Detecting method and device for blocked hole of dust collector and dust collector

A detection method and technology for vacuum cleaners, applied in the installation of vacuum cleaners, measuring devices, electrical equipment, etc., can solve the problems of low reliability of hole blocking detection, and achieve the effects of improving reliability, improving service life and accurate protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

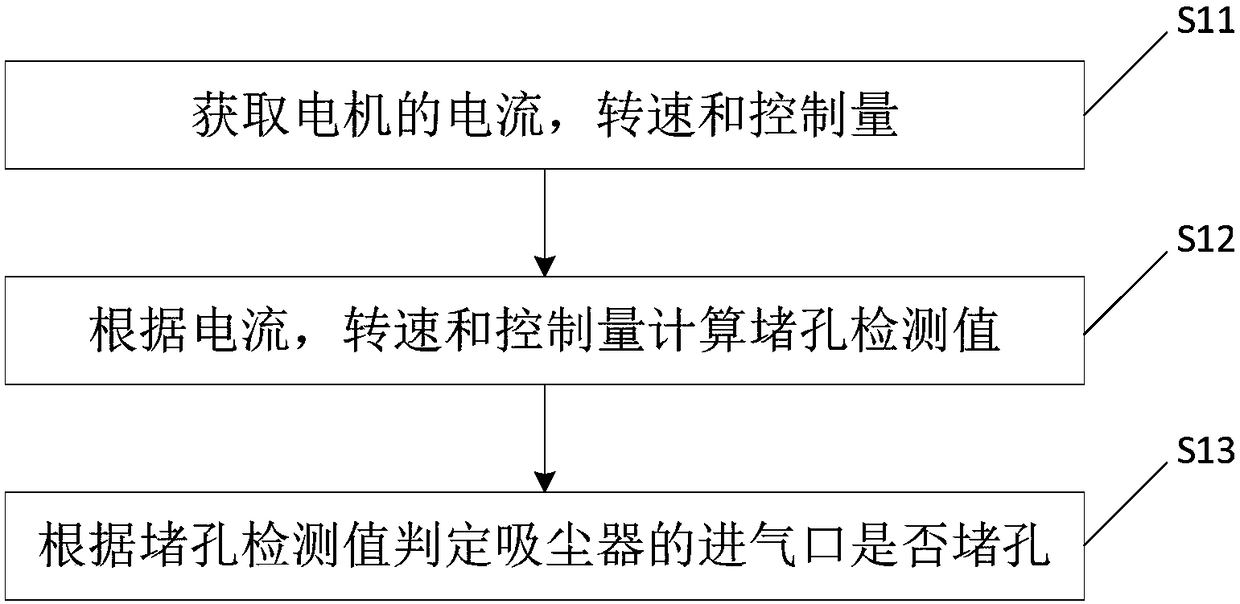

[0054] This embodiment provides a method for detecting hole plugging of a vacuum cleaner, which can be used in a detection device for hole plugging of a vacuum cleaner, such as figure 1 As shown, the method includes the following steps:

[0055] S11. Obtain the current, rotational speed and control quantity of the motor, wherein the control quantity is used to adjust the rotational speed of the motor.

[0056] During the working process of the vacuum cleaner, the detection device for the blocked hole of the vacuum cleaner obtains the current, speed and control amount of the motor in real time. Wherein, the control amount can be obtained by adjusting the difference between the current of the motor and the preset current (for example, it can be PI adjustment, or PID adjustment, or PWM modulation).

[0057] Specifically, the current of the motor can be measured with a clamp ammeter, and the rotational speed of the motor can be measured with a sensor.

[0058] S12, calculating a...

Embodiment 2

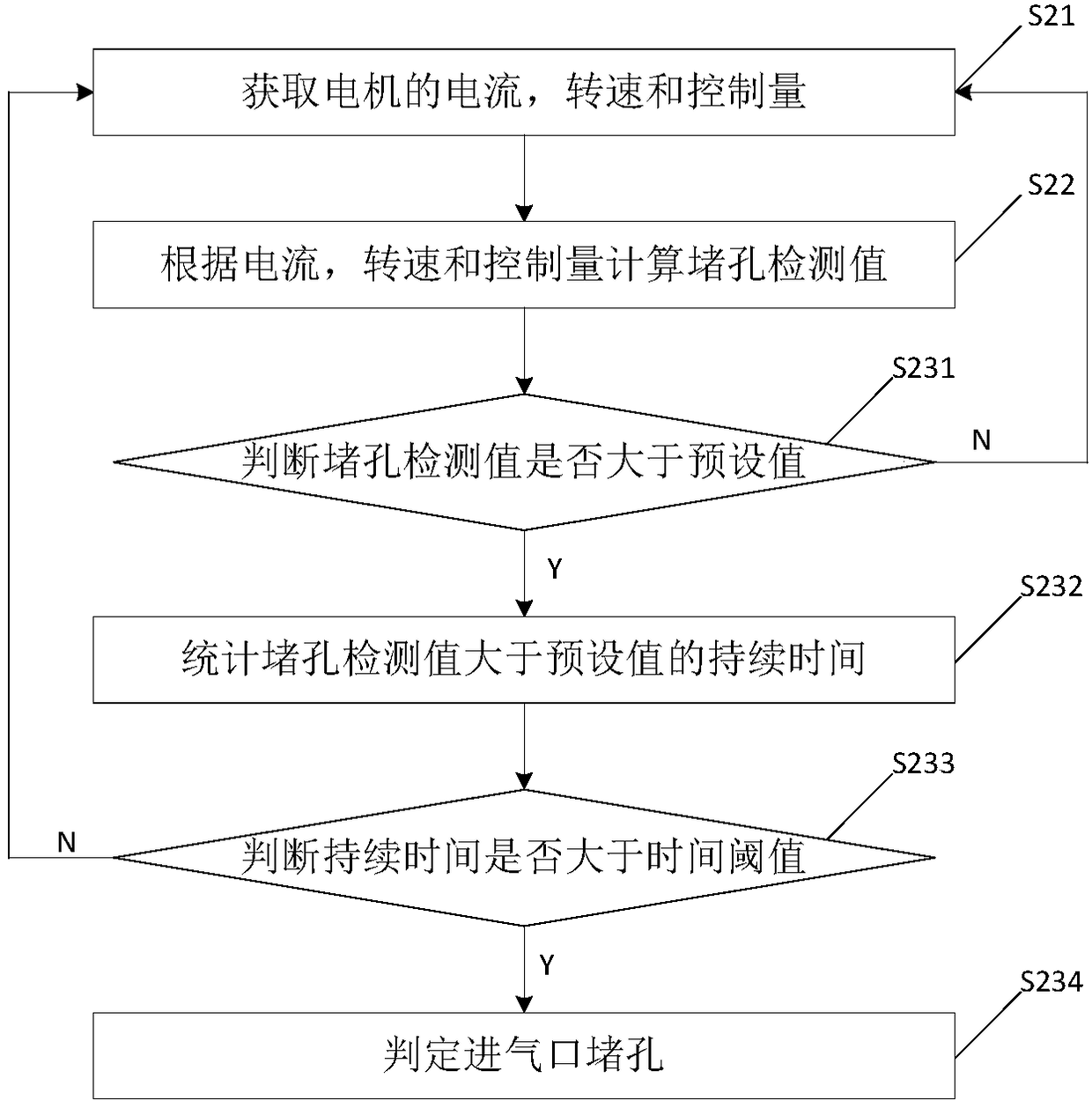

[0064] This embodiment provides a method for detecting hole plugging of a vacuum cleaner, which can be used in a detection device for hole plugging of a vacuum cleaner, such as figure 2 As shown, the method includes the following steps:

[0065] S21. Obtain the current, rotational speed and control amount of the motor, wherein the control amount is used to adjust the rotational speed of the motor.

[0066] It is the same as step S11 in Embodiment 1, and will not be repeated here.

[0067] S22, calculating a blocked hole detection value according to the current, the rotational speed and the control amount.

[0068] When the detection device for the hole blocking of the vacuum cleaner calculates the detection value of the hole blocking, the following formula can be used for calculation:

[0069]

[0070] Wherein, A is the detection value of the blocked hole; n is the rotating speed; i 1 Is the current; D is the control amount.

[0071] In addition, when the motor is a br...

Embodiment 3

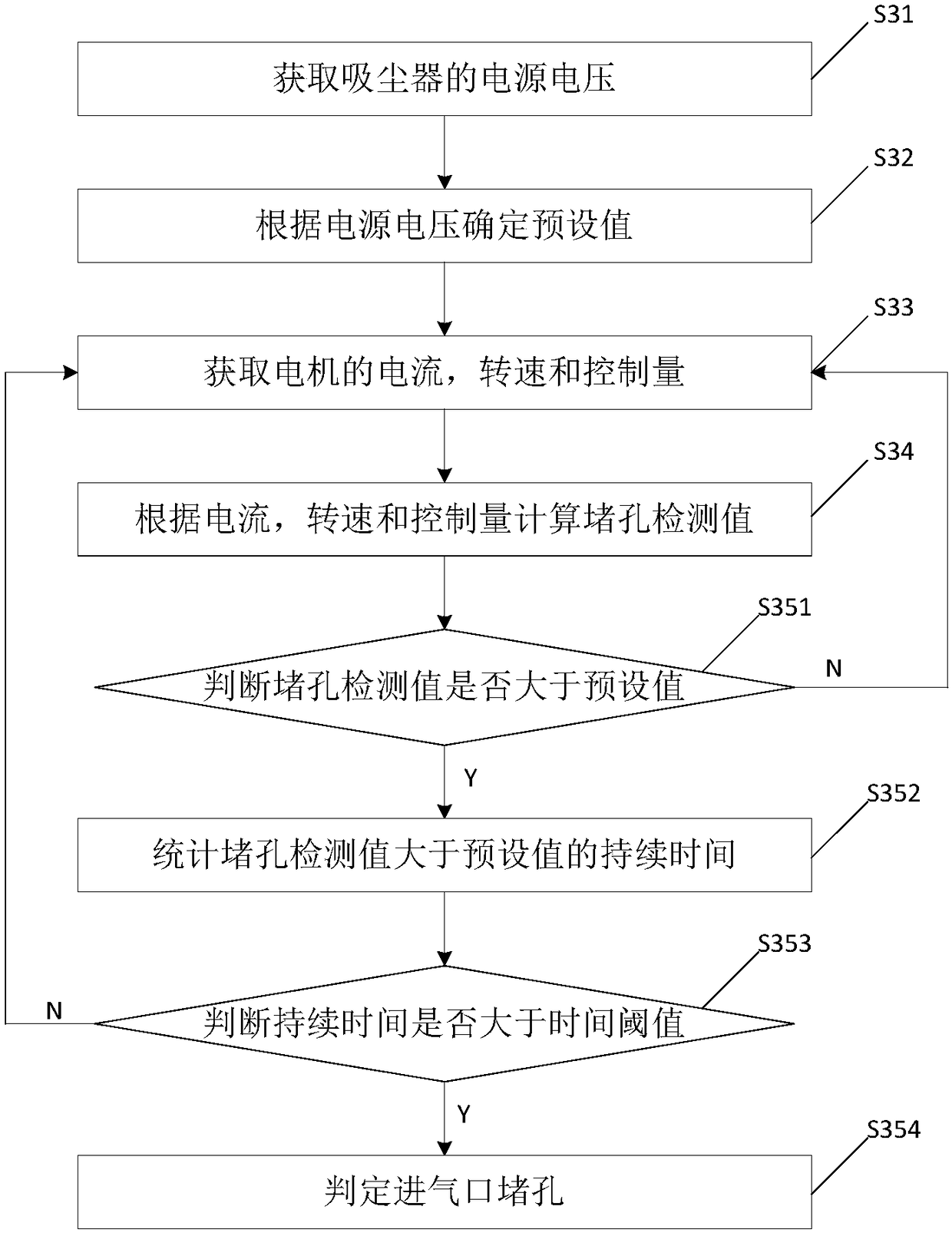

[0086] This embodiment provides a method for detecting hole plugging of a vacuum cleaner, which can be used in a detection device for hole plugging of a vacuum cleaner, such as image 3 As shown, the method includes the following steps:

[0087] S31. Obtain the power supply voltage of the vacuum cleaner.

[0088] The power supply voltage of the vacuum cleaner can be divided into two types, one is for the rechargeable vacuum cleaner, the power supply voltage of the vacuum cleaner is gradually reduced during the working process of the vacuum cleaner; The external power supply (usually the mains) is connected, and the power supply voltage generally remains unchanged.

[0089] Therefore, when the vacuum cleaner is working, the detection device for hole blocking of the vacuum cleaner measures its power supply voltage in real time, which is used to determine the specific size of the preset value when the hole blocking detection value is compared with the preset value.

[0090] S32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com