Preparation method of coal-series reservoir group fracturing object model sample taking transition zone into account

A transitional zone and coal series technology, applied in the field of rock sample preparation, can solve problems such as inability to perform accurate simulations, and achieve the effects of saving raw materials, improving efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

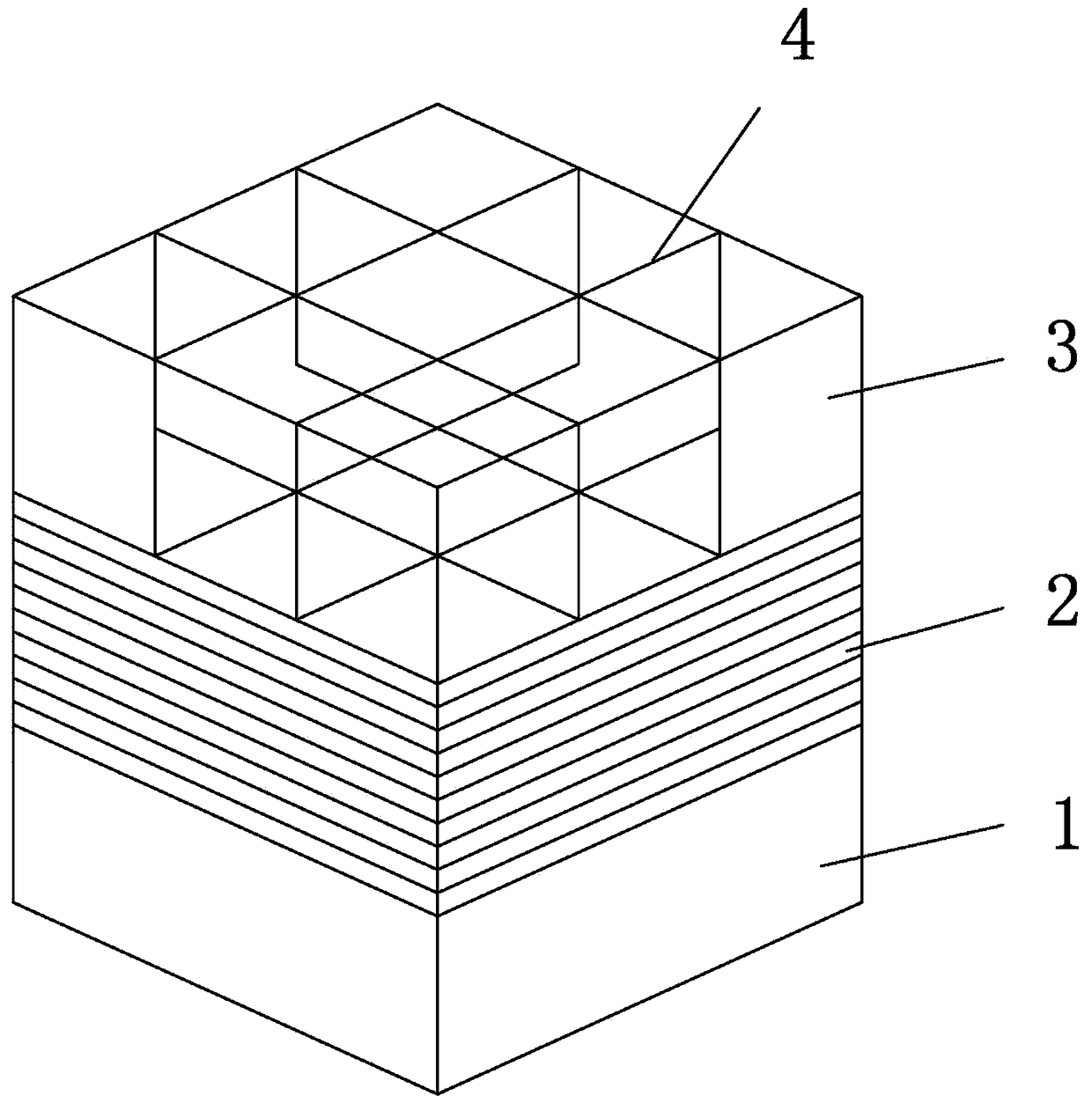

[0030] Such as figure 1 As shown, according to an embodiment of the preparation method of the fracturing model sample of the coal-measure production layer group considering the transition zone of the present invention, it comprises the following steps in sequence:

[0031] Step 1: Place the sample mold on a horizontal surface; mix cement and quartz sand evenly according to a certain proportion, add water to the mixture and stir to form cement slurry; pour the cement slurry on the bottom layer of the sample mold to form coal Rock layer 1 of the production formation;

[0032] Step 2: Mix cement, quartz sand, and coal powder evenly according to a certain proportion, add water to the mixture and stir to form a coal-containing slurry; prepare ten parts of coal-containing slurry containing different proportions of coal powder, from small to large according to the proportion of coal powder The sequence is poured layer by layer in the middle layer of the sample mold, which forms the ...

Embodiment 2

[0042] According to another embodiment of the preparation method of the fracturing model sample of the coal-measure production layer group considering the transition zone of the present invention, its specific steps, preparation principle, beneficial effect, etc. are all the same as the first embodiment, the difference is:

[0043] The particle size of described quartz sand is 120 orders;

[0044] In step 1, the mass of water added to the cement slurry is 25% of the total mass of cement and quartz sand. The pouring height of the cement slurry in the sample mold is 50 mm.

[0045] In step 2, the volume ratios of cement, quartz sand, and coal powder in ten parts of coal-containing slurry are 1:1:0.15, 1:1:0.25, 1:1:0.45, 1 :1:0.8, 1:1:1.3, 1:1:1.8, 1:1:2.6, 1:1:3.4, 1:1:3.9, 1:1:4.25. The mass of water added to each portion of the coal-containing slurry is 20% of the total mass of cement, quartz sand, and coal powder in the portion of the coal-containing slurry. Coal-containi...

Embodiment 3

[0049] According to another embodiment of the preparation method of the fracturing model sample of the coal-measure production layer group considering the transition zone of the present invention, its specific steps, preparation principle, beneficial effect, etc. are all the same as the first embodiment, the difference is:

[0050] The particle size of described quartz sand is 100 orders;

[0051] In step 1, the mass of water added to the cement slurry is 20% of the total mass of cement and quartz sand. The pouring height of the cement slurry in the sample mold is 80 mm.

[0052] In step 2, the volume ratios of cement, quartz sand, and coal powder in ten parts of coal-containing slurry are 1:1:0.1, 1:1:0.2, 1:1:0.35, 1 :1:0.6, 1:1:1.0, 1:1:1.5, 1:1:2.2, 1:1:3.0, 1:1:3.6, 1:1:4.1. The mass of water added to each portion of the coal-containing slurry is 15% of the total mass of cement, quartz sand, and coal powder in the portion of the coal-containing slurry. Coal-containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com