Automatic extruder filter screen replacing device capable of keeping continuous material flow

A technology of automatic replacement and filter screen, applied in the field of extruder, can solve the problems of high maintenance cost, easy wear, difficult high-precision sealing, etc., to achieve the effect of small size and many planetary screen frame structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

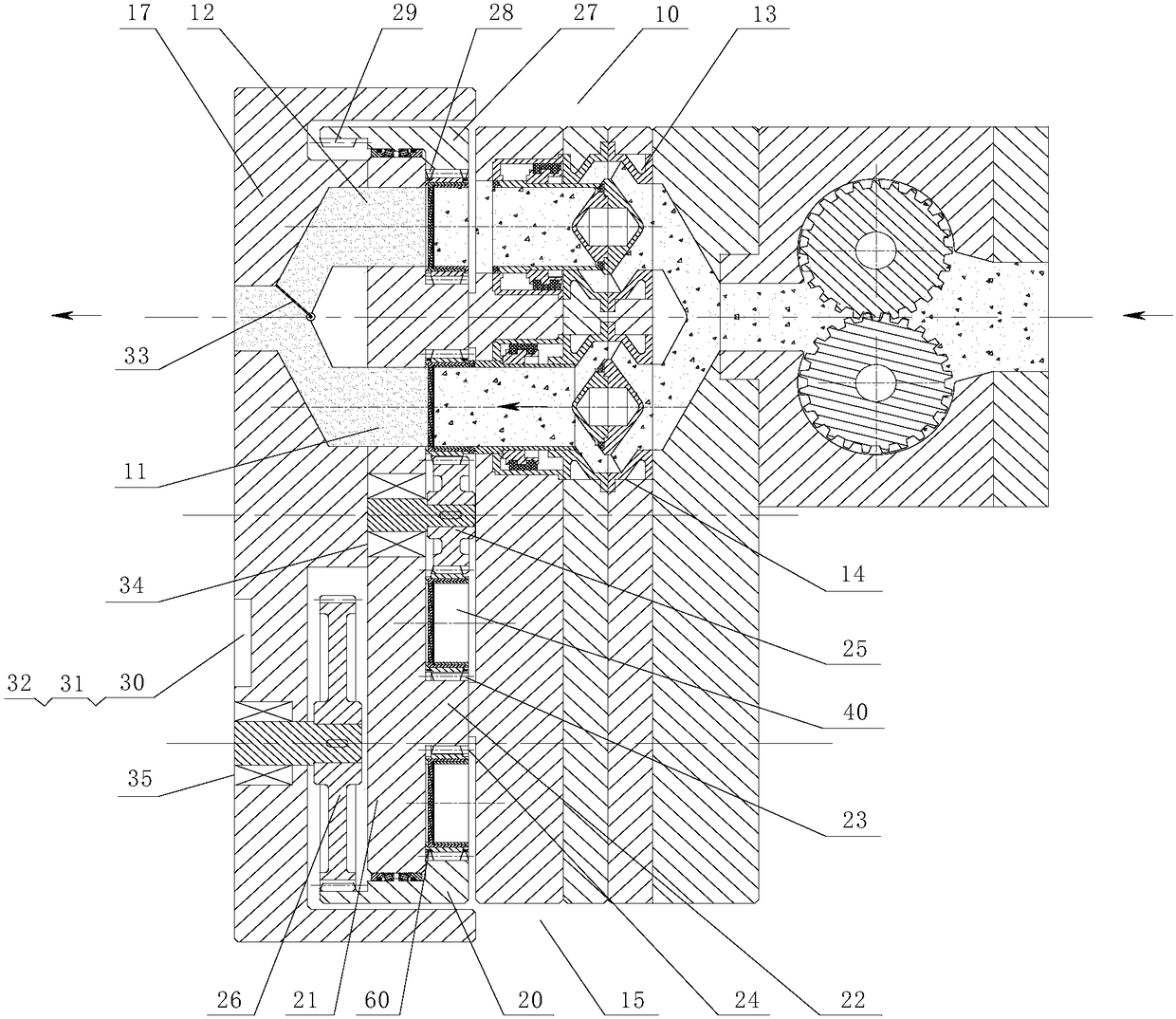

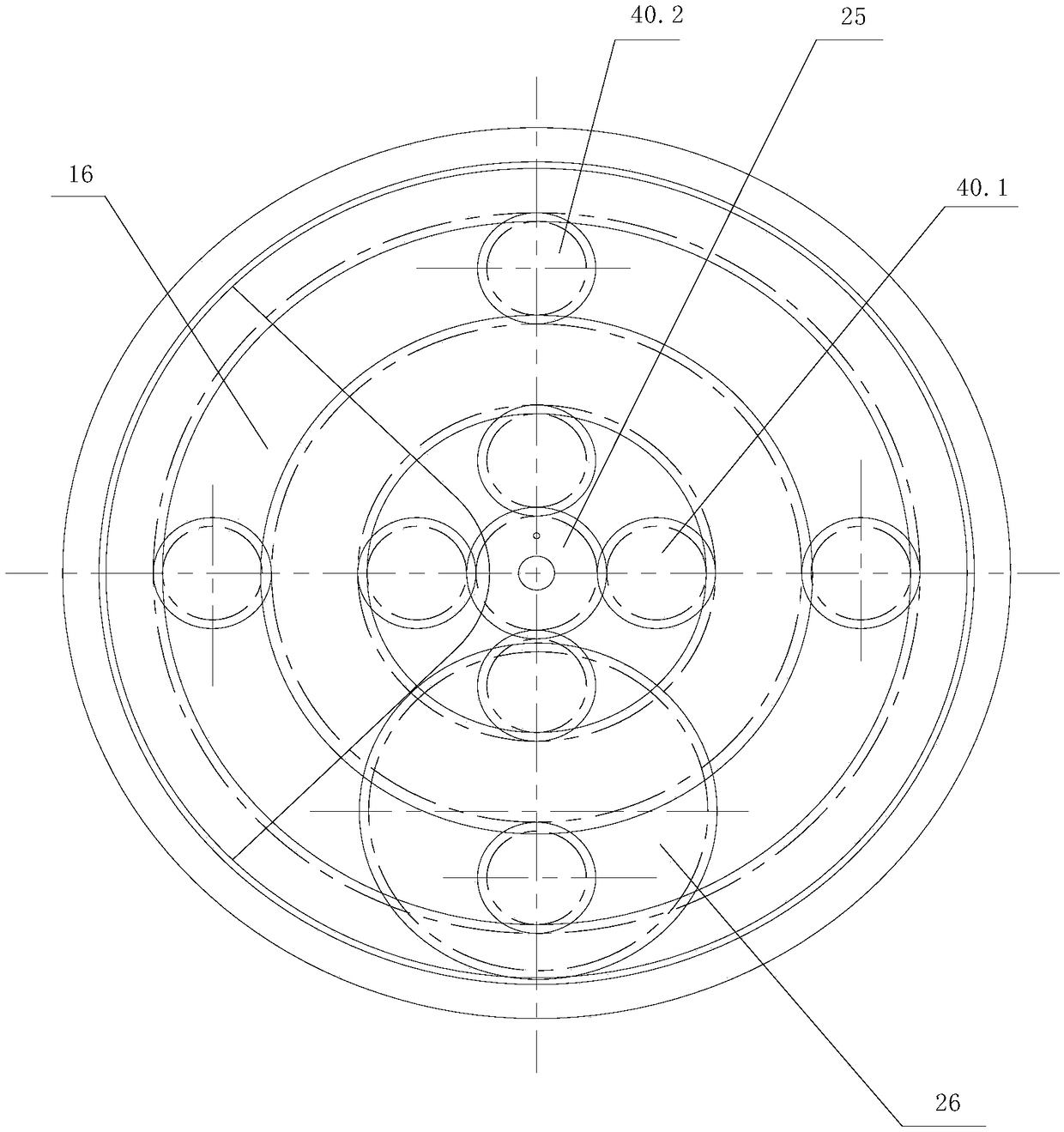

[0046] Such as Figure 1-4 As shown, an extruder filter screen automatic replacement device with continuous material flow includes a channel switching mechanism 10, a filter screen replacement mechanism 20 and an automatic control mechanism 30, and the channel switching mechanism 10 includes a first branch channel 11, a second The branch channels 12 , the first branch channel 11 is provided with a first channel valve 13 , the second branch channel 12 is provided with a second channel valve 14 , and the channel switching mechanism 10 is arranged in a channel plate 15 .

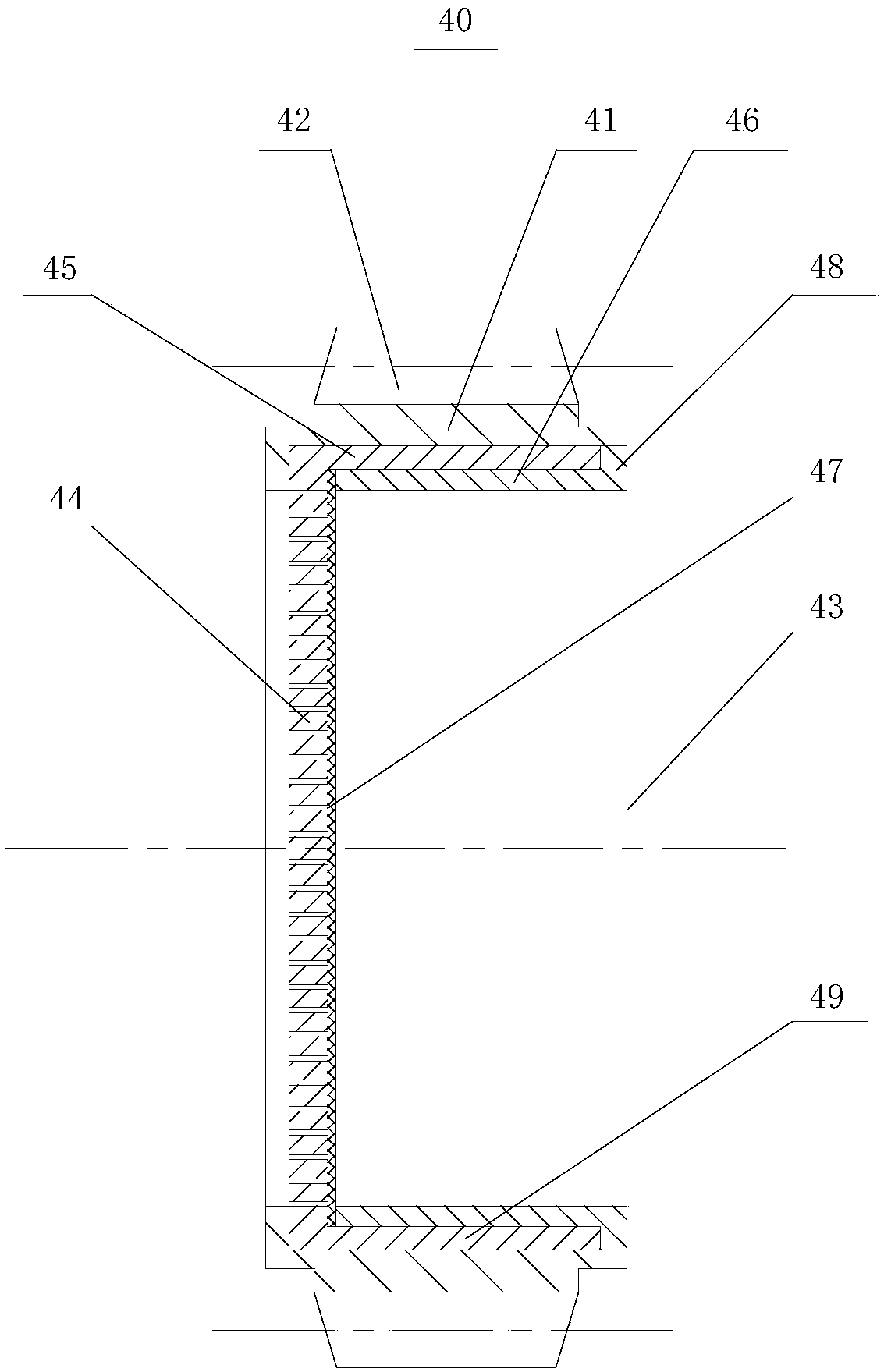

[0047] The filter replacement mechanism 20 includes a base 21, the back plate 24 is fixed on the lower surface of the base 21, the upper surface of the base 21 is provided with a raised ring gear part 22, and the inner hole wall of the raised ring gear part 22 is provided with a fixed inner ring gear 23, the outer cylindrical surface is provided with a fixed outer ring gear 24, the central axis of the base 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com