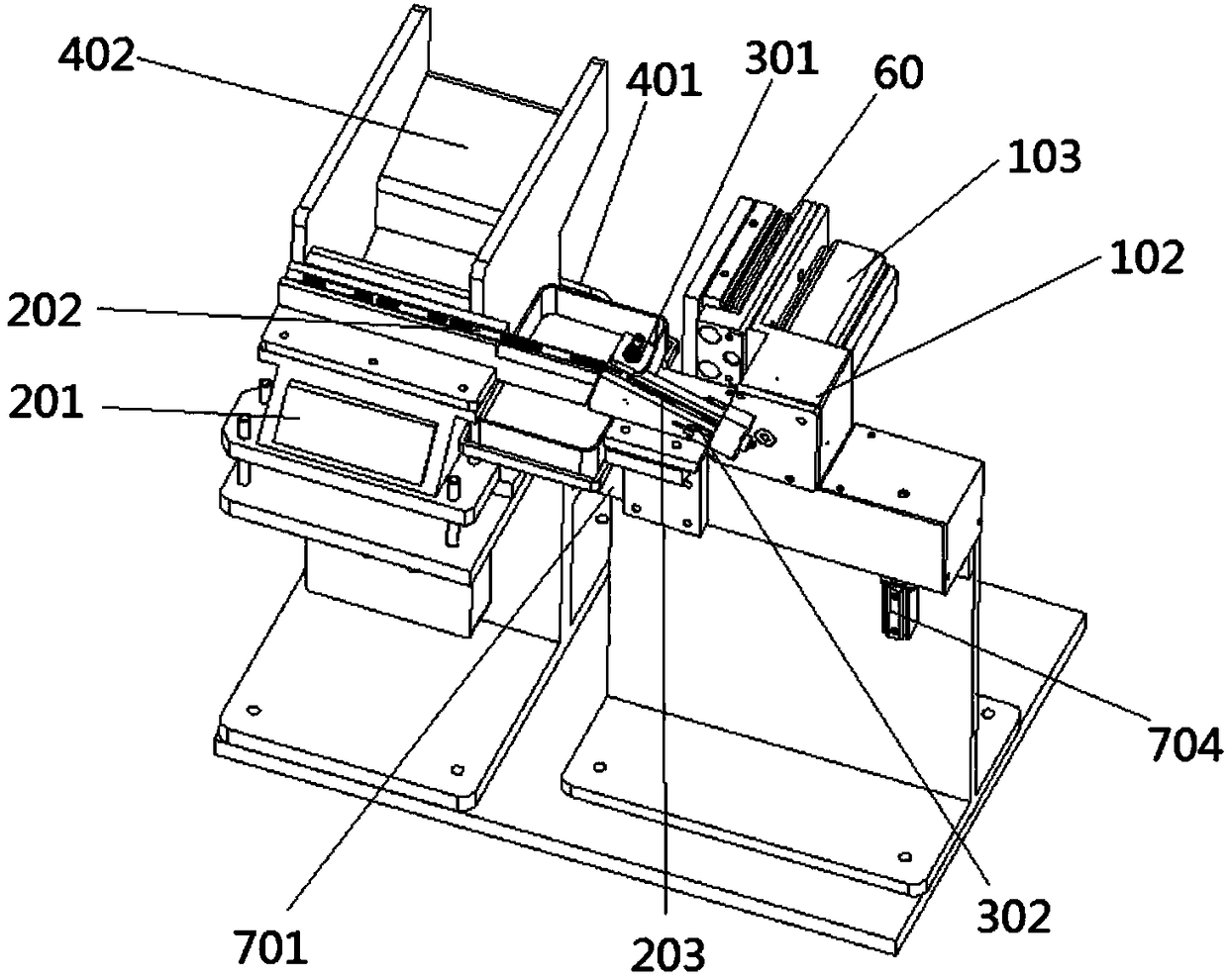

Turnover mechanism and double-end bolt orientation arrangement device

A technology of stud bolts and directional arrangement, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of wrong arrangement direction of stud bolts, complex structure of turning mechanism, and unobvious features at both ends, etc., to achieve fast detection , simple and safe structure, and the effect of streamlining the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in combination with specific embodiments.

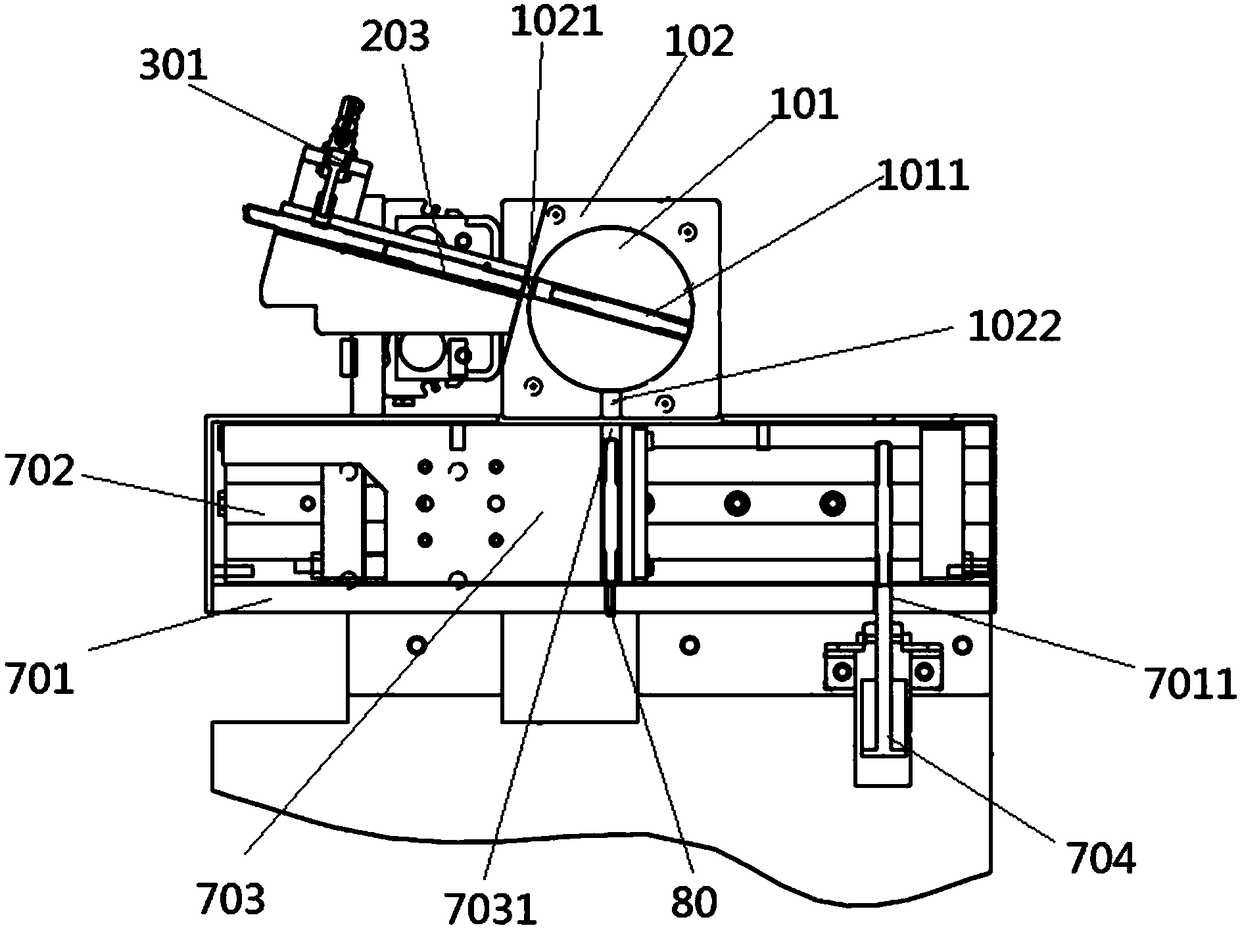

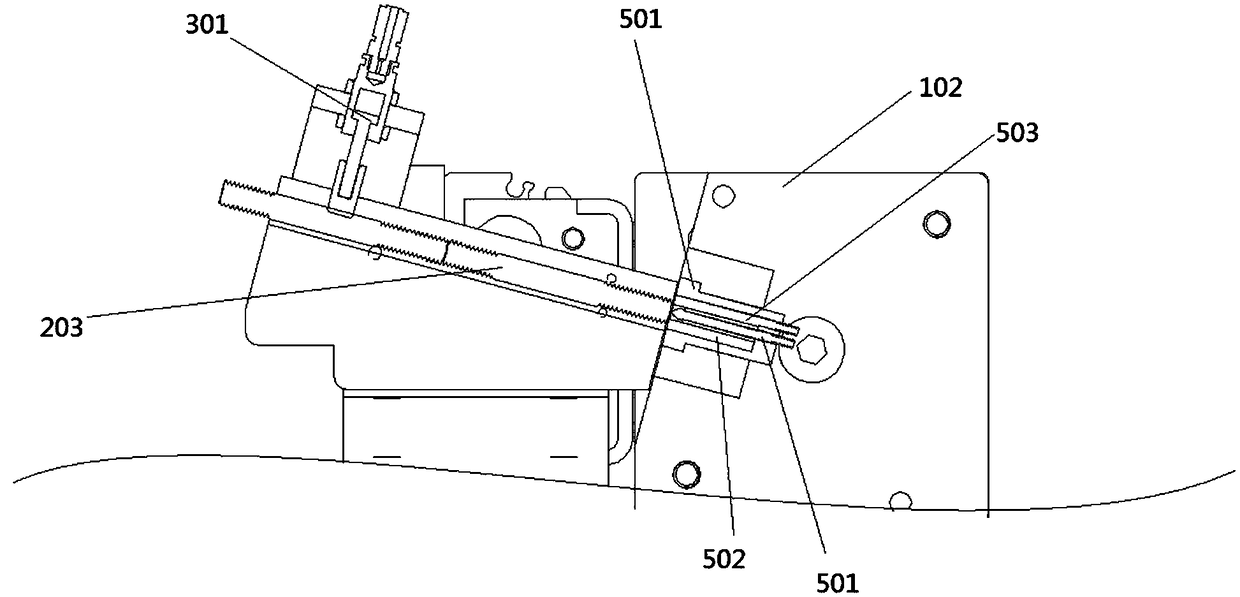

[0027] As one of the implementations of the present invention, this specific embodiment provides an overturning structure. The overturning structure includes a rotating disk 101 with accommodating through holes 1011 in the radial direction, a rotating base plate 102 with a mounting groove in the middle, and a driving rotation The motor that rotates the disk 101, the rotating disk 101 is fitted in the installation groove; the upper side wall of the installation groove is provided with a feed through hole 1021 coaxial with the accommodation through hole 1011; the diameter of the feed through hole 1021 is equal to the accommodation through hole 1011 .

[0028] Take the horizontal axis of the installation groove as the boundary, upwards is the upper part, and downwards is the lower part.

[0029] Working principle: The stud bolts enter the accommodation through hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com