Plastic packaged quartz crystal resonator and preparation method thereof

A quartz crystal and plastic packaging technology, applied in electrical components, impedance networks, etc., can solve the problems of reduced production efficiency and product yield, high manufacturing costs, and inability to meet market demands, achieving high flexibility and reduced electroplating area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

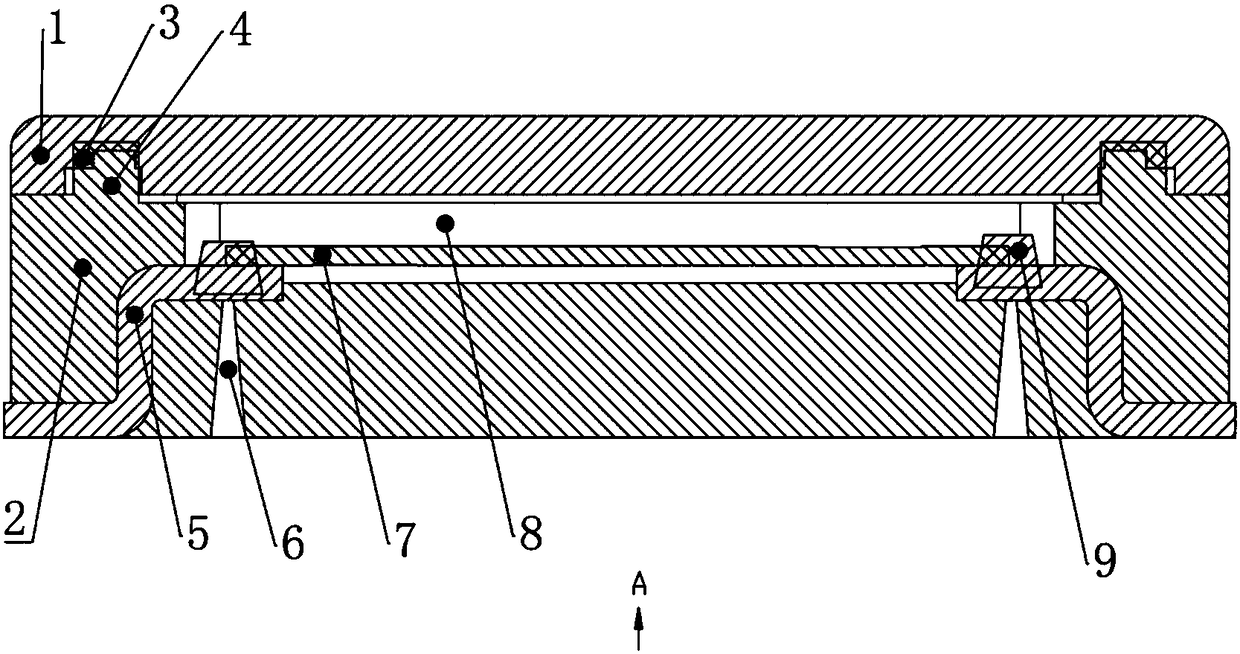

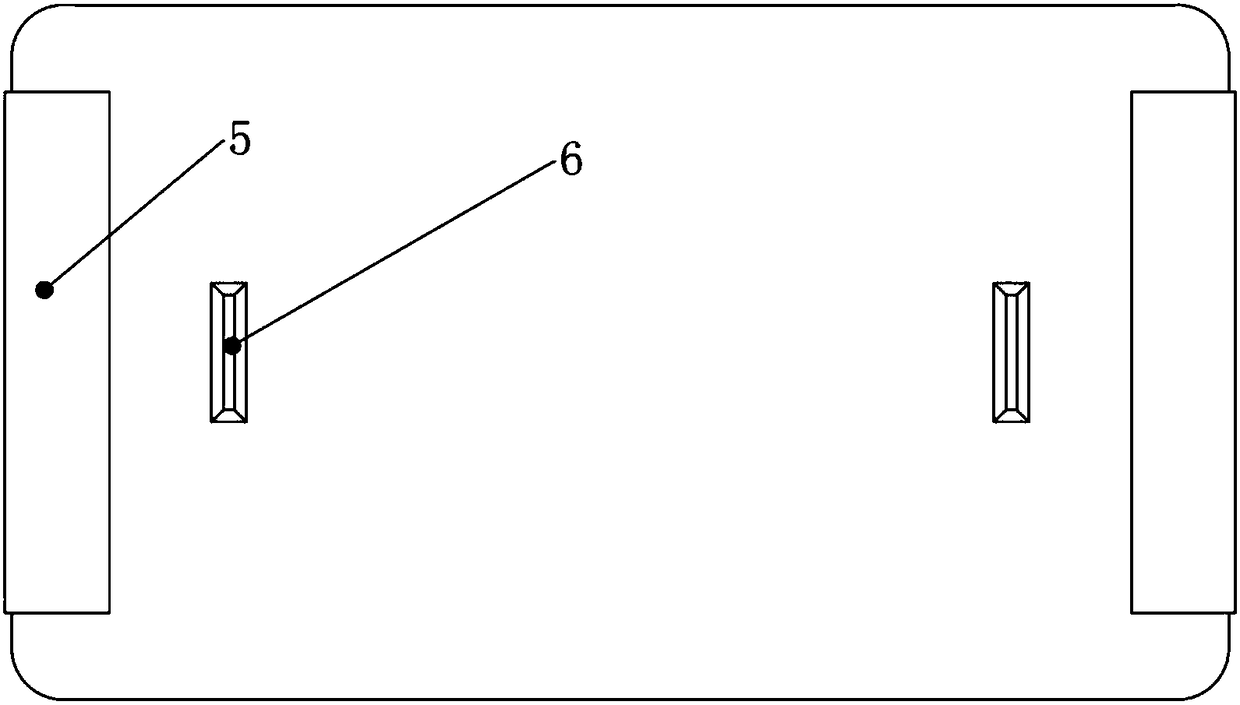

[0039] Such as figure 1 and 2As shown, a plastic-encapsulated quartz crystal resonator includes a cover plate 1, a quartz wafer 7, a conductive glue 9 and a base 2. The cover plate 1 is a translucent plastic cover plate formed by injection molding, and the cover plate 1 is provided with a groove 3 for accommodating the protrusion 4 on the base 2, the quartz wafer 7 is an electrode-plated quartz wafer 7, the base 2 includes an opaque plastic body and conductive pins, the An accommodating chamber 8 for containing a quartz wafer 7 and a protrusion 4 corresponding to the groove 3 are arranged on the opaque plastic body, and the conductive pins are combined with the opaque plastic body through a nano-injection molding process, so The above-mentioned quartz wafer 7 plated with electrodes is cured in the accommodation chamber 8 through conductive glue 9 and connected to the conductive pins. The cover plate 1 and base 2 are fixed together to seal the quartz wafer 7 .

[0040] The co...

Embodiment 2

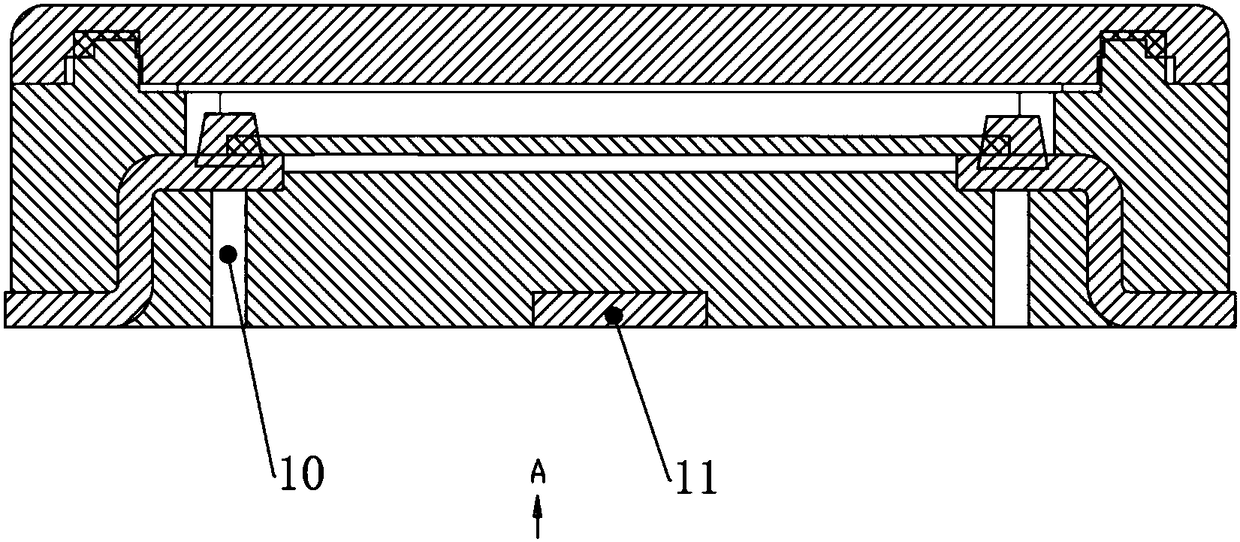

[0043] Such as image 3 and 4 As shown, it is basically the same as Embodiment 1, the difference is that the crystal resonator is a three-pin quartz crystal resonator, and the three-pin quartz crystal resonator also includes a ground pin 11, and the ground pin 11 is arranged on three pin middle of the quartz crystal resonator. The power connection pin is a Z-shaped pin 5, and an injection hole is provided on the opaque plastic body corresponding to the Z-shaped pin 5. Setting the injection hole can ensure that the metal will not be deformed by the impact force of the plastic during injection molding, which can effectively improve product quality and yield. The injection holes can be set in different shapes as required, and square holes 10 are used in this embodiment.

Embodiment 3

[0045] Such as Figure 5 and 6 As shown, it is basically the same as Embodiment 1, the difference is that the crystal resonator is a four-pin quartz crystal resonator, and the four-pin quartz crystal resonator includes two power-connecting pins and two grounding pins Pin 11, the described electrical connection pins and grounding pins 11 are alternately arranged at the four corners of the four-pin quartz crystal resonator, and the described electrical connection pins can be in any shape, and the present embodiment is a square lead Feet 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com