Semitransparent thin film solar cell and its preparation method

A thin-film solar cell, translucent technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of reduced carrier mobility, deterioration of thin-film cell performance, and increased cell resistance, to improve stability and device performance. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Pre-cut ITO conductive glass (Shenzhen South China Xiangcheng Technology Co., Ltd.) with square resistance ≤7Ω / □ and light transmittance ≥84% into rectangular sheets of 15mm×20mm. The rectangular slices were ultrasonically cleaned with deionized water, glass cleaner, acetone, alcohol, and deionized water for 15 minutes, and then dried with an air compressor for use.

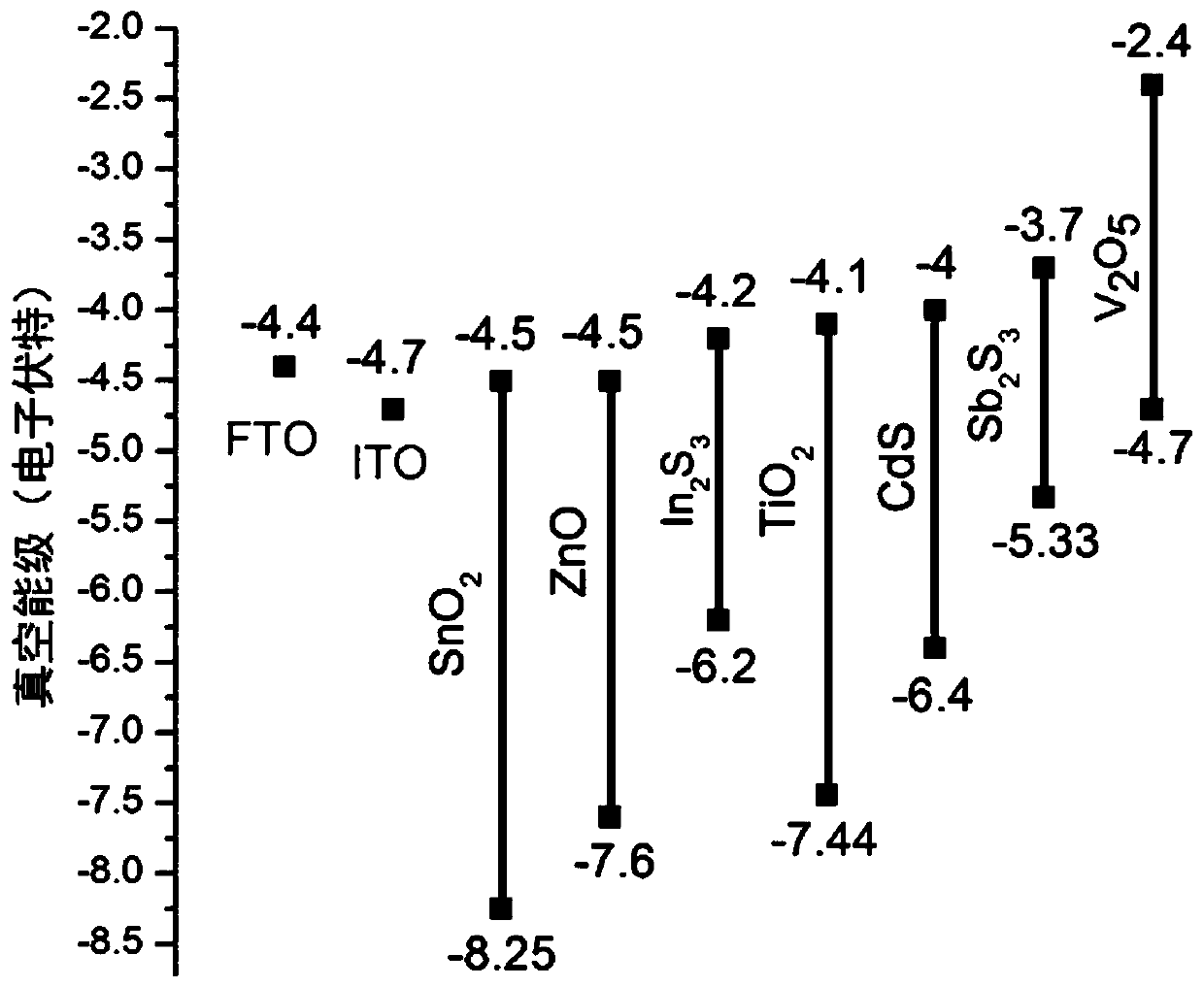

[0033] (2) On the ITO conductive glass to be used, spin-coat the electron transport layer with a KW-4A type spin coater, such as TiO 2 , ZnO, CdS, In 2 S 3 and SnO 2 any of them, please refer to figure 1 , the energy bands of these electron transport layers are similar to those of Sb 2 S 3 The energy band matching of the light absorbing layer.

[0034] Specifically, in this embodiment, spin-coated TiO 2 As an electron transport layer, the thickness is 40nm.

[0035] (3) The JGP450 high-vacuum magnetron sputtering system produced by Shenyang Scientific Instrument Co., Ltd. of the Chinese Academy...

Embodiment 2

[0047] (1) Pre-cut the FTO conductive glass (Wuhan Jingge Solar Technology Co., Ltd.) with a thickness of 2.2mm, a resistance of ≤14Ω / □, and a light transmittance of ≥90% into rectangular sheets of 15mm×20mm. The rectangular slices were ultrasonically cleaned with deionized water, glass cleaner, acetone, alcohol, and deionized water for 15 minutes, and then dried with an air compressor for use.

[0048] (2) A chemical water bath method is used to deposit a 50 nm CdS electron transport layer on the FTO conductive glass sheet to be used.

[0049] Specifically, 160 milliliters of deionized water was added to a 250 milliliter beaker, and then 0.03 mol / liter of cadmium sulfide solution, 1.5 mol / liter of thiourea and 14.5 milliliters of 25% ammonia were added to the beaker, Then put the beaker into a heat-collecting constant temperature heating magnetic stirrer and conduct a water bath at 80°C. After 3-6 minutes, the solution turns orange. After 8 minutes, a cadmium sulfide film of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com