Scramjet engine and its combustion chamber based on high repetition rate laser

A scramjet, high repetition frequency technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problem of small flame stabilization range, inability to effectively stabilize large-area flames, and the ability of the fire core to resist turbulent dissipation. To avoid energy loss, avoid electromagnetic interference problems, and promote development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

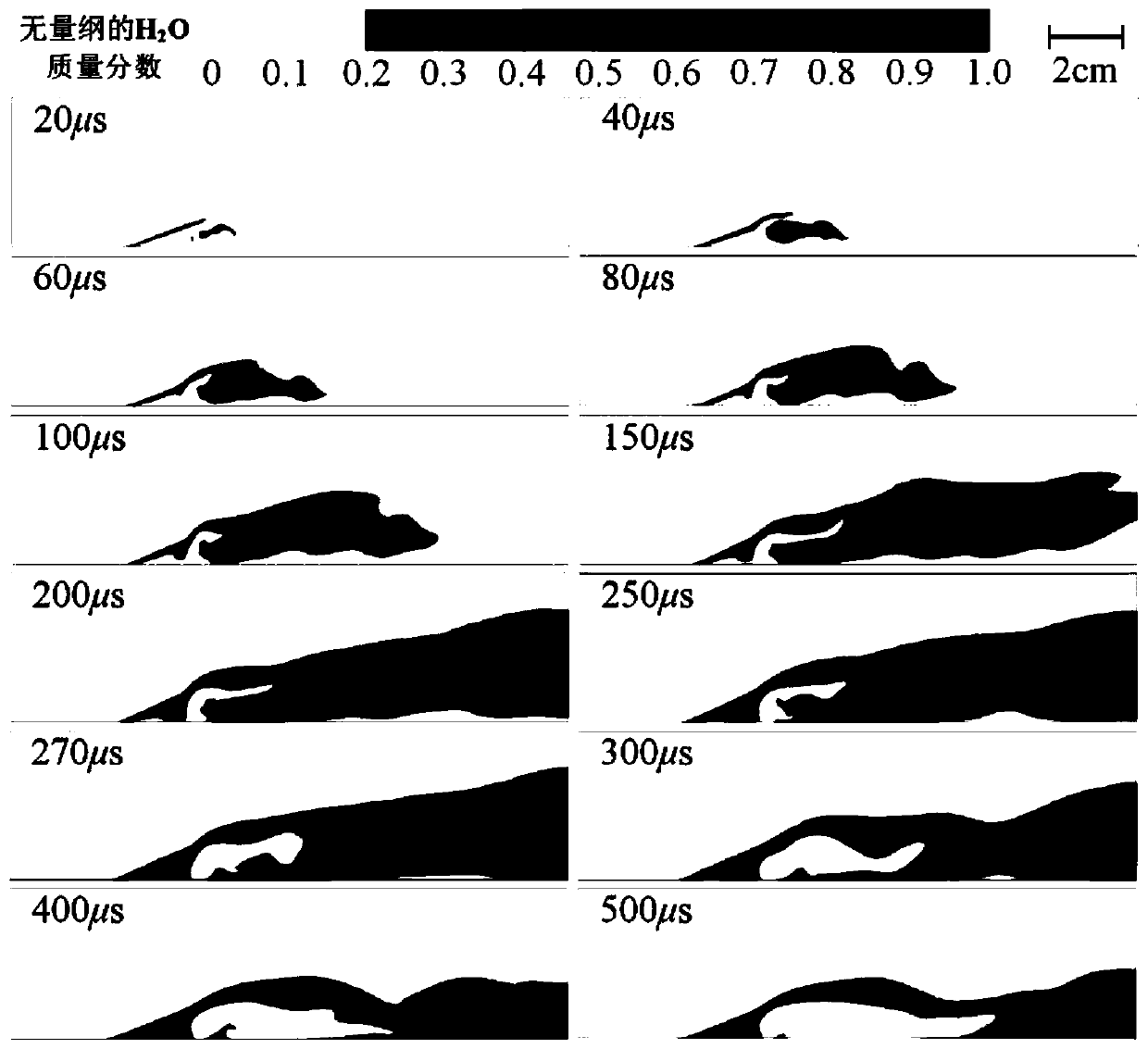

[0021] The accompanying drawings constituting a part of this application are used to provide further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

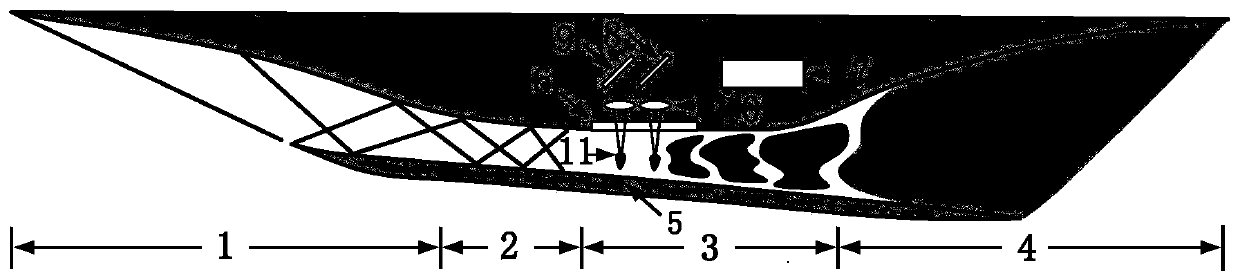

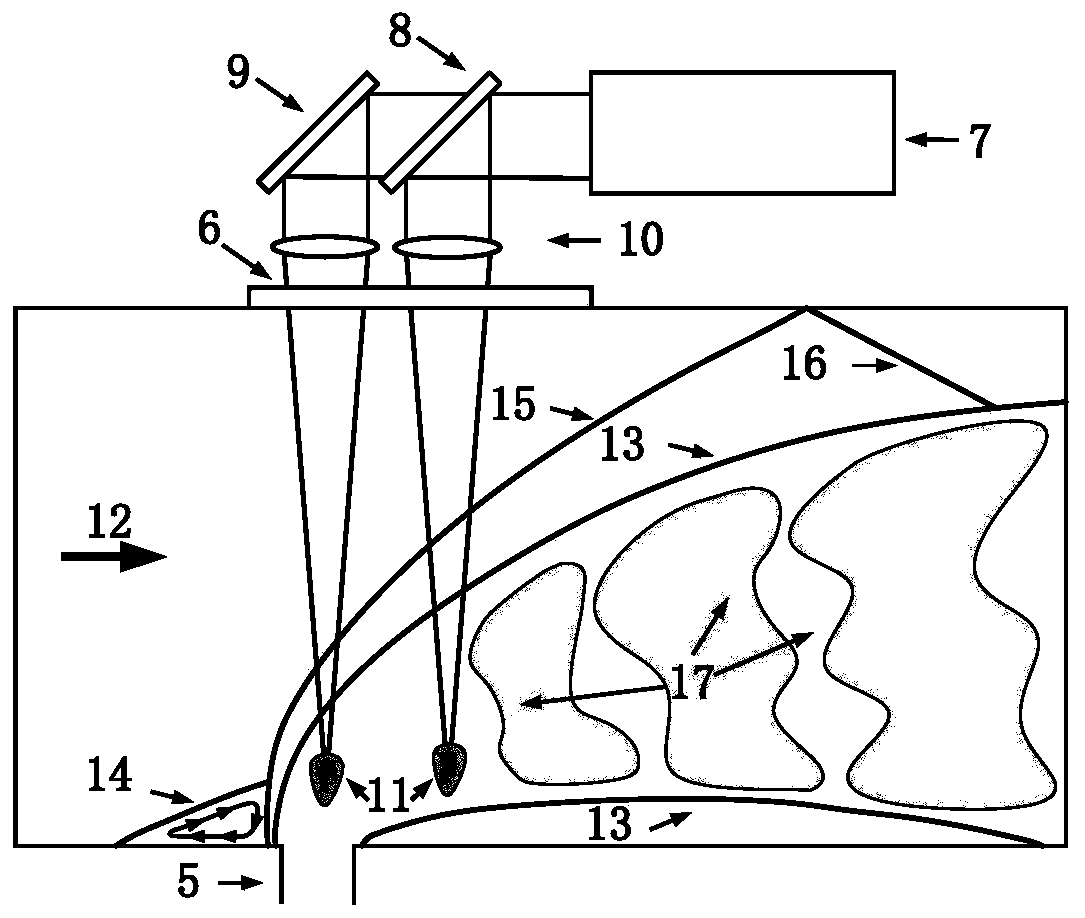

[0022] see figure 1 , the combustion chamber 3 based on the high repetition frequency laser provided by the present invention includes a cavity. The side wall of the cavity is provided with a window 6 that can only pass through the pulse laser, and a convex lens 10 and a laser 7 capable of generating high repetition frequency laser pulses are arranged outside the cavity facing the window 6 . The generated pulsed laser is focused by the convex lens 10 to induce plasma in the cavity to form an initial fire core 11 .

[0023] High-repetition-frequency laser pulses can be used as an energy source to induce plasma and shock waves. The laser 7 here can be a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com