Copper full needle-tube pen-point and processing technique

A processing technology, copper technology, applied in the field of copper full-needle pen head and its processing technology, can solve the problems of processing difficulties, reduce material costs, production costs, increase material costs, etc., achieve simplified processing, reduce processing costs, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

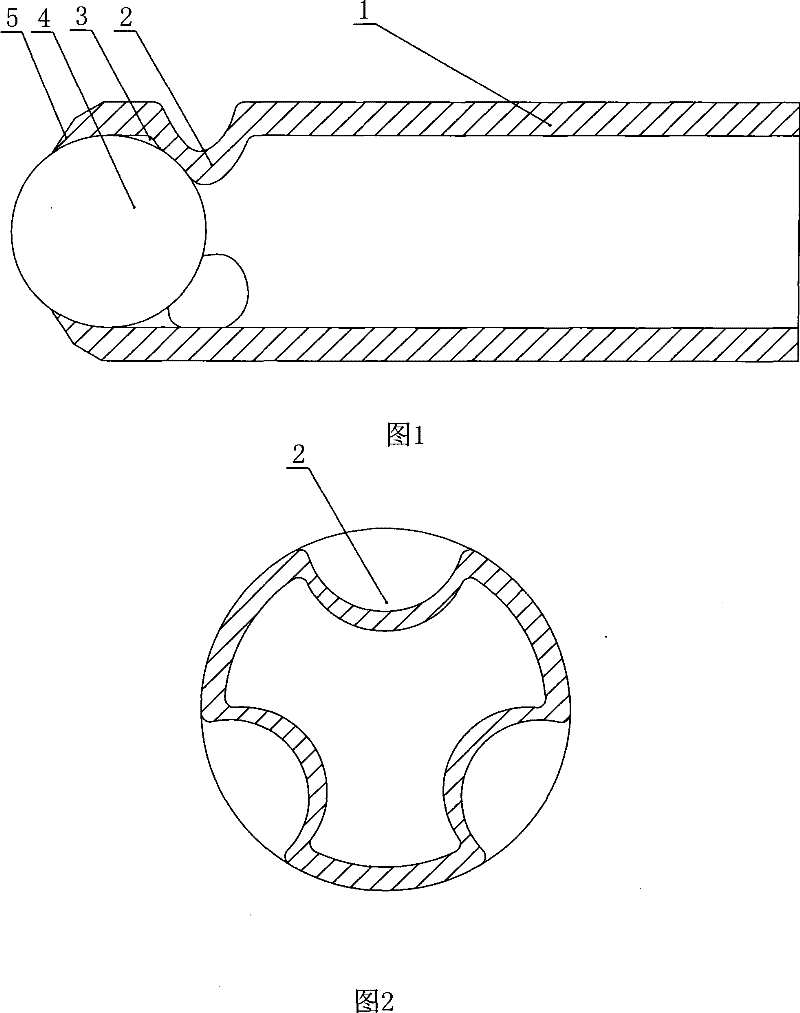

[0028] Embodiment 1: a kind of copper full needle tube nib 1 (see attached figure 1 attached figure 2 ), made of lead brass copper cylinder material, with an ink hole in the middle, a round hole cavity 3 at the end, balls 4 embedded in the hole cavity, and a closing hole 5 at the end of the hole cavity , fix the ball, the outer wall of the round hole cavity of the needle pen head is provided with three evenly distributed concave points 2, the inner wall of the concave point forms the bottom of the round hole cavity, and there is a gap between the inner walls of each concave point , the bottom of the concave cavity of the round hole is spherical, and a part of the spherical surface is on the inner wall of the concave point. The processing technology of the full needle tube pen tip includes the following steps:

[0029] 1.1 Select a copper cylinder with a diameter of 0.8mm to cut it off, and cut it into a needle tube with a length of 8mm;

[0030] 1.2 Clamp the cut copper cyl...

Embodiment 2

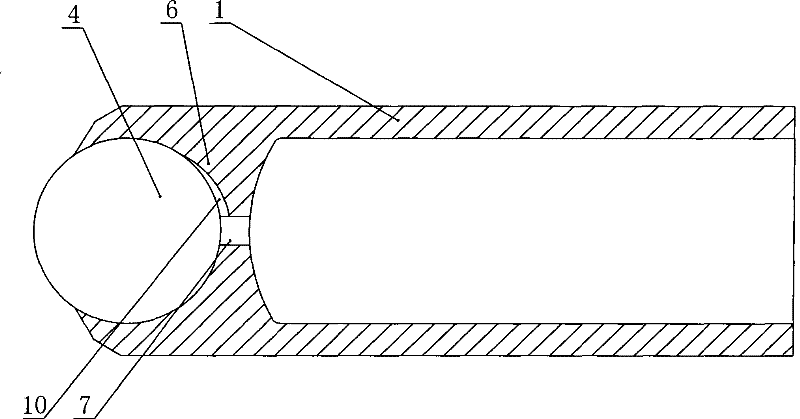

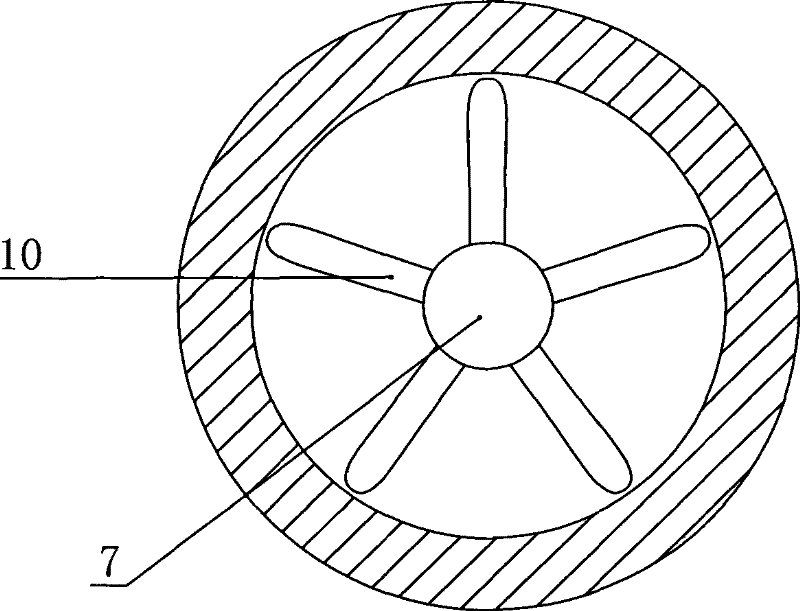

[0039] Embodiment 2: a kind of full needle tube nib (see attached image 3 attached Figure 4 ), made of copper cylindrical material, with an ink hole in the middle, a round hole cavity 3 at the end, a ball 4 embedded in the hole cavity, and the end of the hole cavity is a closing 5 to fix the ball , the bottom of the round hole cavity of the full-needle pen head is a closed part 6 with a small hole 7 in the middle, the bottom of the round hole cavity is spherical, and five grooves 10 communicated with the middle small hole are punched out on the spherical surface. The processing technology of the full-needle pen tip comprises the following steps:

[0040] 1.1 Select a copper cylinder with a diameter of 0.8mm to cut it off, and cut it into a needle tube with a length of 8mm;

[0041] 1.2 Clamp the cut copper cylinder on the machine tool, and drill the copper cylinder with a drill 8 with a diameter of 0.5mm and a section 9. When drilling, the copper cylinder rotates at a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com