flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

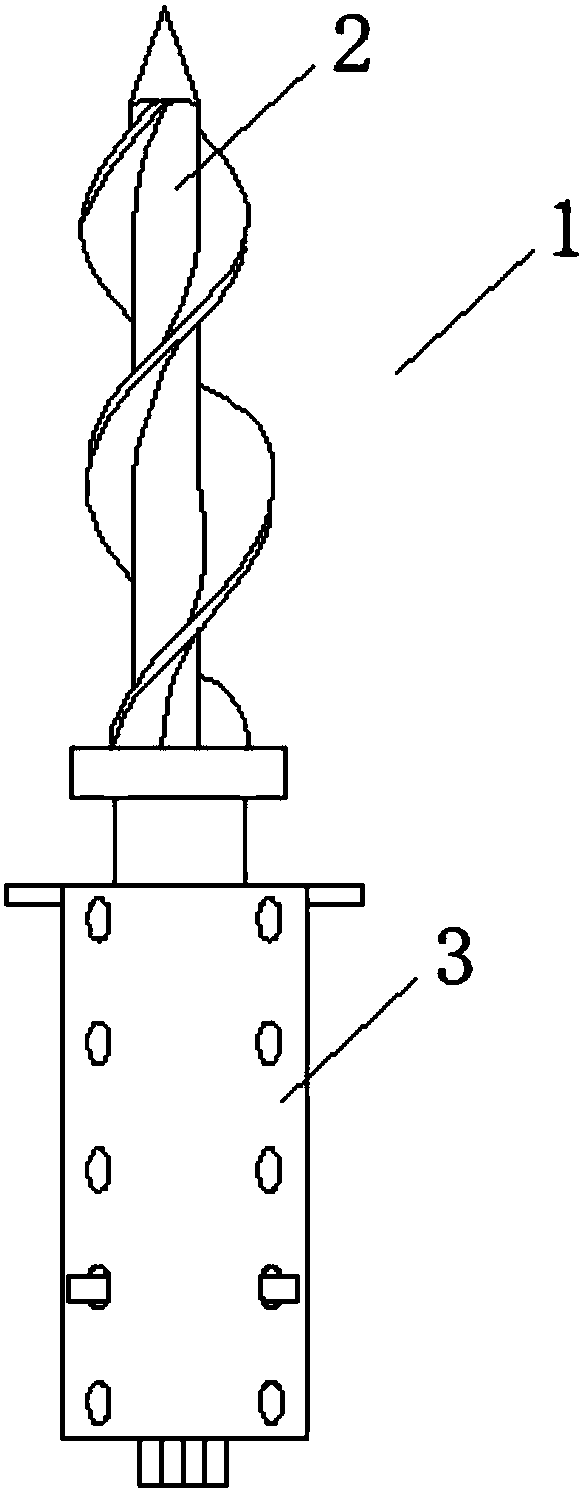

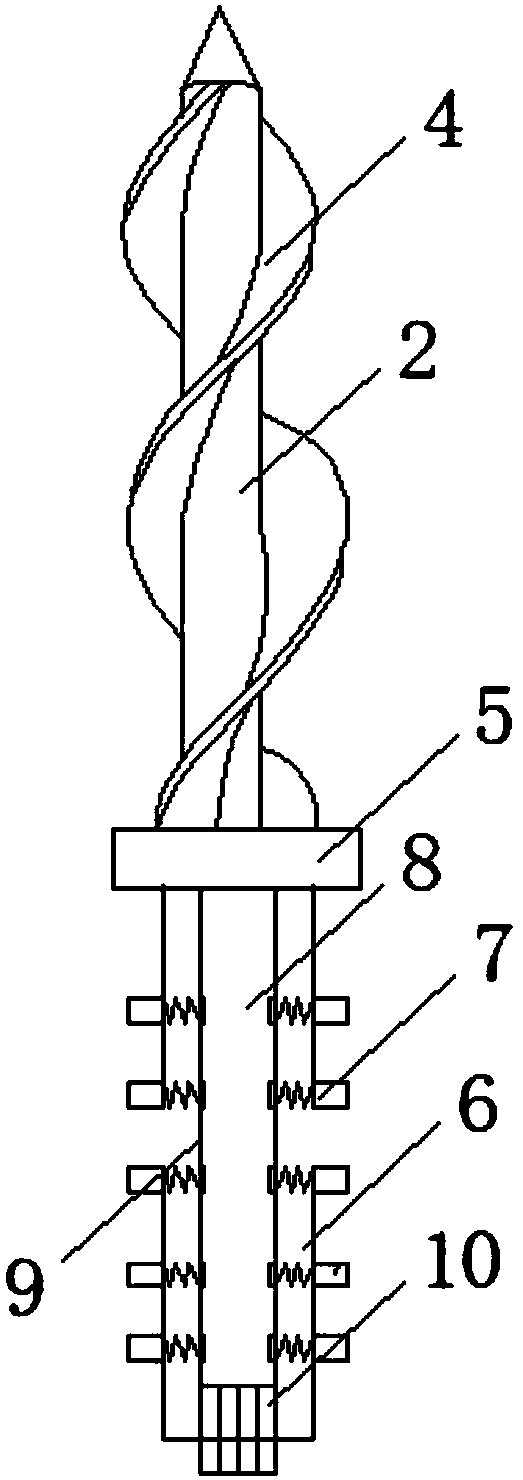

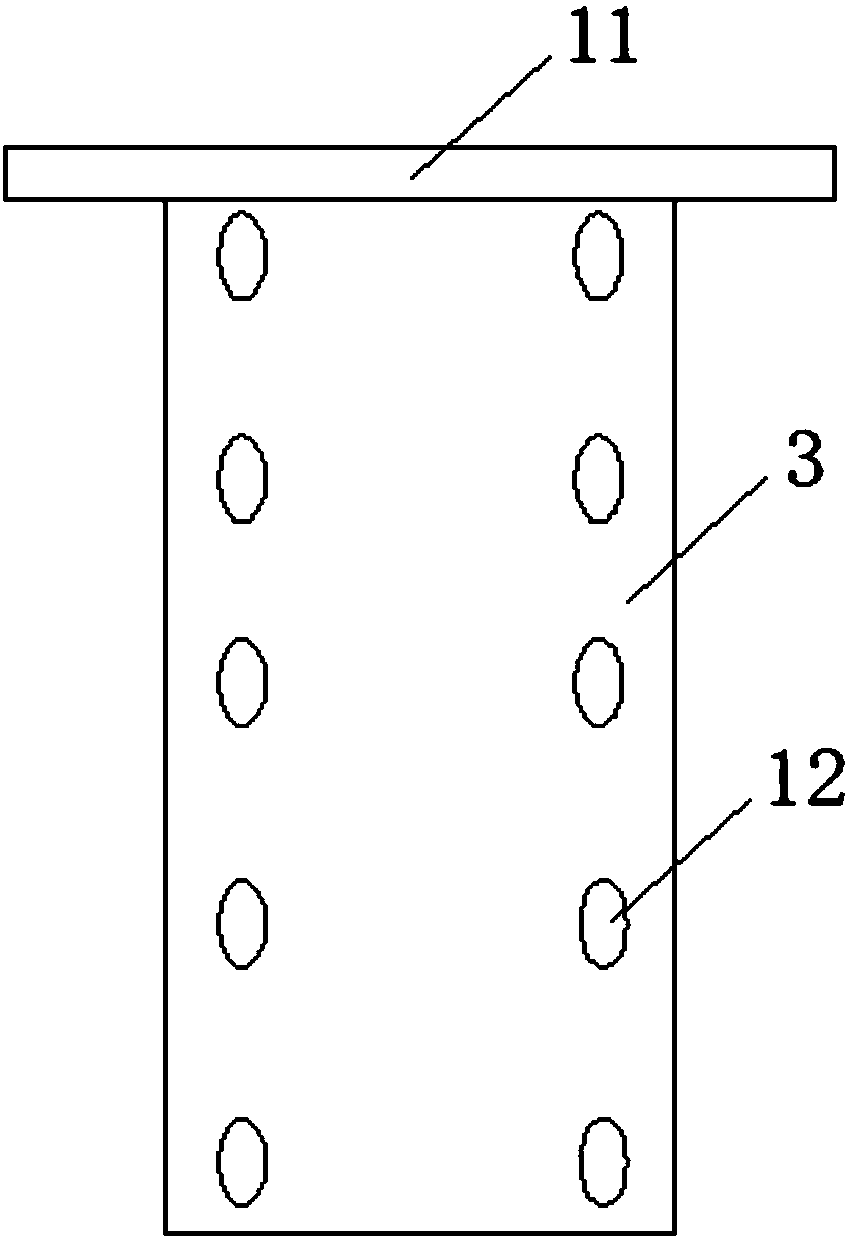

[0021] see Figure 1-5 As shown, a variable-diameter thread milling cutter includes a cutter body 1, a handle 2 and a sleeve 3. A sleeve 3 is installed below the cutter body 1, and a cutter body 1 and a handle 2 are installed above the sleeve 3. Screw blade 4 is arranged above, and retaining ring 5 is arranged in the middle of knife handle 2, mounting column 6 is arranged below retaining ring 5, and clamping blocks 7 are arranged at both ends of mounting column 6 at equal intervals, and rotating rod is arranged inside mounting column 6 8. A supporting ring 11 is arranged on the top of the sleeve 3, and the retaining ring 5 is blocked by the supporting ring 11, and several sockets 12 are arranged at equal intervals at both ends of the side wall of the sleeve 3.

Embodiment 2

[0023] In addition, please continue to Figure 1-5 As shown, the difference between it and the above-mentioned embodiment is that: the rod mounting ring 9 matching the rotating rod 8 is arranged inside the mounting column 6, and the bottom of the rotating rod 8 is provided with a transmission gear 10, which is connected to the moving coil of the motor through the transmission gear 10 , the motor drives the tool handle 2 to rotate through the transmission gear, and the screw blade 4 on the tool handle 2 is used to drill out the threads of the parts. Inside the sleeve 3 is provided a through ring 13 that matches the post 6 , and several clamping blocks 7 are matched with several insertion holes 12 . A plug 14 is provided at one end of several clamping blocks 7 , and a spring 15 is provided at one side of the plug 14 , and a welding rod 16 is provided at one side of the spring 15 . The screw blade 4 is a helical stacked structure, and one end of the handle 2 is a conical structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com