Rotary cutting production device

A production device and rotary cutting technology, applied in metal processing and other directions, can solve the problems of wasting energy, high labor cost, low production efficiency, etc., and achieve the effect of satisfying collection and transfer, wide application area and good curved surface shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

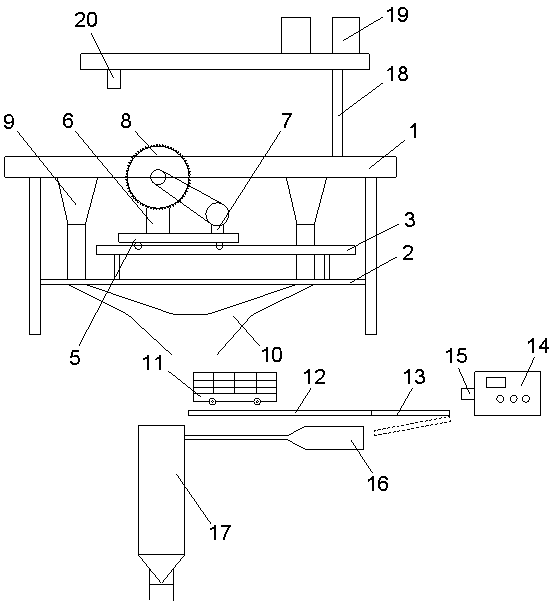

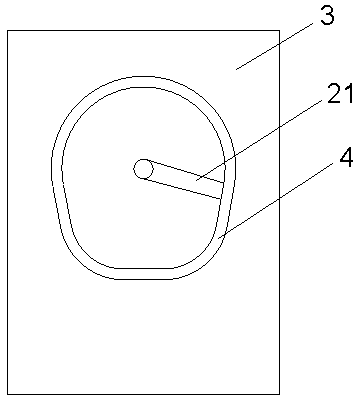

[0016] Such as figure 1 , 2 As shown, the present invention provides a rotary cutting production device, comprising a working table 1, a mounting plate 2 is arranged below the working table 1, a track table 3 is arranged on the mounting plate 2, a track 4 is arranged on the track table 3, and a track 4 A trolley 5 is arranged on the upper surface of the trolley 5, and a first bracket 6 and a second bracket 7 are arranged on the upper surface of the trolley 5. The first bracket 6 is provided with a driven wheel, and the second bracket 7 is provided with a driving wheel. The driving wheel is driven by a motor, and the driven wheel It is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com