Apparatus and method for sterilizing closures for containers

A technology of seals and fungicides, which is used in the direction of tightly closing containers with lids, closures, bottle/container caps, etc., can solve the problems of loss of stability of seals, depending on the falling speed, machine failure, etc., and achieve a compact structure design. , the effect of high disinfection rate and high throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

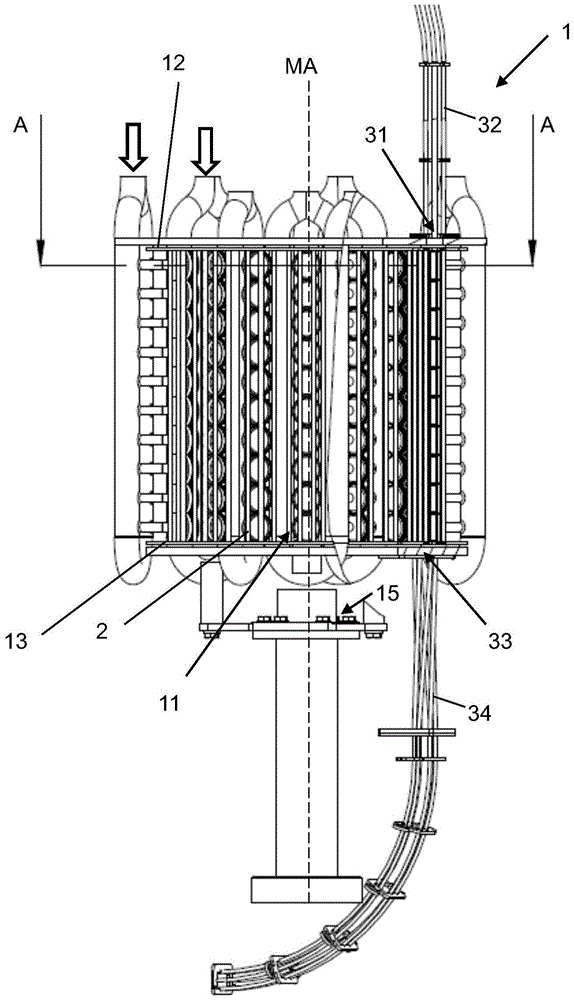

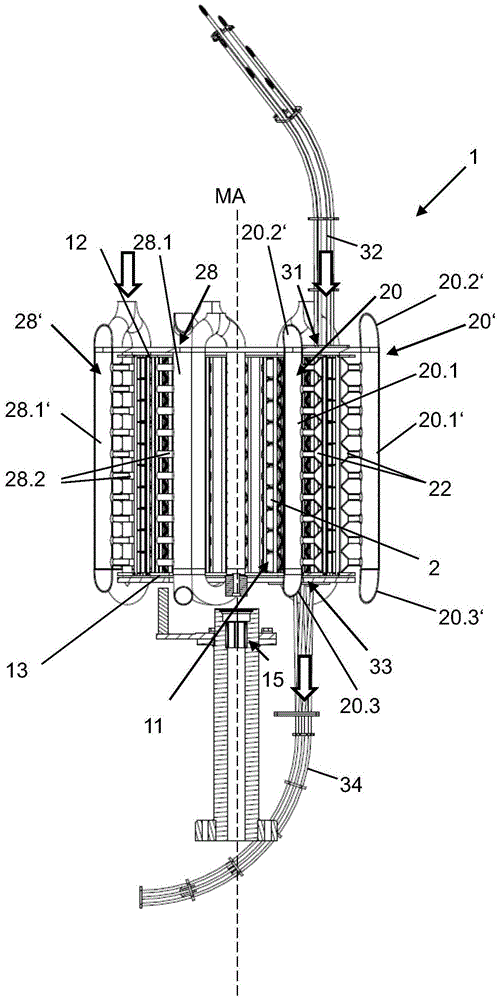

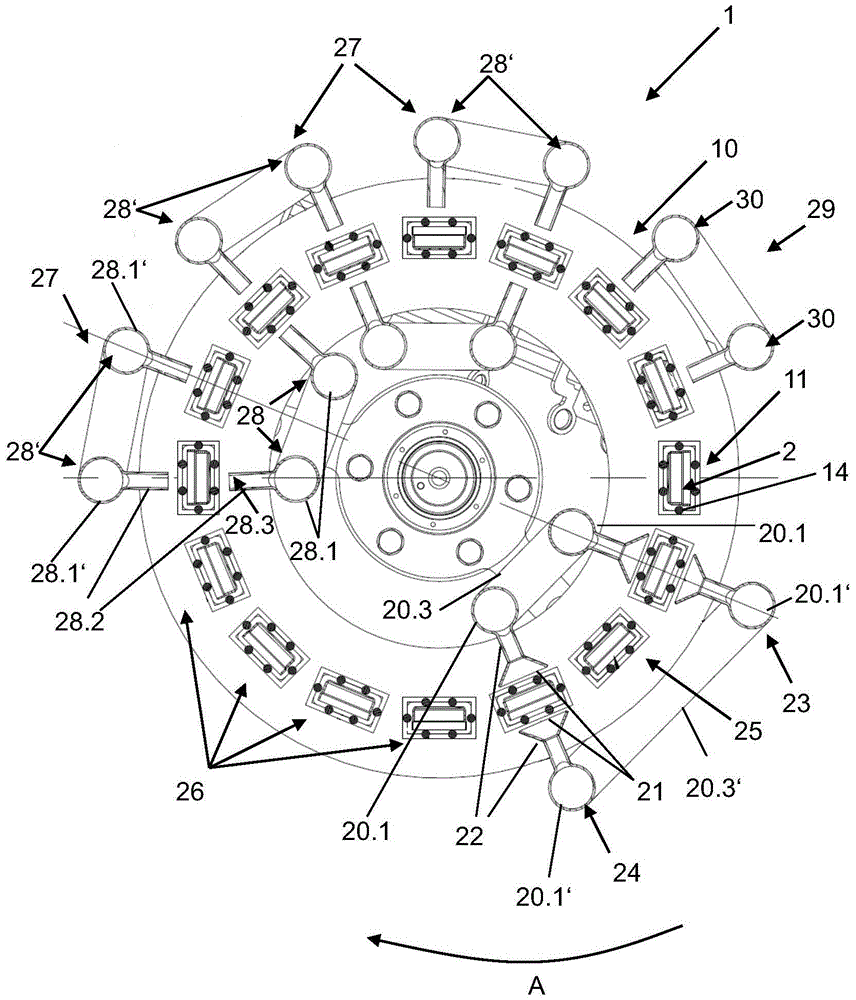

[0031] The device indicated generally by 1 in the figures is used to sterilize and / or sterilize seals 2, for example in the form of caps, threaded caps, sports caps, flat caps or crown plugs, which The member is used to seal a container (not shown), for example in the form of a bottle. To this end, the device 1 preferably forms a unit upstream of a sealing machine for sealing the containers, and the sterilized closure 2 is transferred from this unit to the sealing machine under sterile and / or clean conditions.

[0032] The device comprises, inter alia, a housing or casing (not otherwise shown in the figures), which has, for example, a polygonal or cylindrical shape surrounding a vertical machine axis or rotor axis MA, and in particular It can be configured in a hexagon. Apart from the inlet and outlet for the seal 2 , the interior of the housing is tightly sealed from the outside by the outer wall around the machine axis MA, by the upper and lower housing walls. Inspection w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com