Traction sliding system and construction technology for erecting prefabricated crane beam in power plant

A crane beam and sliding technology, which is applied in the field of traction sliding system and construction technology, can solve the problems affecting the construction, unable to complete the erection of the crane beam on schedule, and limited lifting capacity, so as to achieve the effect of guaranteeing the lifting capacity of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

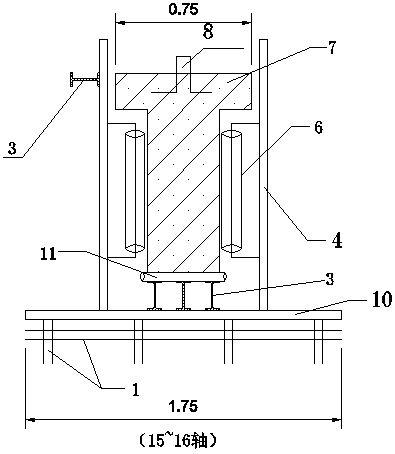

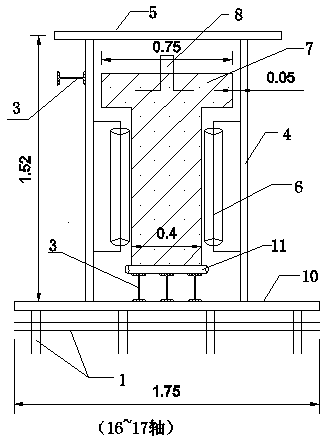

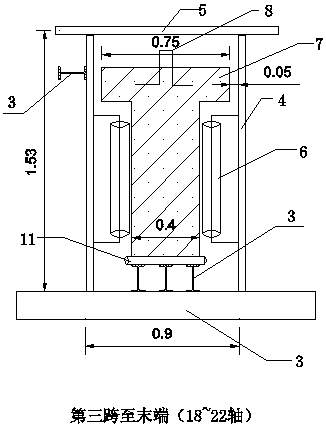

[0037] A traction-sliding system erected by a prefabricated crane beam in a power plant, such as figure 1 , 2, 3, 4, 5, and 6, the first span to the third span of the crane girder are on both sides of the platform in the installation room, and the sliding system includes the supporting sliding unit and the crane girder erected on the first span and the second span of the crane girder The sliding unit built from the third span to the end; the supporting sliding unit and the sliding unit both include a bottom foundation, a beam body placement platform 12 and a guiding and stabilizing structure arranged on the bottom foundation, and the bottom foundation supporting the sliding unit includes a supporting platform Scaffolding 1 and the operating platform scaffolding 2 separately erected on the outside of the supporting platform scaffolding, the bottom foundation of the sliding platform is the pre-embedded steel plate 15 on the clear span side of the corbel; The channel steel verti...

Embodiment 2

[0044] A construction process of a traction-sliding system for erecting prefabricated crane beams in a power plant. The traction-sliding system in the construction process is the traction-sliding system in Embodiment 1, and the system will not be described in detail here. This construction technique is used in erecting the prefabricated beams of the powerhouse of Shangmaxiangdi A Hydropower Station. The project overview is as follows:

[0045] The Shangmasangdi A Hydropower Station is located on the upper reaches of the Masangdi River in the Gandaki area of western Nepal. It is a runoff water diversion hub project mainly for power generation, with a control basin area of 2,740km2. composed of buildings. Two mixed-flow units are installed in the factory building, with an installed capacity of 2×25MW. The main factory building has three floors; the auxiliary factory buildings are arranged on the upstream side of the main factory building and the factory area on the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com