Quantitative feeding device, feeding equipment and 3D (3-Dimensional) printing equipment

A feeding device and feeding equipment technology, applied in the field of 3D printing, can solve problems such as troublesome weighing and inconsistent addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

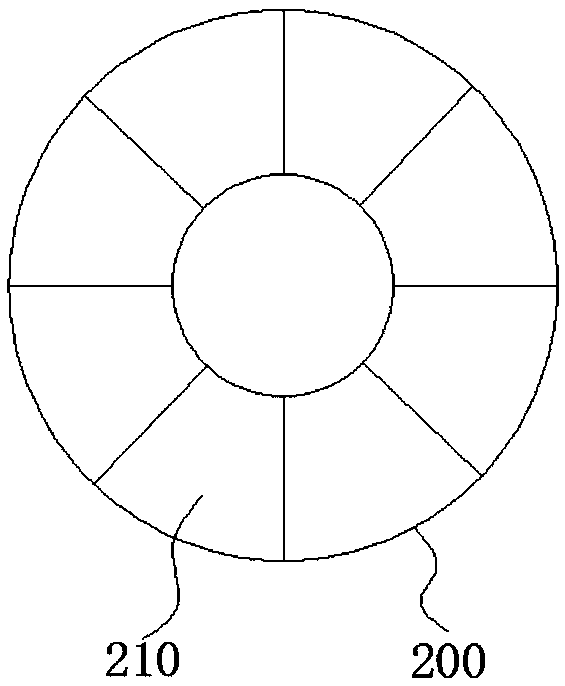

[0043] Such as Figure 1 to Figure 3 As shown, the first embodiment provides a quantitative feeding device, including: an auxiliary hopper unit, the auxiliary hopper unit includes a storage bin 100 and a quantitative discharge assembly; wherein, the storage bin 100 has a bin body and a bin bottom, and the bin bottom The inner end surface 110 is an inclined plane with one end higher than the other end, wherein the lower end is provided with a first outlet; the quantitative discharge assembly includes a rotary bin 200 with upper and lower ends open and a plurality of partitions 210, and the rotary bin 200 can be relatively The storage bin 100 rotates so that a partition grid 210 is arranged opposite to the first outlet; A partition grid 210 corresponds to the second outlet, and the first outlet is arranged above the second outlet and offset from the second outlet.

[0044] In this quantitative feeding device, materials are placed in the storage bin 100. When in use, since the r...

Embodiment 2

[0068] Such as Figure 1 to Figure 5 As shown, the second embodiment provides a feeding device, including: a main hopper unit and the quantitative feeding device in the first embodiment above.

[0069] Wherein, the main hopper unit includes a main hopper 500 for mixing materials. The main hopper 500 includes: a main material inlet 510 and a main material outlet 520 . The second outlet on the bottom plate 220 communicates with the main hopper 500 .

[0070] The feeding equipment includes the above-mentioned quantitative feeding device, wherein the specific structure, connection relationship and beneficial effects of the quantitative feeding device have been described in detail in the above text, and will not be repeated here.

[0071] In the feeding equipment, such as Figure 4 and Figure 5 As shown, the main material inlet 510 is used to put in the main material, the quantitative feeding device quantitatively and regularly sends the auxiliary material through the second out...

Embodiment 3

[0082] The third embodiment provides a 3D printing device, including: the feeding device in the second embodiment above.

[0083] The 3D printing equipment includes the above-mentioned feeding equipment, wherein the feeding equipment includes the above-mentioned quantitative feeding device, the specific structure, connection relationship and beneficial effects of the quantitative feeding device have been described in detail in the above text, and will not be repeated here. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com