A production method for controlling the warpage of strip steel in the finishing mill

A production method and finishing mill technology, applied in the direction of contour control, metal rolling, etc., can solve problems such as strip steel head flying warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

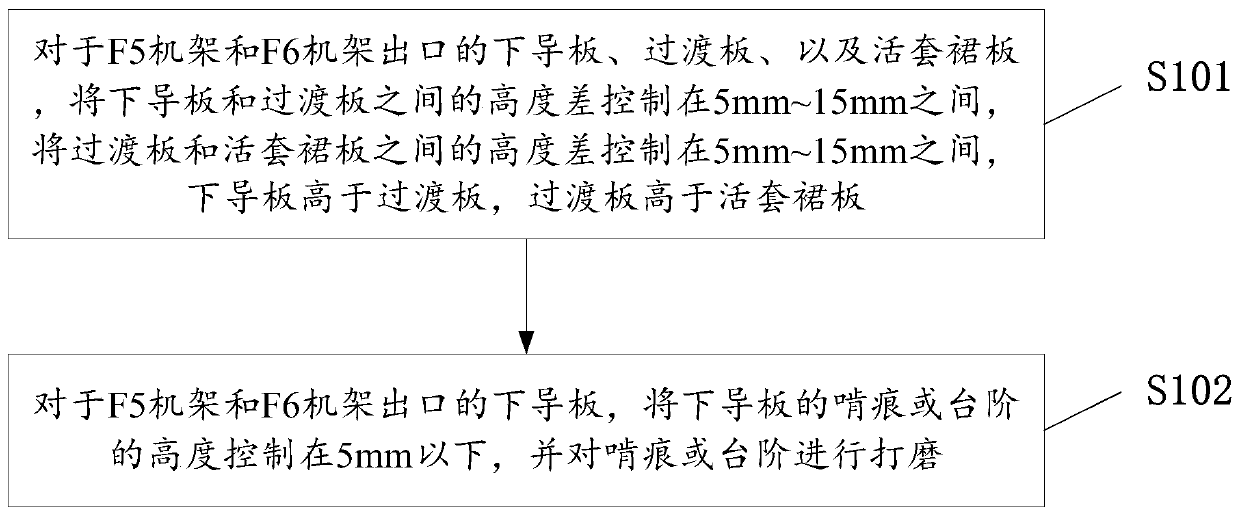

[0039] Such as figure 1 As shown, the present embodiment provides a production method for controlling strip flying in a finishing mill, including:

[0040] Step S101: For the lower guide plate, transition plate, and looper skirt at the outlet of the F5 frame and F6 frame, control the height difference between the lower guide plate and the transition plate between 5 mm and 15 mm, and place the transition plate and the looper skirt The height difference between them is controlled between 5mm and 15mm, the lower guide plate is higher than the transition plate, and the transition plate is higher than the looper skirt;

[0041] Step S102: For the lower guide plates at the outlets of the F5 and F6 racks, control the height of the gnawing marks or steps on the lower guide plate to less than 5 mm, and polish the gnawing marks or steps.

[0042] In the specific implementation process, the finishing mill unit has 7 stands in total, namely: F1 stand, F2 stand, F3 stand, F4 stand, F5 sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com