Mould wiring testing device, system and method

A test device and mold technology, applied in the field of measuring instruments, can solve the problems of wrong wiring, inconvenience, inaccuracy, etc., and achieve the effects of low error rate, convenient positioning, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention, so that the advantages and characteristics of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention Make a clearer definition.

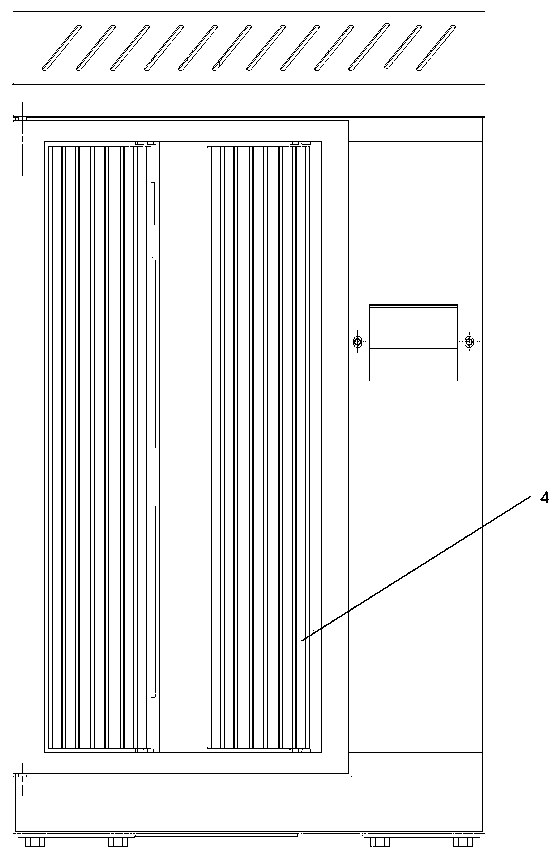

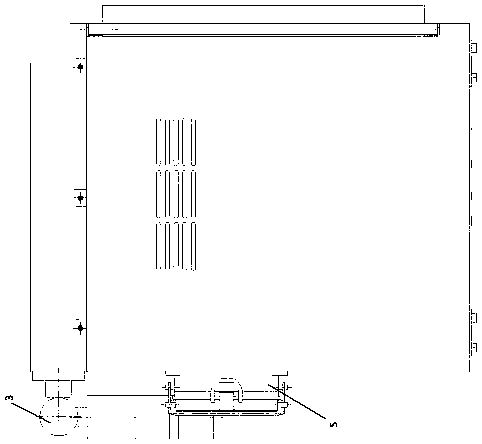

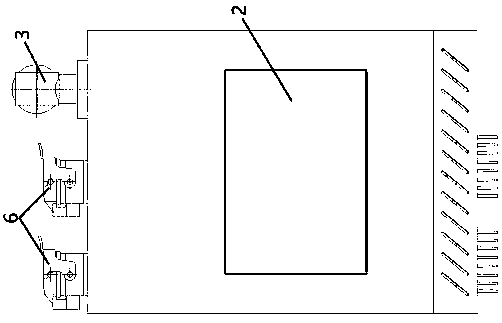

[0029] Such as Figure 1~Figure 4 As shown, the present invention discloses a mold wiring testing device, which includes a box body 1, a touch display 2, a control alarm component 3, a heat dissipation plate 4, a control board and a wiring seat 5, and the touch display 2 is arranged on the box body 1 The top of the box body, the cooling plate 4 is located at the front of the box body 1, the terminal block 5 is located at the back side of the box body 1, the control alarm part 3 is arranged on the back side of the box body 1 near the top of the box body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com