Micro-shearing testing apparatus

A test device, micro-shearing technology, applied in the direction of measuring device, using stable shearing force to test material strength, test machinability, etc. Problems such as the accuracy of the shear strength value, to achieve the effect of precise matching, improved measurement accuracy, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

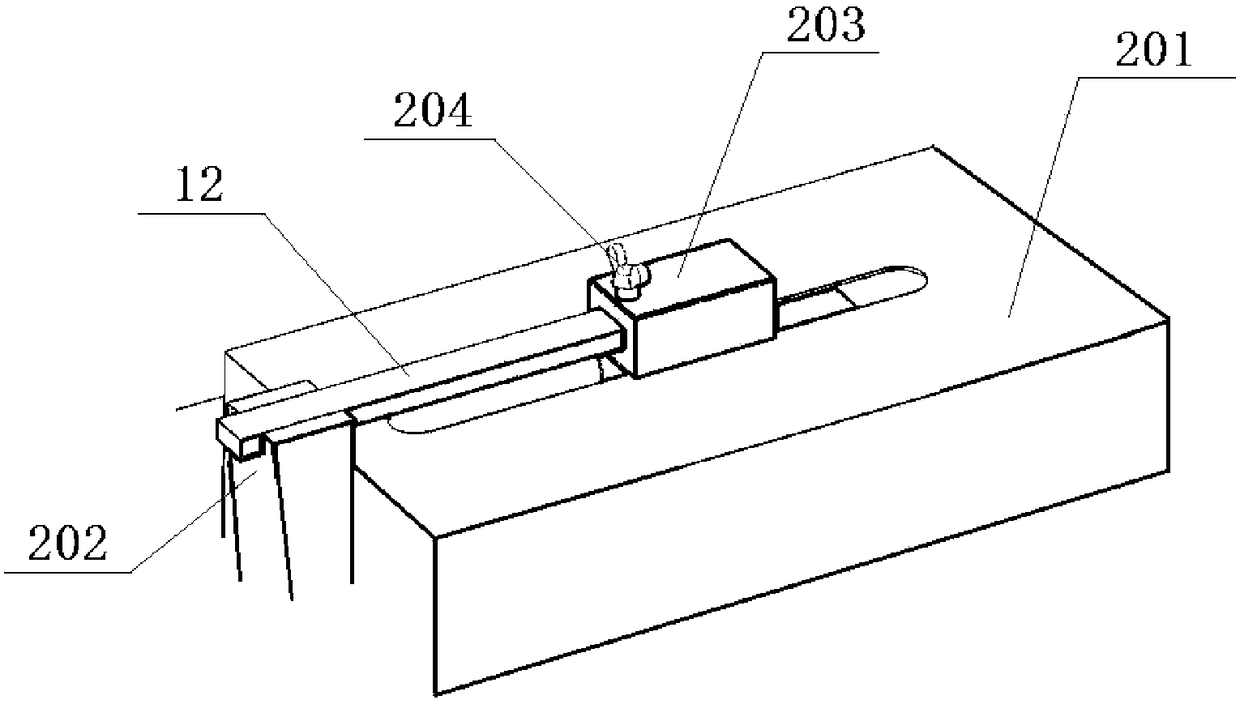

[0060] The embodiment of the present invention provides a kind of micro-shear test device, as attached figure 1 As shown, the device includes a base 1, and a sample fixing device 2 is arranged on the base 1, as shown in the attached figure 2 As shown, the sample fixing device 2 includes a sample support 201 arranged on the base 1, the front end of the sample support 201 is provided with a front clamping block 202, and the rear end is provided with a rear clamping block 203; the device also includes a tool 3, as attached image 3As shown, the knife 3 includes a knife handle 301 connected to the tensile testing machine 11 , and a knife head 302 disposed at the bottom of the knife handle 301 . The base 1 is provided with a frame 4 located at the front end of the sample fixing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com