Book conveying device of book cutting machine

A book cutting machine and book feeding technology, which is applied in metal processing and other directions, can solve the problems of affecting the appearance of books and uneven cutting of each page, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

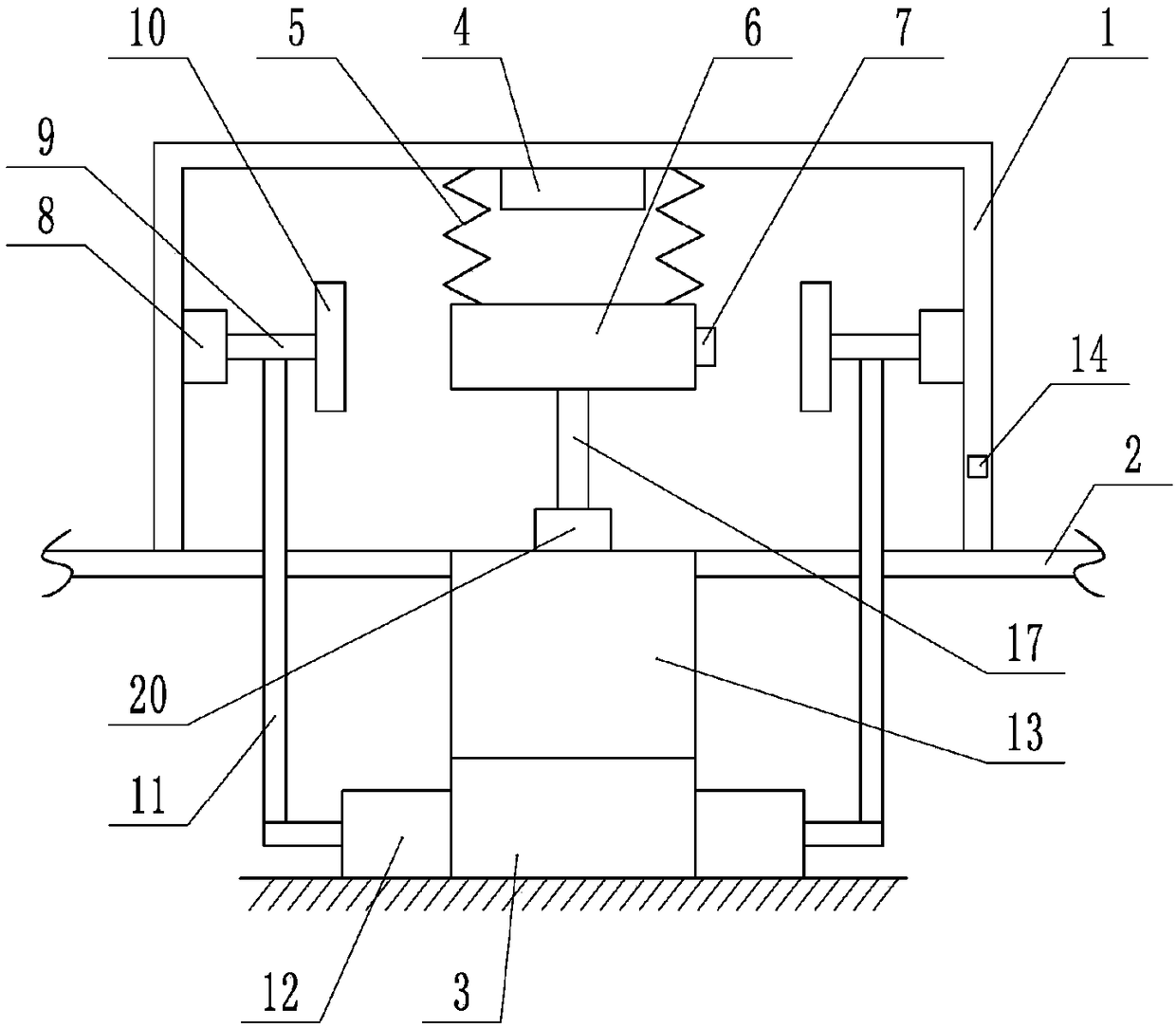

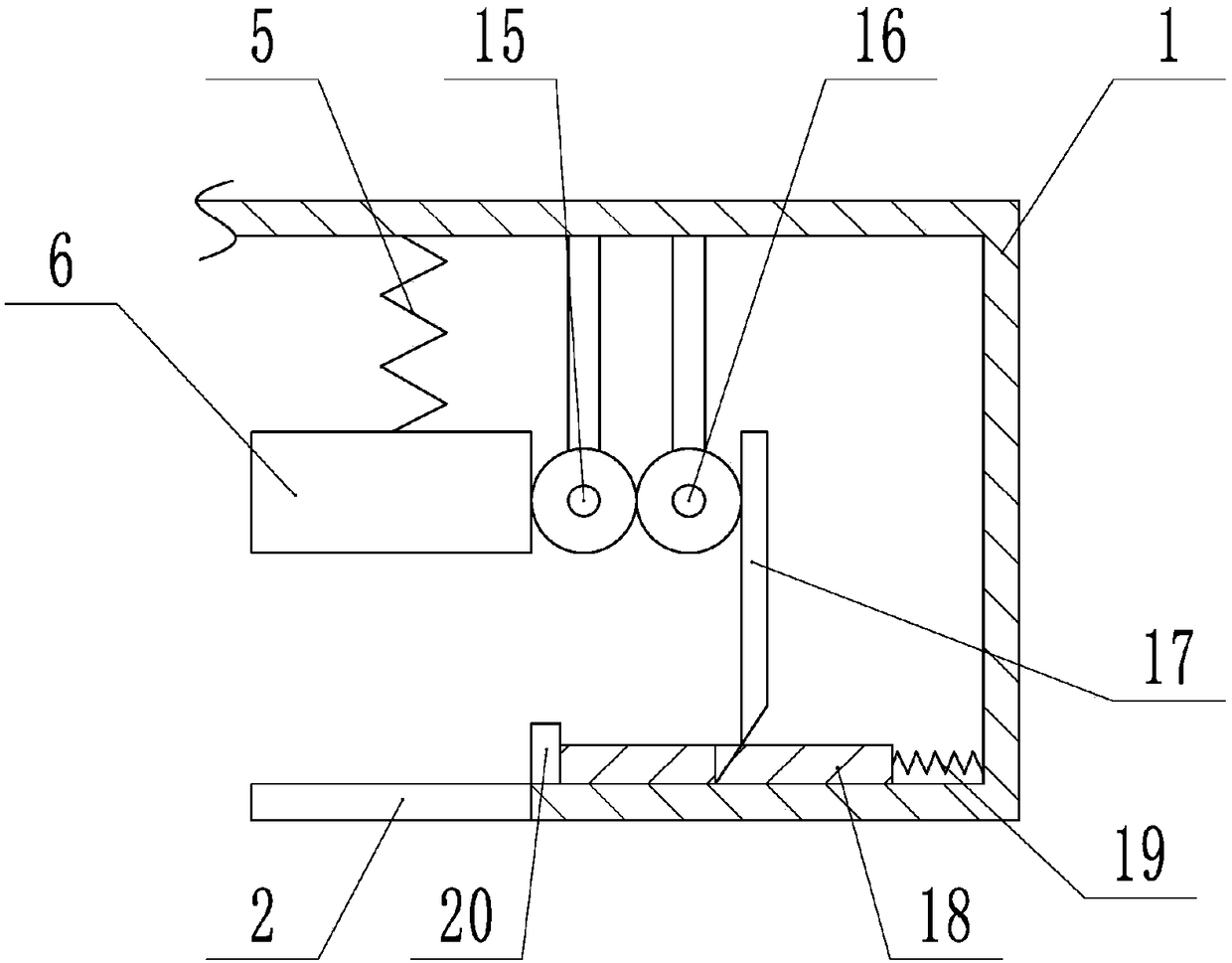

[0022] The reference signs in the drawings of the description include: frame 1, conveyor belt 2, workbench 3, electromagnet 4, first spring 5, magnetic pressing block 6, second switch 7, cylinder 8, pressing rod 9, splint 10 , connecting rod 11, piston cylinder 12, book delivery track 13, first switch 14, first gear 15, second gear 16, wedge bar 17, push rod 18, second spring 19, push plate 20.

[0023] like figure 1 As shown, the book feeding device of the shredder includes a frame 1, a conveyor belt 2 and a workbench 3. Two cylinders 8 are fixedly installed on both sides of the frame 1, and a pressure rod 9 is fixedly connected to the output shaft of the cylinder 8 to resist The end of the pressure rod 9 away from the cylinder 8 is welded with a splint 10, the end of the splint 10 away from the cylinder 8 is wrapped with a rubber layer, and a first switch 14 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com