Method for preparing p-tert-butylbenzaldehyde by carrying out liquid phase oxidation on p-tert-butyltoluene

A technology of p-tert-butyltoluene and p-tert-butyl, which is applied in the chemical field, can solve problems such as affecting mass transfer, increasing equipment investment, and hidden safety hazards, achieving the effects of mild reaction conditions, reducing investment costs, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

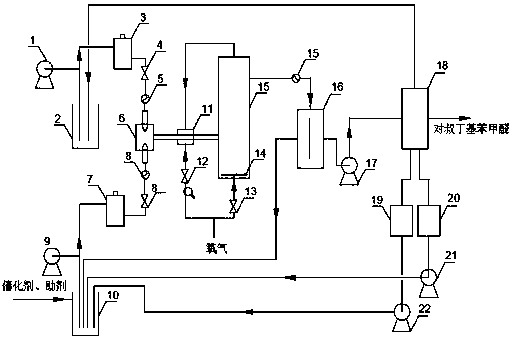

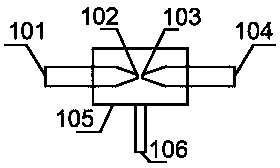

[0034] Weigh 1.48 kg of p-tert-butyl toluene and place it in a raw material storage tank, weigh 1.41 kg of water, 0.007 kg of p-tert-butyl benzoate, 0.063 kg of tert-butyl benzyl alcohol, 15 mg of auxiliary agent, 15 mg of catalyst, and over Sodium oxycarbonate 0.0015 kg is dissolved in the solvent storage tank, wherein the additives are 10 mg of sodium p-tert-butylbenzoate and 5 mg of sodium dodecylbenzenesulfonate, and the catalyst is benzopyrimidine cobalt complex, through the corresponding metering pump Transport to the corresponding storage tank, heat up to 40°C through the heat exchanger, the two fluids collide in the impingement flow reactor, and the micron-sized emulsion produced is transported to the bubble column reactor through the ejector, and the ejector entrains and bubbles Oxygen and fresh oxygen at the top of the reactor are oxidized in the bubble column reactor, and oxygen is delivered to the bubble reactor through the gas distributor to ensure the reaction for...

Embodiment 2

[0036] Take by weighing 1065g of p-tert-butyl toluene and place it in a raw material storage tank, weigh 7.1 kg of water, 460 g of p-tert-butyl benzoate, 1.42 kg of p-tert-butyl benzyl alcohol, 0.4 g of auxiliary agent, 0.4 g of catalyst, and over Sodium oxycarbonate 480g is dissolved in the solvent storage tank, wherein additives are 0.1 g of sodium p-tert-butylbenzoate, 0.1 g of potassium p-tert-butylbenzoate and 0.2 g of heavy alkylbenzene sulfonate, and the catalyst is nickel benzopyrazole 0.2 g of the complex and 0.2 g of the benzopyridine vanadium complex were transported to the corresponding storage tank through the corresponding metering pump, and the temperature was raised to 80°C through the heat exchanger, and the two fluids collided in the impinging flow reactor, resulting in The micron-sized emulsion is transported to the bubble column reactor through the ejector, and the oxygen and fresh oxygen at the top of the bubble reactor are entrained by the ejector, and the...

Embodiment 3

[0038] Take by weighing 1.48 kg of p-tert-butyltoluene and place it in a raw material storage tank, weigh 9.99 kg of water, 1.131 kg of p-tert-butyl benzoate, 114 g of p-tert-butyl benzyl alcohol, 0.103 g of auxiliary agent, 0.5 g of catalyst, and pro-oxidant Sodium percarbonate 0.069 kg is dissolved in the solvent storage tank, wherein the additives are 0.05 g of lithium p-tert-butylbenzoate, 0.0.5 g of potassium p-tert-butylbenzoate and 0.003 g of heavy alkylbenzenesulfonate, and the catalyst is 0.2 g of benzopyrazole aluminum complex and 0.3 g of benzopyridine copper complex are transported to the corresponding storage tank through the corresponding metering pump, and the temperature is raised to 60 °C through the heat exchanger. Internal collision, the micron-sized emulsion produced is transported to the bubble column reactor through the injector, and the injector entrains the oxygen and fresh oxygen at the top of the bubble reactor, and the oxidation reaction is carried ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com